Building information modeling (BIM) plays a key role in design and construction. Its value, however, extends beyond project handover. Today, BIM data combined with a facility management solution (BIM for FM) gives teams the insights they need to manage buildings efficiently and strategically.

For facility and maintenance professionals, BIM for FM isn’t just about managing assets, though. It can also be a tool for onboarding new team members into complex environments. By providing accurate, visual, and data-rich models of building systems, BIM helps new hires understand the spaces they’ll maintain, the equipment they’ll service, and the workflows they’ll follow.

Key takeaways

- By providing interactive 3D models and centralized data, BIM helps new hires understand complex building systems quickly, reducing training time and errors

- BIM for FM shifts teams from intuition to insight by offering dashboards, predictive maintenance alerts, and analytics that make data central to operations

- A shared BIM model connects finance, IT, compliance, and operations, breaking down silos and enabling coordinated strategies for maintenance, energy efficiency, and safety

BIM for FM helps you accelerate learning, support cross-departmental coordination, and help your team make the shift to a data-first mindset.

What is BIM for FM?

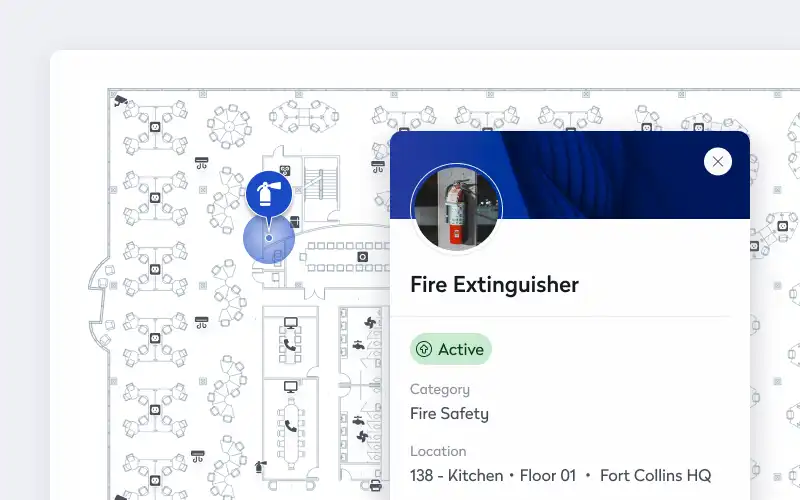

BIM is a digital representation of a building that goes far beyond its role in design and construction. For facility managers, BIM data becomes part of a centralized source of truth, combining detailed models with critical data on assets, spaces, and systems. Integration allows teams to access accurate information for everything from floor layouts to equipment specifications, creating a foundation for smarter, more efficient operations.

Instead of relying on static drawings or scattered documents, BIM for FM delivers a dynamic database that supports proactive strategies. Facility teams can use it to plan preventive maintenance, track asset life cycles, and adapt spaces without costly physical changes.

By turning complex building data into actionable insights, organizations can reduce downtime, improve collaboration, and make informed decisions about energy use, and capital investments.

How can training and onboarding become a competitive advantage with BIM for FM?

Onboarding new team members in facility management and maintenance can be complex. They need to understand building systems, compliance requirements, and operational workflows before they can perform confidently. You can use BIM for FM to make the process faster and more effective by giving new hires access to accurate, visual, and data-rich models of the spaces they’ll maintain.

Instead of relying on paper manuals or scattered spreadsheets, BIM provides a single source of truth for everything from asset details to emergency procedures. This approach turns onboarding into an interactive experience that helps employees learn about the facility even before they ever set foot on-site.

Creating immersive learning through interactive models

Interactive models allow new hires to explore facilities virtually before stepping on-site. They can walk through every pipe, wire, and structural element in a safe, digital environment.

In manufacturing, this means technicians can learn production line layouts without halting operations. CRE property managers can preview HVAC systems and fire safety routes before taking over a building. In the energy sector, engineers can study complex piping networks and safety zones remotely, reducing onboarding time and minimizing risk.

The payoff is significant: immersive learning can reduce training time by 75% and improve knowledge retention by 50%, according to the PwC “VR Soft Skills Training Efficacy Study.”

Delivering role-specific insights with tailored dashboards

Generic training can overwhelm employees. BIM helps you solve this with dashboards customized for each role. Technicians see maintenance schedules, asset histories, and real-time performance data, while managers access budget forecasts and strategic KPIs.

For example, in manufacturing, a maintenance lead might track machine uptime and warranty data. In CRE, a facilities director monitors occupancy trends and energy consumption, while in the energy sector, dashboards highlight compliance metrics and predictive maintenance alerts for critical equipment.

Building confidence through scenario-based simulations

Emergencies don’t wait for training sessions. BIM enables realistic what-if simulations, from equipment failures to evacuation drills. Teams can practice responses in a controlled environment, sharpening decision-making before real-world challenges arise.

In manufacturing, this might mean simulating a conveyor belt breakdown and planning rapid repairs. CRE teams can rehearse fire evacuation routes for high-rise properties. In the energy sector, simulations prepare crews for pipeline leaks or power outages, ensuring safety and compliance under pressure.

Virtual simulations also cut costs: companies using VR-based training report 50% lower training expenses and 43% fewer accidents compared to traditional methods, according to Training Industry research.

In the end, using BIM for FM to onboard new facility and maintenance team members isn’t about teaching them the software. It’s about teaching them all about the building.

How does BIM for FM help teams move to a data-first mindset?

BIM for FM does more than organize building information. It also helps teams embrace data-driven decision-making. For new technicians, it sets the tone from day one, while for experienced staff it provides tools that make data central to every choice.

Using BIM for FM to onboard new technicians into a data-focused culture

Onboarding in facility management often relies on shadowing and paper-based manuals. BIM for FM changes that by giving new hires immediate access to accurate, visual models of the spaces they’ll manage.

In manufacturing, a technician can review equipment layouts and maintenance histories before stepping onto the production floor, reducing downtime during training. In commercial real estate, property managers can explore HVAC systems and fire safety routes virtually, learning how data informs energy efficiency and compliance. In the energy sector, engineers can study pipeline networks and safety zones through interactive models, reinforcing the importance of data for risk management.

Helping experienced team members shift from intuition to insight

For more seasoned technicians, habits often lean on experience rather than evidence. BIM for FM provides dashboards and analytics that make data the default for planning and decision-making.

In manufacturing, predictive maintenance alerts help teams schedule repairs before failures occur, reducing costly downtime. In CRE, dashboards track occupancy trends and energy consumption, enabling managers to justify capital investments with hard numbers. In the energy sector, compliance metrics and performance data support proactive safety measures, replacing reactive fixes with informed strategies.

The result is a team that works with confidence, collaborates effectively, and uses data to drive measurable improvements across operations.

How does BIM for FM re-enforce the value of collaboration across departments?

Facility management touches nearly every part of an organization, including finance, IT, compliance, and operations. Yet, many teams still work in silos, which leads to inefficiencies and missed opportunities.

BIM for FM helps you change that by making collaboration visible and practical. When everyone works from the same centralized model, it becomes clear how interconnected their roles are and why shared data matters.

Teaching collaboration at onboarding

New technicians often see their responsibilities as limited to repairs and inspections. BIM for FM helps them understand the bigger picture.

For example, in manufacturing, preventive maintenance schedules tied to production timelines show how their work prevents costly downtime. In commercial real estate, accurate space data supports leasing strategies and energy audits, connecting maintenance decisions to revenue and sustainability goals. In the energy sector, compliance records stored in BIM reduce reporting delays for safety teams, reinforcing why coordination matters.

Reinforcing collaboration for experienced staff

For seasoned staff, BIM for FM provides tools that make interdepartmental coordination easier and more transparent. Dashboards can display budget forecasts for finance, energy performance metrics for sustainability teams, and compliance data for risk managers that’s all from the same model.

In CRE, facility managers can share real-time occupancy data with workplace strategists to optimize space planning. In manufacturing, maintenance teams can collaborate with operations to schedule repairs without disrupting production. In the energy sector, BIM helps align safety protocols with engineering updates, reducing risk, and improving audit readiness.

Connecting design and operations: Autodesk and Eptura Alliance

Together, Autodesk and Eptura create a unified ecosystem that connects BIM data with operational workflows, enabling organizations to manage the entire building lifecycle more effectively.

The strategic integration of Autodesk’s digital twin technology with Eptura’s worktech platform creates a seamless flow of information from design and construction into day-to-day facility management. Facility teams can access accurate models, asset data, and performance insights in one place, reducing inefficiencies that often occur during handover.

By combining design intelligence with operational data, the partnership empowers organizations to optimize space utilization, improve maintenance planning, and enhance sustainability efforts—all while ensuring that buildings operate as intended throughout their lifecycle.

For facility leaders, this collaboration reinforces the broader benefits of BIM in operations. It’s not just about having detailed models. It’s also about making those models actionable.

Driving facility management forward with BIM for FM

Building information modeling for facility management becomes a strategic enabler. By centralizing accurate building data and integrating it with immersive training and collaborative tools, organizations can reduce risk, improve efficiency, and strengthen decision-making. Whether it’s accelerating onboarding, fostering a data-first culture, or breaking down departmental silos, BIM for FM equips teams to manage complexity with confidence and precision. For facility leaders, adopting BIM for FM helps position your organization for long-term operational excellence.