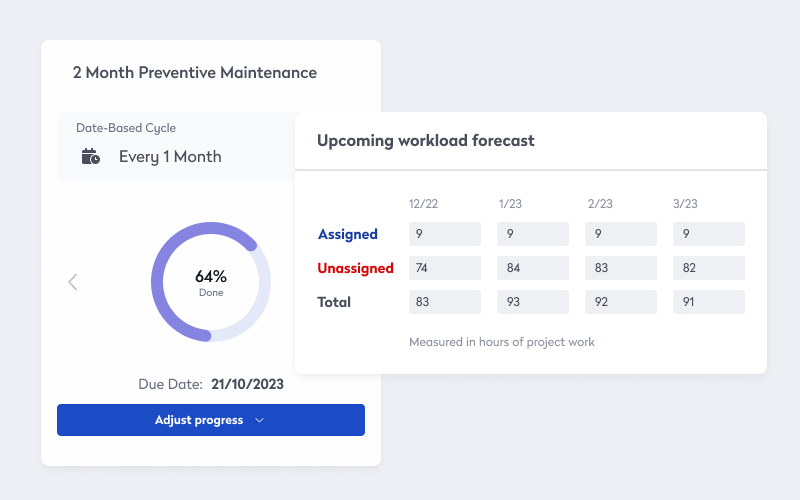

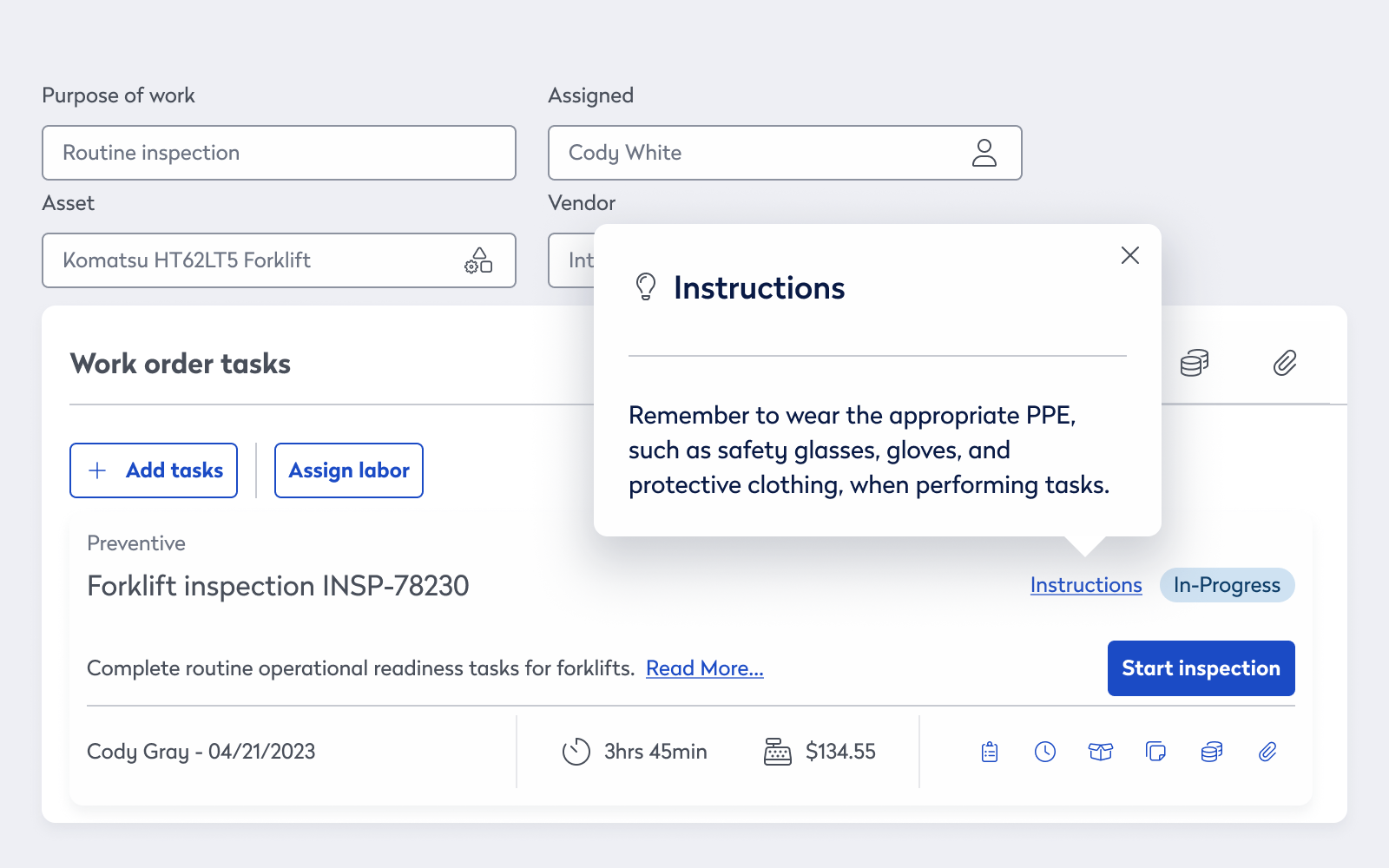

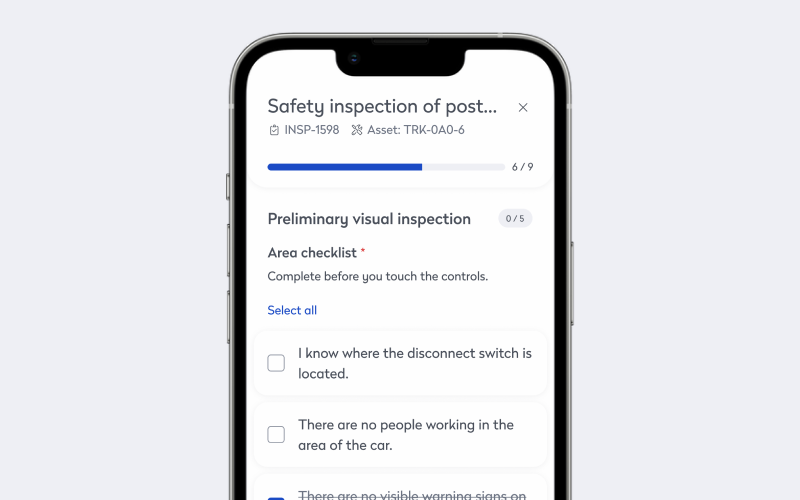

Optimize asset performance and ensure compliance with Eptura. Track every aspect of your assets, from machinery to infrastructure, and get detailed reports on budget allocation. Real-time monitoring keeps you informed, allowing proactive decision-making.

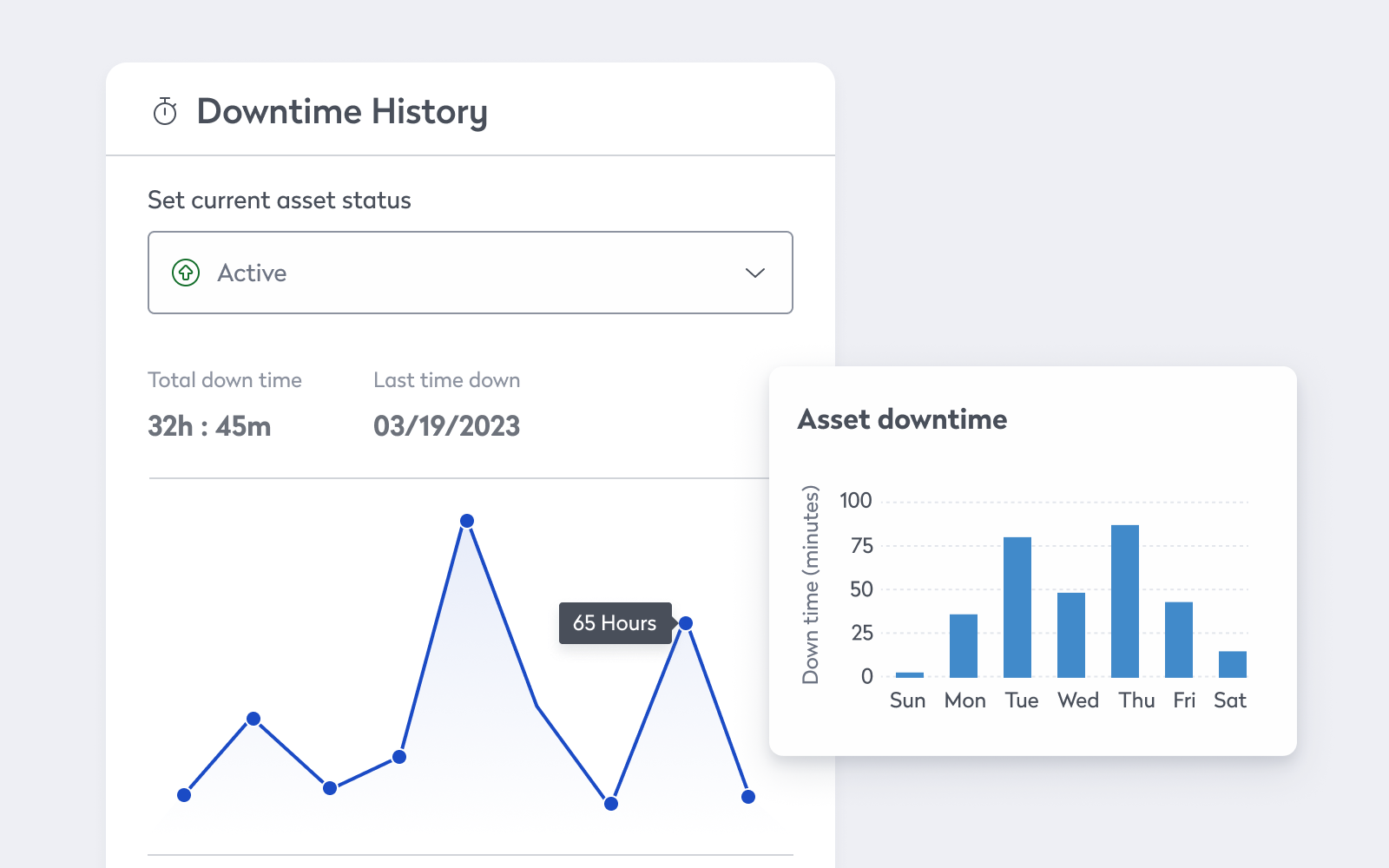

Every minute counts in manufacturing, where unscheduled downtime can translate to hundreds of thousands of dollars lost. Eptura minimizes downtime, maximizes efficiency, and fuels sustainable growth for your business with workplace and asset management software solutions.