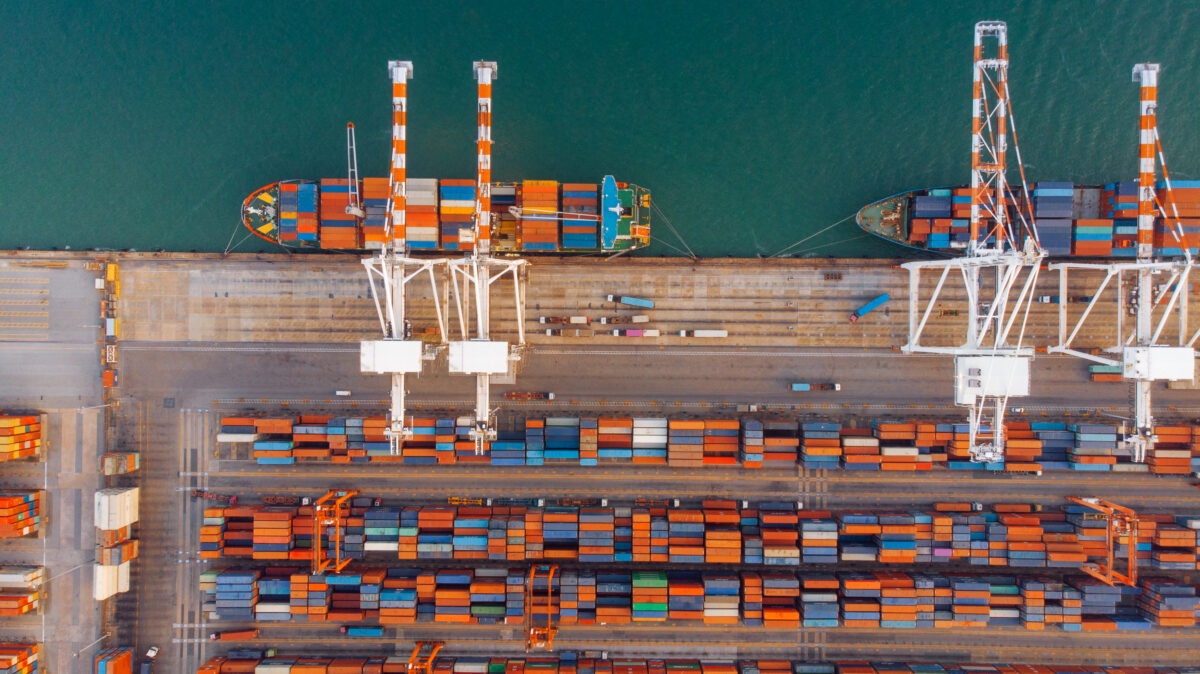

The question “where is it?” costs logistics and fleet operations billions of dollars every year. A trailer that should be at the depot is somewhere in the yard. Equipment scheduled for deployment sits idle at the wrong location. Fleet vehicles are missing maintenance windows because nobody knows their actual status or where they’ve been.

In fact, unplanned downtime costs industrial manufacturers an estimated $50 billion annually, with logistics operations facing similar pressure as they manage increasingly complex fleets across multiple transportation modes.

Unified asset visibility transforms these operational challenges into competitive advantages by connecting scattered data into actionable intelligence that drives better decisions, reduces waste, and ensures assets work where and when they’re needed most.

Key takeaways

- Asset visibility gaps create cascading costs beyond search time. Organizations lose productivity through idle equipment, administrative overhead consuming 1.8 hours daily, and customer service failures that damage revenue

- Modern platforms deliver interconnected capabilities including real-time location tracking, predictive maintenance, mobile accessibility, and unified data that eliminates spreadsheet-based silos

- Organizations achieve measurable transformation, as demonstrated by Maritime Developments’ 50% reduction in administrative work and 8+ hours saved per technician weekly across 300+ globally distributed assets

What happens when you lose track of your assets

Organizations operating without comprehensive real-time tracking across their logistics operations face quantifiable costs that compound across every operational metric.

End-to-end supply chain visibility through real-time asset tracking can reduce logistics costs by up to 15% while improving customer satisfaction through more reliable delivery windows, according to McKinsey.

The inverse is equally true. Maintaining blind spots drives costs higher.

Equipment sitting idle or misallocated generates zero return while consuming capital, insurance premiums, and storage space. Organizations frequently discover they’re renting or purchasing replacement equipment while identical assets sit unused elsewhere.

Administrative overhead drains resources as teams spend hours searching for equipment and reconciling conflicting records. Knowledge workers waste 1.8 hours every day searching for information that should have been documented and accessible, according to McKinsey.

Meanwhile, customer service failures driven by asset visibility gaps undermine long-term revenue and competitive position. Late deliveries, service disruptions, and unreliable performance damage customer relationships in ways that extend beyond individual transaction costs.

Asset visibility maturity assessment: Calculate your hidden costs

Most logistics operations believe they have “good enough” visibility—until they measure what those blind spots cost. Take the assessment to identify gaps in your current approach and see where unified asset visibility could deliver measurable ROI.

Note that every logistics operation faces unique challenges based on industry, scale, geography, and operational maturity. The statistics and cost estimates below represent industry averages and benchmark data from multiple sources. Your actual costs and potential savings may vary significantly based on your specific situation. Use this assessment as a general framework to identify areas for deeper investigation within your own operations.

Rate each statement on a scale of 0-2:

0 = Never/Not true

1 = Sometimes/Partially true

2 = Often/Completely true

Operational efficiency

Cost and resource impact

Decision-making and visibility

Integration and scalability

Score your results

0-8 Points: Solid foundation

You have strong visibility practices in place. Focus on optimization opportunities like predictive maintenance or AI-powered analytics to extract incremental gains. According to industry research, even organizations with mature systems can achieve 15-25% reductions in logistics costs through targeted improvements.

9-16 Points: Significant opportunity

Your current approach has notable gaps that create hidden costs. Companies at this stage typically see 15% lower logistics costs and 35% better inventory management after implementing unified asset visibility platforms. Industry data shows only 43% of organizations have solid visibility into tier 1 supplier performance. You’re likely among the majority that could benefit from better systems.

17-24 Points: Critical gaps

Asset visibility blind spots are significantly impacting your operations. Research indicates supply chain disruptions cost companies approximately 8% of annual revenue, and your manual processes are likely contributing to this figure. Modern platforms can reduce these costs while improving service levels by up to 65%.

25-32 Points: Urgent need

Your reliance on manual tracking creates serious operational risk. With U.S. business logistics costs reaching $2.3 trillion (8.7% of GDP), even small efficiency improvements deliver substantial returns. Leading companies report 25-35% reductions in inventory costs and up to $8 in ROI for every dollar invested in AI-powered visibility solutions.

The real costs of poor asset visibility

If you scored above 9, consider these costs:

- Manual tracking time: Research from Gartner shows that manual inventory processes consume hundreds of man-hours per audit, with one documented case requiring 1,100 days out of 1,900 total audit days just for reconciliation efforts. Deloitte research estimates that intelligent tracking technologies can save 75-95% of time on routine tracking tasks, potentially recovering 2 million hours annually for large enterprises

- Reactive maintenance: Unplanned downtime costs industrial manufacturers an estimated $50 billion annually. Preventive maintenance enabled by real-time asset visibility can significantly reduce this burden

- Logistics inefficiency: Companies implementing AI-powered route optimization report 10-15% reductions in fuel and dwell time, while overall logistics costs can drop by 15-25% with proper visibility systems

- Inventory management: Poor asset visibility leads to 25-35% higher inventory carrying costs due to safety stock buffers, duplicate purchases, and misplaced equipment

- Delivery performance: End-to-end supply chain visibility through real-time asset tracking can reduce logistics costs by up to 15% while improving customer satisfaction through more reliable delivery windows

Even preventing a single emergency repair, eliminating one delayed deployment per month, or reducing manual tracking time by a few hours per week can justify investment in modern asset visibility platforms.

The platform features that matter most for asset visibility in logistics

When evaluating asset visibility solutions, prioritize capabilities that deliver measurable operational improvements rather than focusing solely on feature lists. Effective visibility systems create value through how capabilities work together rather than through isolated features.

Access your data anywhere with mobile-first design

Field teams access complete asset information and log updates from anywhere—offices, yards, warehouses, or remote job sites. Work continues without interruption even when network connectivity drops, with updates synchronizing automatically when connections restore.

For example, a technician inspecting trailers in a far corner of the yard can document issues immediately, even without cell service. When they return to the office, all inspection data syncs automatically, triggering work orders for any problems found. Operations never wait for connectivity to perform critical tasks.

Maintain one source of truth with centralized asset registry

Every asset has comprehensive records, including specifications, configurations, maintenance histories, warranty information, contracts, and parts inventories, stored in a single location. Version control problems and data inconsistencies disappear.

When a dispatcher needs to deploy a specific asset, they see current location, maintenance status, and availability instantly rather than calling three different people to piece together information. Better decisions and seamless coordination follow when everyone accesses the same data.

Find equipment instantly with interactive location mapping

Visual maps with 2D floorplan integration pinpoint exact asset locations within facilities or yards. Instead of walking the entire north yard to find one specific trailer, operations teams click a map and navigate directly to the asset’s precise location. Search time drops from 30 minutes to 30 seconds.

For large operations managing hundreds of assets across multiple locations, this spatial intelligence transforms deployment planning from guesswork into precision.

Leverage existing systems with smooth integrations

Open APIs and modular design connect asset visibility platforms with ERP systems, HR platforms, telematics systems, and IoT sensors. When a maintenance work order closes in the asset system, it automatically updates inventory levels in the ERP and triggers parts reordering if stock falls below thresholds.

Data flows seamlessly across platforms without duplicate entry, and existing technology investments enhance rather than get replaced by new systems. Vendor lock-in becomes a non-issue.

Scale as your operations grow

Cloud-based architecture maintains consistent performance whether managing 300 assets or tens of thousands. Organizations start with one location and expand across regions without performance degradation or system slowdowns.

The computational power and storage capacity scale automatically, eliminating the need for complex on-premises infrastructure or capacity planning exercises every time operations expand.

Protect your data with enterprise-grade security

Role-based access controls, audit logging, data encryption, and redundant architectures prevent unauthorized access while maintaining uptime. A maintenance supervisor sees asset histories and work orders but can’t access financial data.

Executives view cost analytics but can’t modify technical specifications. Every action creates an audit trail, and data remains encrypted both in transit and at rest.

Eptura in action: How MDL saved 8+ hours per technician every week

Maritime Developments (MDL), managing complex offshore operations across global locations, needed to modernize how they tracked and maintained their critical assets. Asset data was scattered across spreadsheets, emails, and word documents—or relied entirely on team members’ memories. MDL lacked the centralized visibility needed to manage their growing fleet effectively and ensure consistent maintenance standards.

The offshore services company faced significant operational challenges. Technicians spent hours manually logging maintenance data after completing projects offshore, creating delays between work completion and actionable reporting.

MDL implemented Eptura Asset to create a unified digital system for asset management and maintenance workflows.

The company digitized preventive maintenance processes, creating a centralized repository where anyone could check the status, condition, and history of each asset. They enabled mobile maintenance logging so offshore technicians could document work in real time rather than hours later.

The system now tracks 300+ assets with 1,000+ work orders managed monthly, providing complete visibility across MDL’s global operations.

After implementation, MDL achieved:

- 50% reduction in administrative work, freeing technicians to focus on high-value technical tasks

- 8+ hours saved per technician per week through automated maintenance logging and centralized data access

- Decreased maintenance costs through better planning and earlier problem detection

- Smoother workflows with fewer disruptions as teams access complete information in real time

- Greater visibility of asset performance enabling data-driven operational decisions

The transformation enabled MDL to manage their complex, globally distributed assets with consistent standards and real-time reporting, supporting reliable offshore operations while controlling costs.

Learn how they digitized maintenance workflows and achieved measurable ROI in the complete MDL success story.