Misaligned maintenance in manufacturing operations drains productivity and profitability. Simply adopting “good maintenance” isn’t enough, though. The solution is implementing the right mix of preventive and predictive triggers that match your equipment, operating conditions, and budget realities.

The most successful mid-market manufacturers don’t choose between preventive maintenance (PM) and predictive maintenance (PdM). They sequence both strategically, building preventive discipline first before introducing selective predictive capabilities where they deliver the highest ROI. With unplanned downtime costing Fortune Global 500 companies 11% of yearly turnover, organizations need a pragmatic, phased approach to maintenance modernization that allows them to apply lessons-learned while building on earlier successes.

Key takeaways

- Sequence PM before PdM for maximum impact: Master preventive maintenance fundamentals first, achieving higher compliance rates before introducing predictive capabilities. A sequenced approach creates the data foundation and team habits necessary for successful predictive maintenance scaling

- Use condition-based triggers strategically: Apply preventive maintenance to safety-critical systems and equipment with stable operating conditions, while reserving predictive maintenance for aging critical assets, high-downtime-cost equipment, and machinery with variable operating conditions

- Prove value through focused pilots: Leverage your maintenance management platform’s reporting tools to document reduced downtime costs, lower emergency repair expenses, and improved production throughput, building the business case for broader deployment

Every factory faces its own specific set of operational circumstances, but these principles can help you create a pragmatic, tailored roadmap for advancing reliability maturity.

What keeps manufacturing plants in reactive maintenance

Many mid-market manufacturing plants operate in a perpetual state of reactive maintenance despite leadership’s desire for more proactive approaches. Manufacturers expect input costs to increase by an average of 5.4% over the next year, while aging equipment and workforce challenges amplify operational pressures, according to the National Association of Manufacturers’ 2025 Manufacturing Outlook.

Manufacturing facilities now lose an average of 25 hours monthly to unplanned downtime, with the ABB Value of Reliability report finding that two-thirds of companies deal with unplanned downtime at least once a month, at a cost of $125,000 per hour. Mean time to repair has increased from 49 minutes to 81 minutes, driven largely by supply chain delays and a widening skills gap.

Shawn Morgal, vice president of facilities management and operations and maintenance at The Building People, explained the importance of trained technicians to overall success in a Asset Champion podcast episode.

“You could have the best facility manager overseeing any building in any location, but you really need to understand and appreciate that it’s the boots that are on the ground, the hands that are turning the wrenches, the staff that is keeping those facilities conditioned and clean and safe and accessible.”

Build preventive maintenance discipline first

Strong PM discipline creates the foundation you need for successful PdM implementation while delivering immediate reliability improvements. Organizations with mature preventive maintenance programs experience significantly reduced downtime and extended asset life cycles, according to Eptura’s 2025 Workplace Index. Deloitte research confirms those findings, showing predictive maintenance can reduce maintenance costs up to 25% and increase uptime by 10% to 20%.

Implementing and running a PM program is a multistep process that includes:

- Establishing consistent maintenance routes and frequencies: Work through your asset inventory systematically, beginning with equipment that supports critical production processes. A food processing plant might prioritize mixing equipment and packaging lines, while an automotive parts manufacturer focuses on stamping presses and welding robots. Document specific inspection points, required tools, and acceptance criteria that define proper preventive maintenance for each asset class

- Ranking assets using risk-based criticality: Consider multiple factors including replacement cost, production impact if failed, safety risks, environmental consequences, and current asset condition. The primary CNC machine on your production floor carries higher criticality than a backup unit, just as the main injection molding press demands more attention than auxiliary equipment.

- Creating standardized task libraries: Develop procedures organized by asset type and maintenance frequency. Standardized procedures ensure consistency regardless of which technician performs the work, while enabling accurate time estimates for scheduling and capacity planning. A plastics manufacturer managing multiple production lines can apply the same extrusion equipment checklist across machines, adjusting only for model-specific details

- Tracking compliance religiously: Treat PM compliance as a fundamental team performance metric that predicts future reliability. Your maintenance platform can show you exactly which planned tasks were completed on schedule and which require attention

In an episode of the Asset Champion podcast, Cameron Christensen, director of asset management for facilities operations at Princeton University, stressed the need to understand the relationship between strategy and technology when implementing new programs. While closely connected, they are also different.

“Technology is not the strategy. It’s an accelerator of strategy. It’s a very important piece of our strategy, but it’s not the strategy itself.”

Implement maintenance software to enable data-driven reliability

Once your preventive maintenance discipline reaches consistent compliance levels, you have the stability necessary to introduce predictive maintenance management.

Here, the key is leveraging technology to identify high-impact applications where condition-based triggers deliver clear advantages over time-based approaches.

Introduce predictive triggers with condition monitoring

Focus your predictive investments on assets where failures carry significant operational or financial consequences. Equipment supporting continuous production processes, assets with high repair or replacement costs, and machinery where failures create safety risks or environmental incidents justify the incremental cost of condition monitoring.

For a pharmaceutical manufacturer, this might mean critical tablet presses and coating equipment, while at a metal fabrication operation, it includes primary cutting and forming machines where failures halt entire production cells.

Vibration analysis provides your most accessible entry point. Rotating equipment including motors, pumps, gearboxes, and fans can all benefit from vibration monitoring that detects bearing wear, misalignment, and imbalance before catastrophic failure occurs. Portable vibration analyzers require minimal investment while enabling your technicians to establish baseline readings and track degradation trends over time.

For example, a beverage bottling plant can use handheld analyzers to check conveyor motors during weekly rounds. Identifying developing problems before a midnight breakdown halts the filling line.

Cycle counters or runtime meters enable condition-based maintenance for equipment where usage varies significantly. A stamping press that operates intermittently based on production schedules benefits more from maintenance triggered after specific usage thresholds than from arbitrary time intervals. Install simple counters that integrate with your maintenance management platform to generate work orders automatically when usage thresholds are reached.

For example, a packaging equipment manufacturer can track actual cycle counts on each machine rather than calendar time, ensuring maintenance aligns with real wear patterns.

Create connected work orders and mobile access

Connected work orders form the foundation of effective maintenance data flow. Your technicians should log every maintenance activity through the maintenance management platform, capturing work performed, time invested, parts consumed, and asset conditions observed. The discipline of consistent data entry proves as important as the technology platform itself.

You can build your technician logging habits through clear expectations, streamlined mobile interfaces, and regular data quality reviews.

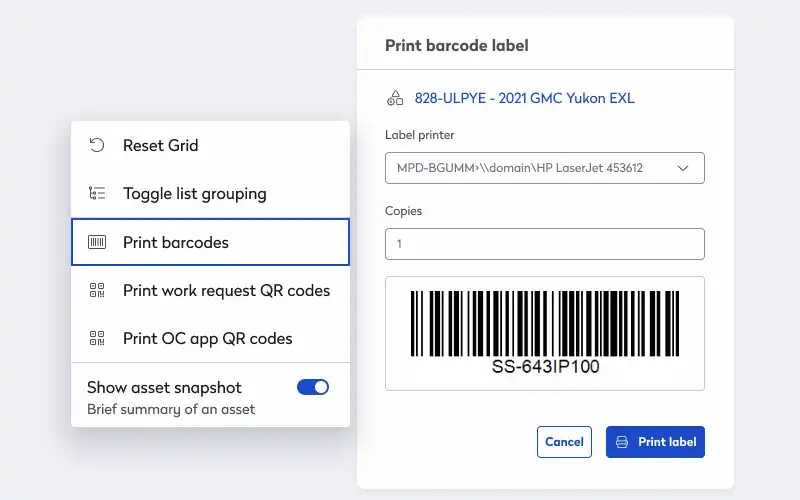

Modern asset management platforms provide barcode scanning capabilities that enable your technicians to quickly access critical equipment data, open work orders, maintenance history, photos, manuals, and other documents. When your technician arrives at a malfunctioning injection molding machine, they can scan the equipment barcode with their mobile device and instantly see the last three repairs, current parts inventory, and OEM troubleshooting guides.

Consolidate your asset information into a single platform that connects maintenance histories with procurement data, operating specifications, and performance metrics. When your technicians respond to equipment issues, they need immediate access to previous repair histories, parts availability, manufacturer documentation, and operating parameters without searching through multiple disconnected systems.

For example, a chemical processing plant managing reactor vessels across production areas can view every maintenance event for similar equipment, identifying whether a recurring issue affects one unit or represents a systemic problem requiring engineering intervention.

Track performance with dashboards and automated reports

Establish key performance indicators that measure your maintenance program effectiveness through automated reporting capabilities. Track mean time between failures by asset class, maintenance cost per unit of production, preventive maintenance compliance rates, and unplanned downtime trends. Review these metrics monthly with your maintenance team, investigating negative trends and celebrating improvements.

Your maintenance management platform dashboards provide real-time visibility into maintenance operations. A packaging film manufacturer might discover through dashboard analytics that one production line experiences twice as many emergency repairs as similar lines, triggering investigation into whether operator training, equipment age, or process parameters contribute to elevated failure rates. The system automatically tracks total maintenance spend by asset, enabling data-driven repair-versus-replace decisions.

Then use your consolidated data to refine maintenance strategies continuously. When an asset class shows increasing failure rates despite consistent PM compliance, the data signals your need for strategy adjustment. Perhaps your PM intervals require tightening, or condition-based triggers would prove more effective than time-based schedules.

When to use PM vs PdM: a practical trigger matrix

Different maintenance strategies suit different equipment types, operating conditions, and business contexts. Understanding when to apply preventive versus predictive approaches enables optimal resource allocation.

Preventive maintenance triggers can work best for:

- Manufacturer-recommended intervals: Equipment where OEM guidance provides reliable scheduling direction

- Safety-critical systems: Emergency lighting, fire suppression systems, and fall protection devices requiring regular inspection regardless of condition

- Low-cost inspections: Assets where inspection tasks cost significantly less than failure consequences

- Stable operating conditions: Equipment running under consistent environmental and operational parameters

- Predictive maintenance triggers can deliver better results for:

- Aging critical assets: Equipment where remaining useful life varies based on operating stress and accumulated wear

- High downtime costs: Assets where failures justify monitoring investment through substantial operational impact

- Variable operating conditions: Equipment subjected to changing loads, speeds, or environmental factors

- Measurable condition signals: Rotating equipment, thermal patterns, or other parameters with clear degradation indicators

The optimal trigger strategy evolves as equipment ages, operating conditions change, and maintenance capabilities mature. So, make sure to review and adjust trigger assignments on a fixed schedule, using accumulated performance data from your digital maintenance management platform to refine your approach continuously.

Chart your path to proactive maintenance

Mid-market manufacturing leaders face legitimate budget constraints that make wholesale, all-at-once maintenance transformation unrealistic. The solution is sequencing: master preventive discipline first, then introduce predictive capabilities where they deliver the highest ROI. It’s an approach that delivers measurable reliability improvements without requiring large upfront investments.

Organizations that build strong PM fundamentals create the data foundation and team habits necessary for successful PdM scaling. Focused pilots prove value quickly, building organizational confidence while demonstrating tangible returns. The combination of improved uptime, reduced maintenance costs, and extended asset life cycles creates a self-funding improvement cycle that advances your reliability maturity over time.

Ready to build your maintenance roadmap? Get practical implementation steps and best practices in our complete preventive maintenance guide.