The challenges continue to climb for facility and maintenance managers. Manufacturers expect input costs to increase by an average of 5.4% over the next year, according to Deloitte’s 2026 Manufacturing Industry Outlook. Meanwhile, aging equipment and an aging, retiring workforce are amplifying repair and downtime costs, with 25% of the manufacturing workforce now at or beyond eligible retirement age.

Reliability centered maintenance (RCM) helps you overcome these challenges through a systematic process that matches critical assets with the most cost-effective maintenance strategies. Instead of applying blanket preventive maintenance schedules or running equipment to failure, RCM enables organizations to optimize resource allocation based on asset criticality, failure modes, and business impact.

Key takeaways

- Organizations struggle to balance short-term operational demands with long-term asset stewardship, often resulting in deferred maintenance and reactive decision-making that perpetuates cycles of underinvestment

- RCM analyzes seven critical questions about each asset to determine optimal maintenance strategies, moving beyond manufacturer recommendations to address facility-specific operating conditions and business requirements

- Effective implementation requires understanding asset criticality, analyzing failure modes and consequences, and continuously refining maintenance approaches as business goals and equipment conditions evolve over time

Understanding how organizations achieve these results requires examining the fundamental principles that differentiate RCM from traditional maintenance approaches.

What is reliability centered maintenance and why does it matter?

Reliability centered maintenance started in the aviation industry, where the complexity of aircraft systems, heavy operational demands, and catastrophic failure risks required a more sophisticated framework than time-based preventive maintenance alone could provide.

RCM focuses on identifying the maintenance strategy that delivers maximum reliability at the lowest total cost for each specific asset. The guiding principle recognizes that different assets require different management approaches. Some assets demand continuous high-tech monitoring through predictive maintenance programs, while others perform optimally under run-to-failure models.

The pressure to reduce costs while maintaining performance creates tension that often leads to substantial deferred maintenance and reactive firefighting. Organizations implement RCM to break this cycle by aligning maintenance strategies with broader business goals while demonstrating the tangible value of proactive asset management.

Vaughn Halliday, Manager of Support Services and Facilities for the Central Bank of Trinidad & Tobago, explained in a recent Asset Champion podcast episode, “Organizations face the challenge of balancing short-term operational demands against that long-term asset stewardship. There’s always this constant pressure, especially in these modern days, to reduce costs, but there’s still the expectation for high-performance, sustainable environments, and that expectation keeps rising.”

What are the seven RCM questions every facility manager should ask?

RCM methodology involves working through seven fundamental questions for each asset or system. These questions create a structured framework that moves organizations from assumptions to evidence-based maintenance decisions.

What is the asset supposed to do, and what are its performance standards?

The first question establishes what the asset or equipment is supposed to do and the associated performance standards. Organizations examine manufacturer documentation to understand the scope of functions, limitations, and proper methods of use relating to safety and environmental measures. An industrial scale, for example, may have specific weight limits that affect accuracy, plus precise requirements for item placement and environmental conditions to ensure reliable operation.

How well is the asset performing compared to desired outcomes?

Organizations assess current asset performance against desired outcomes. A conveyor belt moving 5,000 boxes between breakdowns, with each breakdown lasting three hours, might have the potential to move 7,000 boxes between failures while reducing breakdown duration to two hours based on manufacturer specifications, maintenance team expertise, and data in the facility management system.

In what ways can this equipment fail?

Facilities determine exactly how equipment can fail to provide required functions. The analysis identifies whether failures relate to specific components or represent systemic issues, how often failures occur, and whether failure patterns affect multiple units of the same equipment type across the organization.

What causes each type of failure?

Understanding why, when, and how equipment failures occur provides critical insight. Heavy-use equipment may suffer from operating fatigue. Environmental conditions, including heat, cold, or moisture exposure, create stress. Human error and inherent design or manufacturing flaws also contribute to equipment failure. Identifying root causes enables organizations to address underlying issues rather than treating symptoms.

What happens when the asset fails?

Failure effects range from nearly undetectable performance degradation to complete loss of function. Equipment failure might decrease output speed or quality, or it might result in complete operational shutdown. Organizations evaluate how failures impact productivity, operations, capital costs, safety risks for operators, environmental compliance, and overall asset integrity.

Why does this failure matter to the overall business?

Beyond financial and logistical consequences, facilities assess safety risks and environmental impacts associated with potential failure mode. The analysis considers how failures affect asset conditions and determine the appropriate level of intervention based on total business impact.

What proactive maintenance prevents or reduces failure consequences?

Asset maintenance and repair histories reveal breakdown patterns that guide preventive measures. A conveyor belt that typically runs 5,000 boxes before requiring repairs might benefit from visual inspections after every 4,500 boxes to extend uptime. However, organizations must balance what they can do against what they should do. When the cost and complexity of preventing breakdown exceed the value of increased uptime, run-to-failure remains the optimal strategy.

What technology and software enable reliability centered maintenance?

Modern facility management platforms provide the data foundation necessary for effective RCM programs. IFMA’s description of their Rise of the FM Analyst report captures the continuing shift in how facilities teams approach operations: “Data isn’t just for IT anymore. This report highlights how FMs are increasingly using analytics to tell the story behind facility operations. It explores how curiosity, storytelling, and data literacy are reshaping FM roles and how teams can build analytical capacity for smarter, faster decisions.”

Organizations that digitize maintenance workflows through comprehensive systems gain centralized visibility into asset performance, failure patterns, and maintenance effectiveness.

Automated preventive maintenance scheduling

Preventive maintenance capabilities transform RCM implementation by automating the creation and execution of asset-specific maintenance strategies. Once you determine the optimal maintenance approach for each asset through RCM analysis, the platform generates customized preventive maintenance schedules that align precisely with your criticality assessments and failure mode analysis.

The system automatically creates work orders based on calendar intervals, meter readings, or runtime hours depending on which trigger makes sense for each asset class. For a conveyor belt requiring inspection every 4,500 boxes, the platform tracks throughput and generates inspection work orders at the exact threshold. For HVAC equipment serving sensitive environments, it schedules filter changes and system checks based on operating hours rather than arbitrary monthly intervals.

Technicians access complete maintenance histories at the point of work through mobile applications, ensuring they know exactly what was done during previous inspections, what parts were replaced, and what issues were flagged. The platform captures structured data from each maintenance activity, building the asset intelligence necessary to refine RCM strategies over time.

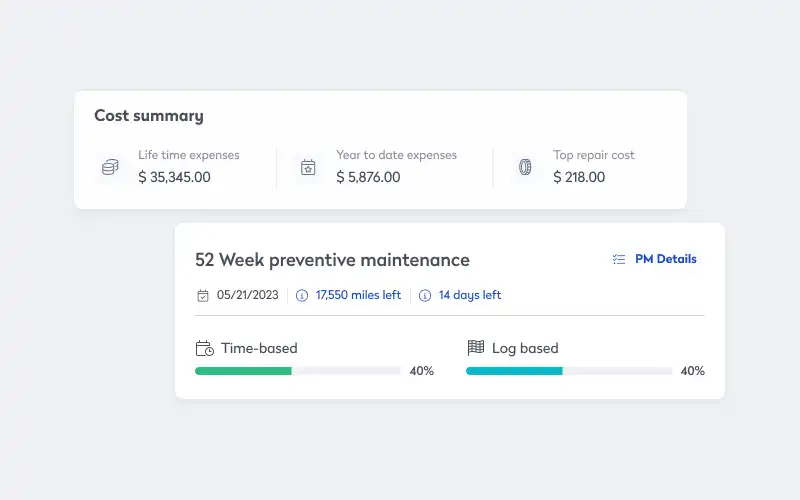

Asset performance analytics and reporting

Asset management platforms deliver analytics that reveal failure patterns invisible in spreadsheets or paper-based systems. The platform aggregates maintenance histories across identical assets at multiple locations, exposing systematic issues that might appear as isolated incidents when viewed individually.

Performance dashboards track key RCM metrics including mean time between failures, maintenance costs per asset, and unplanned downtime trends. Facilities managers can filter data by asset type, location, criticality level, or maintenance strategy to identify which approaches deliver the best results. The analytics show exactly which assets consume maintenance resources disproportionately, guiding decisions about when to repair versus replace.

Automated reporting demonstrates RCM value to organizational stakeholders by quantifying improvements in uptime, cost reductions from optimized maintenance strategies, and compliance rates for preventive maintenance schedules. The data enables evidence-based conversations about maintenance investments rather than subjective assessments of value.

How to implement reliability centered maintenance: Five steps

Organizations beginning RCM implementation should follow a structured approach that builds momentum while demonstrating early value. The following five steps create a systematic path from analysis to results.

- Evaluate and rank all assets by criticality. Start by evaluating assets in terms of criticality, considering costs for maintenance and labor, risk of injury, environmental damage, lost productivity, and compliance-related fines. Remember that identical assets can have different criticality levels depending on their function within operations. Create a prioritized list ranking assets from most to least critical, then focus initial RCM analysis on the highest-criticality assets to maximize early impact

- Conduct systematic failure mode analysis on critical assets. For top-priority assets, work through the seven RCM questions systematically. Gather maintenance histories, failure records, and performance data from your maintenance management platform while engaging maintenance technicians and operators who understand day-to-day equipment behavior. Document failure modes, frequencies, and business impacts, then identify whether current maintenance strategies align with actual failure patterns and business risk

- Develop asset-specific maintenance strategies matched to failure modes. Based on failure analysis, determine the optimal maintenance approach for each asset. Consider preventive maintenance with scheduled inspections and tasks, predictive maintenance using condition monitoring, run-to-failure for low-criticality assets with minimal failure consequences, and condition-based maintenance that triggers interventions when specific thresholds are reached

- Establish key performance indicators and track results against baselines. Define metrics that demonstrate RCM impact, including unplanned downtime reduction, mean time between failures, preventive maintenance compliance rates, maintenance cost per asset, and overall equipment effectiveness. Measure results against pre-RCM baselines to quantify improvements and build the business case for continued investment

- Create continuous improvement cycles with regular strategy reviews. Schedule periodic reviews of maintenance strategies, particularly after significant operational changes, major equipment failures, or shifts in business priorities. Update RCM analysis when new failure modes emerge or when cost structures change for different maintenance approaches, ensuring your strategies evolve with your assets and business requirements

Following these sequential steps provides a framework for transitioning from traditional reactive maintenance to strategic reliability centered practices that deliver measurable operational and financial results.

Start optimizing your maintenance strategy with RCM

RCM helps you move facilities from reactive firefighting to strategic asset optimization. It’s a systematic framework that provides objective criteria for matching each asset with its optimal maintenance strategy while demonstrating tangible value to organizational stakeholders. Organizations that successfully implement RCM achieve measurable results including reductions in maintenance costs, decreases in unplanned downtime, and significantly extended asset life cycles.

With the right technology platform supporting data-driven decision-making, maintenance teams can move beyond manufacturer recommendations to develop truly optimized strategies tailored to their specific operating conditions and business requirements.

Ready to learn more about how facility management technology enables RCM success? Speak with an expert.