For facility management and maintenance professionals, the real value of technology lies in its ability to empower teams. Modern solutions don’t replace the invaluable expertise of your technicians. They help you amplify it, enabling technicians to leverage their years of experience and deliver maximum value to the overall organization.

Visual inspections, a critical component of proactive maintenance, are a strong example of how the right tools help you support your facility teams, allowing them to do what they do best.

Key takeaways

- Visual Inspections are critical for early detection, allowing you to identify potential issues high on the P-F curve and prevent costly failures before they occur

- Maintenance departments can overcome traditional inconsistencies by implementing standardized digital checklists and clear procedures, ensuring every inspection is thorough and dependable

- By leveraging modern tools to capture rich inspection data, teams can turn routine checks into actionable insights that inform strategic maintenance planning and optimize asset performance

When inspections move from paper to digital, they stop being a checkbox exercise and start becoming a strategic advantage, helping you catch issues early, standardize processes, and turn data into decisions.

What are visual inspections and why are they important for proactive maintenance?

While the term “visual” suggests it’s only about what technicians can see, experienced maintenance professionals use more than just their eyes. They might listen for unusual noises, feel for excessive vibrations or heat, or even try to detect the faint scent of a leak. It’s this comprehensive approach that helps them identify problems high up on the P-F curve, where the early-warning signs of failure start to appear.

By catching issues when they are small, facilities can avoid costly repairs, minimize downtime, extend asset life cycles, and significantly enhance safety for occupants and staff.

What are the common challenges with visual inspections, and how can maintenance teams overcome them?

The common challenges often come from manual processes and a lack of integrated digital tools, leading to inconsistencies and missed opportunities for proactive maintenance.

Maintenance teams can find themselves struggling with:

- Pervasive inconsistency: Without standardized procedures, inspections can vary in quality. What one experienced technician knows to look for, another might miss

- Limited documentation: Paper-based checklists or informal notes are prone to loss, too time-consuming to analyze, and offer limited historical context it difficult to track trends or demonstrate compliance

- Scheduling gaps: Manual scheduling can lead to missed inspections, creating opportunities for issues to develop unnoticed, leading to unexpected downtime or more costly repairs

- Delayed action: Identifying an issue is only the first step. If reporting and work order generation demand too much time, critical problems can be delayed, impacting resolution times and potentially escalating minor issues into major failures

All these challenges highlight a clear need for a more structured, consistent, and data-driven approach. Modern facility management solutions offer the framework to overcome these obstacles, transforming visual inspections into a reliable and efficient component of your overall maintenance strategy.

By integrating advanced technology, these tools empower your technicians, streamline operations, and provide the data-driven insights you need to move beyond reactive maintenance. They offer a comprehensive framework that not only supports your visual inspection efforts but fundamentally elevates them, ensuring greater accuracy, consistency, and a more proactive approach to asset management.

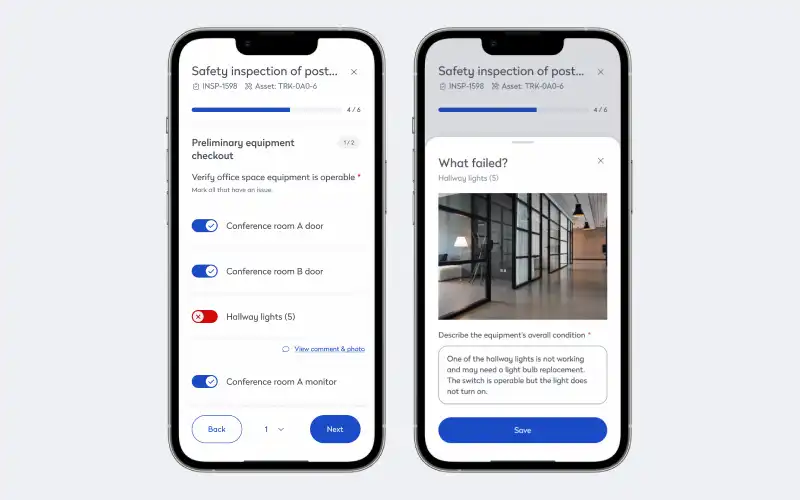

Digital checklists and standardization: Ensuring consistency and precision

With a modern facility management solution, you gain access to customizable, digital checklists directly on mobile devices, and you can tailor checklists to specific assets or locations, prompting checks for gaskets, switches, or floor conditions in the correct sequence.

Standardization ensures every visual inspection is thorough and consistent, regardless of the technician’s experience level, elevating the quality of your maintenance program and providing a reliable baseline for asset health.

Manufacturing: Precision visual inspections for asset life cycles

In a manufacturing environment, your technician inspecting a critical production line machine can use a digital checklist to methodically verify lubrication levels, belt tension, and sensor readings, ensuring all critical points are covered consistently across shifts, significantly reducing the risk of unexpected downtime and maintaining optimal operational efficiency.

They’re not just checking boxes. Instead, they’re building a reliable history of asset health that informs future maintenance decisions, ultimately extending the life cycles of your valuable equipment and streamlining your overall facility management.

Streamlining with intelligent scheduling and automation: Optimizing time and resources

Your facility management solution eliminates the manual tracking and guesswork often associated with inspection scheduling. With automated scheduling, recurring inspection tasks, and configurable reminders, you can ensure inspections are never missed. The system automatically assigns inspections based on asset type, location, or required frequency, intelligently optimizing technician routes and workload.

Government facilities: Proactive maintenance for public infrastructure

For government facilities, managing a vast portfolio of diverse assets, from municipal buildings to public parks, presents unique challenges. Your FM team can schedule quarterly HVAC inspections across a campus of administrative buildings, with the facility management solution automatically assigning tasks and sending reminders to the relevant technicians, ensuring critical infrastructure is maintained, supporting public services and extending the life cycles of taxpayer-funded assets, all while demonstrating responsible resource management.

Real-time data capture and instant work order generation: From observation to action

As soon as the team finds an issue, they can generate a work order on the spot. The seamless workflow drastically reduces the time between identifying a problem and initiating its resolution, preventing issues from “slipping through the cracks” and significantly improving your team’s responsiveness.

Hospitality: Ensuring guest comfort and operational excellence

For the hospitality sector, guest satisfaction is directly tied to the quality and functionality of the environment. During a routine room inspection, a hotel engineer identifies a faulty light fixture. They can log the issue, take a picture, and generate a maintenance request instantly. This ensures guest comfort and safety are maintained without delay, reflecting positively on your establishment’s service standards and preventing minor inconveniences from escalating into negative guest experiences.

Reducing errors and risks with comprehensive data: Informed decision-making

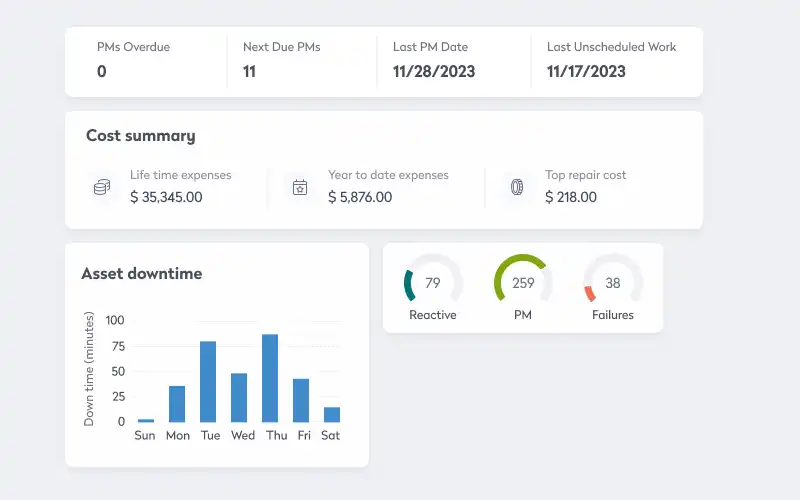

Your facility management solution provides a centralized database for all inspection data, historical records, and audit trails. Every inspection, every finding, and every resolution is logged and easily retrievable.

Rich historical data allows your FM teams to identify recurring problems, track asset performance over time, and support compliance requirements with ease. By understanding patterns and trends, you can move from reactive fixes to more predictive maintenance strategies, significantly reducing operational risks and improving safety across your facilities. This data-driven approach is a cornerstone of effective facility management.

Transportation hubs: Enhancing safety and reliability for critical infrastructure

In busy transportation hubs, the safety and continuous operation of critical assets like escalators, elevators, and baggage systems are non-negotiable. Analyzing historical inspection data helps you predict component wear and potential failure points, allowing for proactive replacements and preventing service disruptions or safety hazards for thousands of daily commuters. Strategic use of data ensures reliability and supports the smooth flow of operations.

Actionable reporting and Strategic next steps: Optimizing maintenance strategies

Beyond streamlining capture data, modern facility management solutions help you transform it into actionable intelligence through customizable dashboards, analytics tools, and robust reporting capabilities.

As an FM manager, you can generate insightful reports on inspection completion rates, common issues by asset type, technician performance, and more. The data informs your strategic decisions, optimizes maintenance schedules, helps justify budget requests, and clearly demonstrates the ROI of your proactive maintenance efforts.

Commercial real estate: Driving efficiency and tenant satisfaction

For commercial real estate property managers, optimizing operational costs and ensuring tenant satisfaction are key. You can use inspection reports to identify common HVAC issues across your portfolio, leading to a strategic upgrade plan that reduces energy costs and tenant complaints. Data-driven insight allows you to make capital expenditure decisions that yield measurable returns and enhance property value.

Sample visual inspection workflow with modern FM software

By following this streamlined approach, you can transform routine inspections into a powerful, data-driven component of your overall asset management strategy.

- Schedule and assign: Your facility management solution automatically schedules a recurring inspection for a specific asset like a boiler in a manufacturing plant and assigns it to a qualified technician. Reminders are sent automatically

- Conduct inspection: The technician accesses the digital checklist on their mobile device. They follow the step-by-step prompts, marking items as pass/fail, adding notes, and capturing photos or videos of any observations

- Identify and report: Upon finding a minor issue (e.g., a loose bolt) or a more significant problem (e.g., a small leak), the technician immediately creates a new work order directly from the inspection screen. The system automatically links it to the asset and inspection record

- Resolve and document: The work order is routed to the appropriate team. Once completed, the resolution details, parts used, and labor hours are logged in the facility management solution, creating a comprehensive history

- Analyze and optimize: FM managers review dashboards and reports to track inspection compliance, identify trends in asset performance, and refine maintenance strategies for continuous improvement

From proactive scheduling and guided execution to immediate issue reporting and strategic analysis, your team is equipped with the tools to work smarter, not harder.

Optimize maintenance with modern visual inspections

By supporting visual inspections with modern facility inspection tools and a robust facility management solution, you help technicians leverage their invaluable expertise more effectively, moving your organization beyond reactive fixes to truly proactive, data-driven maintenance. This approach streamlines operations, helps reduce errors and risks, and ultimately supports the longevity of your assets and the efficiency of your budget.