Work orders are the heart of your overall maintenance workflow. They’re the tool that ensures all the activity related to asset maintenance gets done. They can be orders that cue expected preventive maintenance services or more immediate corrective requests for assets such as manufacturing equipment or fleet vehicles.

Done right, maintenance work orders optimize the movement of projects through the critical stages of operation and empower team members to perform their jobs efficiently and with greater accuracy. However, when part of an enterprise asset management (EAM) platform, work order software also captures information that can be used to continually improve your performance and support business objectives across the enterprise.

Organizations can save time and boost profitability by creating better work order processes that make sense for the asset manager as well as the technical teams that follow through on the tasks. This requires improving the process at all four stages in the life of a work order: initiation, schedule, work, and verification.

The role of work orders in asset maintenance

Work orders are the operational backbone of maintenance teams. They standardize the process for both scheduled maintenance (e.g., routine inspections or servicing) and unscheduled tasks, such as repairs. For large enterprises, where operations span multiple locations, work orders must be designed to accommodate complex workflows that often involve various departments, geographical areas, and asset types.

In this context, Enterprise Asset Management (EAM) systems play an essential role. An EAM platform centralizes the entire maintenance process, automating work orders and aligning them with asset lifecycle management. By integrating service requests into work order processes, companies can ensure that maintenance tasks are logged, executed, and tracked in a way that promotes efficiency and data-driven decision-making.

Why optimizing work order processes is critical for multi-location enterprises

Large enterprises face unique challenges when it comes to managing maintenance across different facilities and geographical locations. A decentralized work order process may lead to:

- Inefficiencies in how work orders are initiated, scheduled, and executed.

- Lack of visibility into asset conditions and maintenance needs across the organization.

- Delays in responding to critical repairs, increasing downtime and potential loss of revenue.

By optimizing work order processes, multi-location organizations can streamline maintenance, improve communication between departments, and reduce operational downtime. Additionally, it ensures that the right resources are allocated to the right tasks, reducing unnecessary expenditures.

Stages of work order optimization

Work orders go through four main stages: initiation, scheduling, execution, and verification.

1. Initiation: Service requests and automation

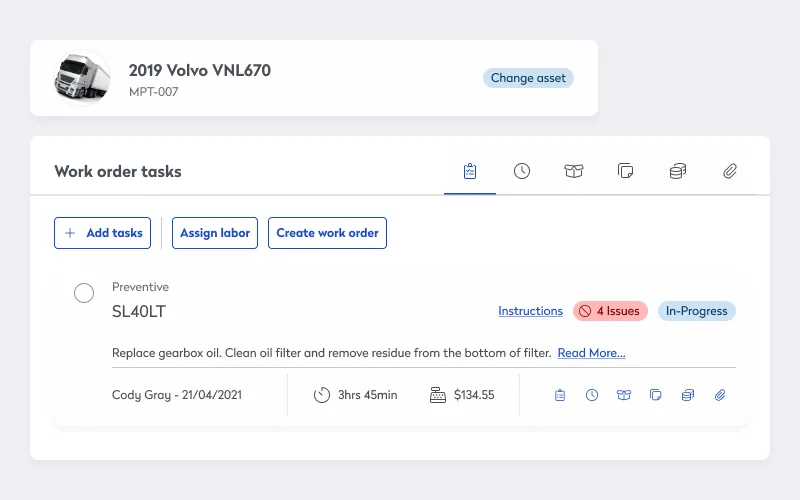

Work orders are created automatically or when an associate makes a request for service on a particular asset. If a task is planned based on a trigger — such as a period of time passed or a certain number of production cycles — the EAM platform will deliver a notification that initiates the work order. This automatically compiles the details of the job and routes to the appropriate team for action. For instance, in a multi-location manufacturing company, a technician noticing a fault in a piece of equipment in one location should be able to submit a service request through a mobile app. The EAM system then automatically generates a work order and assigns the task based on urgency and resource availability.

The more information that is included in a work order request, the more likely the task will be completed quickly and correctly. For example, advanced EAM software will allow you to add essential information specific to each request, including required parts and materials, the current availability of parts and materials, safety, and plant or equipment shutdown requirements.

Ways to improve the initiation stage of the work order process include:

- Add the right information to the work order. Most work orders include general information about the work request, such as location of the asset, priority, and work status. Digital solutions give you the option to add more fields to further flesh out the information according to your specific business needs. For example, you can include digital manuals, instructions and checklists, and complete repair and maintenance histories.

- Use templates and standard operating procedures. In EAM work order systems, you can create checklist templates and protocols for work in facilities as well as in the field. This gives you a standardization process that helps reduce errors and save on administrative time.

- Use work orders for every task, no matter how small. If you’re not currently using work orders for small tasks, like changing light bulbs on the shop floor, that’s a great opportunity to level up your work order process. Small tasks can add up, and you should track them to make sure your productivity metrics are accurate. Plus, every asset-related task must contribute to a system of record that supports preventive maintenance, creates an accurate count for inventory tracking, and helps troubleshoot future issues.

2. Scheduling: Resource allocation and prioritization

Once you create them, assign work orders to staff technicians, contractors, or vendors based on their level skill, expertise, and availability. Schedule work orders based on a set deadline, planned maintenance triggers, or dedicated blocks of time within your overall asset management strategy.

An intelligent EAM software solution will include the ability to view the schedules of each technician, which offers asset managers a high-level snapshot of maintenance activities. As a result, you can avoid problems such as double booking, downtime when a technician is off duty, or inefficient sequencing of maintenance tasks.

With streamlined scheduling functionality you can make sure expectations are clear and that technicians know when and what they are expected to do. Also, work order management software includes time-saving features that allow workers to review work histories, confirm task completion, and document their job notes.

Ways to improve the scheduling stage of the work order process include:

- Prioritize jobs. For the best efficiency, you should prioritize active work orders each day, or sometimes on an hourly basis. Determine priority based on the criticality of each service (for example, emergency versus routine repairs), or by the criticality of the asset. You can program software systems to define levels of criticality for each type of repair or asset. This makes scheduling that much easier, allowing you to gauge the priority level of each assignment. As a result, you can ensure that the most important projects, including those that impact safety, will be given priority over non-essential jobs, such as routine maintenance requests.

- Schedule and assign tasks to the right workers. Assigning work orders is easier when you have clear insight into each technician’s schedule and their level of expertise. When you know where they are assigned, the priority levels of their jobs, the expected time allotted to each job, and when they have downtime, you can more effectively assign new work orders.

- Set a timeline for each project. Your work order management software will allow you to set standards for projects, including how long each task should take from start to finish. This keeps everyone informed and accountable, so nothing falls through the cracks. It’s also important to review your data for scheduled project time versus actual time in order to continually refine your scheduling strategy.

- Program future work order assignments. Systems that don’t allow for automated scheduling of upcoming and recurring work assignments will put asset managers at a serious disadvantage, because these future tasks can be too easily missed. When you pre-schedule critical tasks with automated notifications, you reduce the risk of downtime and asset failure.

3. Execution: Streamlining the work process

While executing maintenance projects, technicians need to record everything from routine procedures completed to additional notes on the health of the asset. The more information they document, the easier it is to manage future maintenance and repairs. For an enterprise, the work order data also informs decisions regarding budgets, forecasts, and big-picture operational strategies.

Ways to improve the execution stage of the work order process include:

- Track work orders. When asset managers deploy work orders in advanced EAM systems, they gain the ability to track tasks in real time — from submission through completion. In this way, you can keep your finger on the pulse of each day’s workload, foresee potential problems, and track critical variables to adjust as needed. Customized workflows, alerts, and approval levels keep teams updated on performance as work is completed.

- Use mobile devices to manage work orders. Accessing and tracking work orders through mobile devices opens a new world of opportunity, especially for field workers. They no longer have to report to a central location, such as an office, to see where they need to be and what to do. With digital work order management, supervisors and technicians can create, modify, or update work orders directly from their phones or tablets. The most advanced systems also provide bar-code capabilities that allow users to capture information by snapping a photo of a bar code on an asset or inventory item with their device’s camera.

- Leverage data. Work order management within EAM systems provides real-time insight into work in progress from one central dashboard. Dashboards give project managers and owners immediate insight into the status of each project and reports on everything from productivity levels to inventory requirements to costs. Modern asset management relies on capturing the right data and putting it into action.

4. Verification: Ensuring completion and quality control

At the verification stage of maintenance, managers, team leaders, or other stakeholders can analyze projects on several levels, from job performance to cost management. Although some projects will be simple to assess, others might have many variables that call for an advanced review. Either way, when all the data related to every asset lives in one location, the asset team will have one reliable source of truth.

A digital solution adds advanced capabilities to put work orders in context across the enterprise. For example, an EAM platform will ensure inventory levels are automatically updated when work orders are closed. They also automatically populate business intelligence reports to provide accurate forecasting and improve strategic planning.

Two ways to improve the verification stage of the work order process include:

- Close and file each work order. Upon completion of each work order, managers should ensure the work meets expectations, including compliance requirements. Then, if approval is part of the workflow, they should officially close the projects and file the documentation. This ensures an accurate end-to-end process for the entire work order.

- Keep regulations in mind. A properly organized work order log achieves a wide variety of benefits, including building an asset maintenance history and helping organizations meet regulatory obligations. For example, the Food and Drug Administration rule known as Title 21 Part 11 requires that manufacturers keep maintenance records that are both “human readable” and prepared in an electronic format that would be suitable for review by the agency. Your comprehensive work order strategy must be built to satisfy the regulations that pertain to your business.

Leveraging EAM software for multi-location enterprises

For multi-location enterprises, the complexity of managing work orders across different sites can be overwhelming without the right tools in place. EAM software offers an integrated approach to managing asset maintenance, providing visibility, automation, and analytics to streamline work order processes. The work order management capabilities offered by Eptura Asset have helped organizations around the world improve their asset management and realize a return on investment. If work orders are a critical part of your strategy, request a personalized demo of Eptura Asset and see how it can improve work orders for your organization.