A technician arrives at your manufacturing facility in Toledo to fix a recurring pump failure. They replace the worn bearing, close the work order as “complete,” and move on to the next call. Three weeks later, the same pump fails again. Your maintenance manager reviews the history and finds six work orders over eight months, each marked complete, but none explaining why the bearing keeps failing or identifying the root cause.

The team might be completing work orders, but critical context disappears into the gap between field execution and data systems in field services. The result is reactive cycles that drain budgets, frustrate technicians, and prevent your team from identifying systemic reliability issues before they cascade across multiple sites and field service territories.

Key takeaways

- When technicians leave the shop with complete equipment context, parts inventory visibility, and access to previous work orders, they arrive prepared for first-time fixes rather than discovering missing information on-site that requires return trips

- Technicians who document findings, photos, and equipment readings immediately at the point of service capture significantly more detail than those relying on end-of-shift memory. Delayed documentation loses the specifics that reliability engineers need for pattern analysis

- Moving beyond “fixed” or “replaced part” to document observed symptoms, root causes, environmental factors, and follow-up recommendations enables reliability teams to identify systemic issues affecting multiple locations and prevent future failures

When your technicians develop consistent habits around routing efficiency, real-time documentation, and thorough problem resolution, you build the data foundation needed to prevent failures rather than just responding to them.

Why work order data quality determines your maintenance maturity

When technicians document work orders without understanding how reliability engineers will analyze that data months later, they inadvertently create blind spots that prevent portfolio-wide and field service-level pattern recognition and proactive failure prevention.

“It’s critical that those teams understand the upstream and downstream impacts of what they are doing because a lot of times we will see certain functions or pieces of the process doing things a certain way, not recognizing that what they are doing may have a negative impact on something downstream, ” explains Erik Zink, VP, Corporate Development and Strategy and Chief of Staff at Eptura, in the Asset Champion podcast episode “Smart Somewhere: Enhancing Data Management across the Facility Asset Lifecycle.”

Building the three-habit framework: Route, record, resolve

Transforming work order execution from task completion to data generation requires three interconnected habits that work together to improve both immediate service and long-term reliability.

How to create a data culture that prepares technicians even before they leave the shop

Traditional field service work order routing sends technicians to sites with job numbers and basic descriptions. They arrive, assess the situation, and discover they need parts from the warehouse 40 minutes away or manufacturer documentation they can’t access in the field. Now you’re scheduling callbacks, coordinating parts delivery, and explaining delays to stakeholders while other priorities pile up.

Modern asset management platforms eliminate these delays by delivering comprehensive equipment context before technicians leave the shop.

A unified platform provides instant access to:

- Complete asset histories: Past failures, repair records, and maintenance patterns across your entire portfolio and field service regions

- Parent-child asset relationships: Component dependencies showing how systems, sub-systems, and parts connect

- Manufacturer specifications: Installation guides, operating manuals, and technical documentation

- Parts inventory status: Real-time visibility into stock levels across multiple warehouses

- Previous work orders: Detailed records from past service calls on the same equipment

For example, your technician routes to a chiller maintenance call at your Nashville office tower. Their mobile device shows the unit’s complete service history, including three compressor replacements in the past 18 months, and a pattern of refrigerant leaks traced to a specific valve assembly.

The system also displays the parent asset, the chiller unit, and all child components, including the compressor, evaporator, condenser, controls, confirming the replacement valve is in stock at your regional warehouse and providing the manufacturer’s installation guide.

So, they stop at the warehouse, complete the repair in one visit, and document the valve replacement with photos showing proper orientation—preventing future technicians from repeating the same installation error.

The routing intelligence matters more as portfolios expand geographically. When your technicians service facilities across multiple states, time spent driving between locations becomes a significant operational cost. Field service organizations waste significant technician time on travel, waiting, and coordination that could be eliminated through better pre-visit planning and resource optimization.

How to help technicians capture complete work order information in the field

The gap between completing work and documenting it creates two expensive problems. First, critical details fade from memory. Technicians who wait until end-of-shift to log notes capture significantly less detail than those documenting work immediately. Second, delayed documentation prevents real-time visibility for supervisors coordinating work across multiple sites.

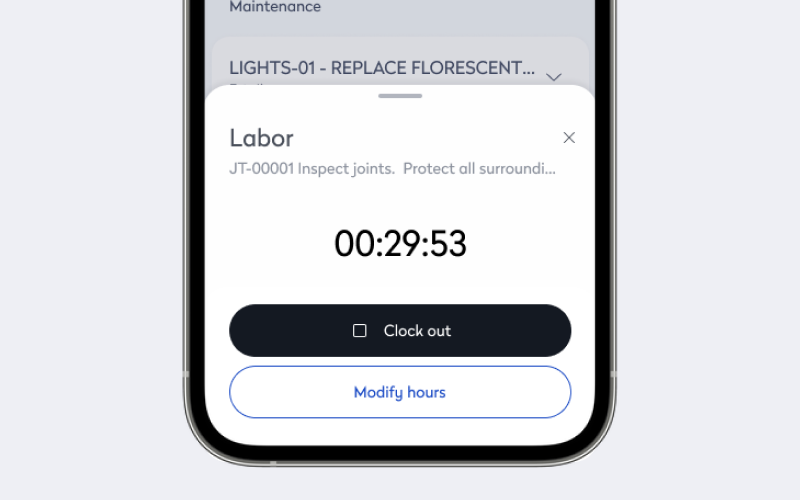

Real-time mobile documentation enables technicians to capture comprehensive work order data without disrupting service delivery.

The mobile-first platform supports:

- Photos and videos: Visual documentation of equipment conditions, repair procedures, and completed work

- Equipment readings: Temperature measurements, pressure levels, vibration data, and performance metrics

- Part numbers and quantities: Immediate logging of materials used during service calls

- Time stamps: Automatic recording of arrival, diagnosis, repair, and completion times

- Detailed condition notes: Rich text descriptions of findings, observations, and recommendations

- Automatic synchronization: All data syncs when connectivity returns for technicians working in areas with unreliable signals

The practical difference shows up in reliability analysis. Your reliability engineer reviews bearing failures across six manufacturing facilities to identify common causes. Sites using real-time mobile capture provide photos showing bearing collapse patterns, temperature measurements taken during operation, and detailed notes about unusual vibrations noticed weeks before failure. Sites relying on delayed manual entry offer generic descriptions like “bearing failed” with no supporting detail. The engineer can recommend targeted interventions for facilities with documented patterns but remains reactive at sites with incomplete data.

Offline functionality is particularly critical for facilities teams managing distributed portfolios. Technicians servicing remote assets like telecommunications towers, utility substations, and pipeline infrastructure operate in environments where connectivity fails regularly.

True offline capability means they can complete work orders, capture photos, log parts usage, and document findings without any signal—everything synchronizes automatically when connection returns, maintaining unbroken data chains across your portfolio.

What technicians should document beyond “fixed” or “replaced part

Surface-level work order notes like “fixed,” “replaced part,” or “completed maintenance” provide no intelligence for reliability teams analyzing failure patterns. Your maintenance manager reviews work orders for a problematic boiler and sees 12 visits over six months. Each lists repairs performed, but none explain the underlying condition causing repeated failures.

Effective field reporting requires technicians to communicate what they found, not just what they did.

Coach technicians to report what they found — not just the task they completed

Ask your technicians to begin every work order by documenting the symptoms they observed on arrival — the warning signs that showed something was wrong. A bearing might produce unusual grinding noise before failure, or a pump might develop abnormal vibration patterns. Temperature spikes, fluid leaks, or gradual performance degradation all signal developing problems before catastrophic failure occurs.

Direct your team to document root cause findings that explain what actually failed and why. A bearing doesn’t simply collapse — it fails because lubricant becomes contaminated with metal particles or ran dry due to inadequate maintenance intervals. Seals degrade from chemical exposure to cleaning agents that weren’t specified for that application. Control boards fail from power surges when your facility’s electrical protection proves insufficient.

Have technicians record environmental factors that may have contributed to the failure. Equipment operating in 105°F ambient temperatures fails faster than identical units in climate-controlled spaces. High humidity accelerates corrosion. Inadequate ventilation allows heat buildup beyond design limits. Operational stress from running equipment at maximum capacity without scheduled downtime compounds mechanical wear.

Encourage technicians to capture corrective actions and preventive recommendations

Tell your technicians to go beyond listing the replaced part and record all corrective actions they performed.

For example, did they:

- Clean contaminated lubricant from the components?

- Adjust the overall alignment, including surrounding parts?

- Upgrade to a higher‑grade seal material?

These details matter when determining whether the fix addresses underlying conditions or simply swaps out a failed part.

Ask them to include follow‑up recommendations that help prevent recurrence. They might recommend the facilities team assess room HVAC before heat stress causes more failures. They might suggest engineering evaluate whether preventive maintenance intervals match actual operating conditions. They could flag vendor quality issues that require procurement review.

For example, consider a field service technician servicing a motor failure at one of your Texas distribution centers. Instead of noting “replaced motor,” the technician documents: “Motor bearing failure caused by inadequate cooling—equipment room temperature measured at 105°F, ventilation system operating below design capacity. Installed replacement motor and recommended facilities team assess room HVAC before other motors fail from the same heat stress.”

Strong reporting enables your reliability team to identify that inadequate cooling affects multiple assets in that location, justifying an HVAC upgrade that prevents future failures rather than continuously replacing motors.

The technician didn’t resolve the systemic issue, but their detailed reporting made the pattern visible to the people who could.

Transform work orders into reliability intelligence

When field teams develop consistent habits around preparation, thorough documentation, and detailed reporting, they generate the data foundation needed to shift from reactive maintenance to preventing failures across your portfolio.

A global aerospace and defense manufacturer achieved results after implementing mobile-first maintenance management: 25% improvement in technician productivity, 20% reduction in equipment downtime, and 15% increase in asset lifespan.

Discover how technician productivity improved by 25%.