Communication breakdowns, inconsistent processes, and delayed responses from across sites can quickly escalate into costly disruptions. When facility management teams need to work across cities or even countries, staying aligned requires more than just email chains and spreadsheets.

A modern facility management solution delivers the key features that help you bridge gaps, bringing clear collaboration to complex operations.

Key takeaways

- Modern facility management solutions provide a single, cloud-based platform where all locations feed into one source of truth, eliminating manual data collection, ensuring everyone works from the same information

- Features like real-time work order management, integrated service request systems, and inventory and asset tracking tools help facility teams collaborate effectively across multiple locations by providing visibility into work orders, requests, and asset maintenance histories, reducing delays and improving productivity

- Analytics dashboards consolidate data from all locations into clear, actionable reports, so facility managers can track KPIs, identify trends, benchmark performance, and export reports for leadership and compliance reviews, making informed decisions easier

By understanding the core challenges and solutions presented, organizations can better navigate the complexities of multi-site management and improve overall collaboration.

Close the gaps: Centralized access for clearer visibility and faster action

Facility managers working across multiple locations often face the same core challenge of fragmented data. Whether it’s chasing updates or reconciling reports, the lack of a unified system slows down decisions and creates blind spots.

For example, a regional facility manager overseeing five sites spent hours each week chasing updates from local teams. Each location used its own spreadsheet, and by the time data was compiled, it was already outdated. The manual process created blind spots and slowed down decision-making.

At another company, the corporate FM struggled to prepare monthly reports for leadership. Each site submitted data in different formats, and reconciling the numbers took days. The lack of standardization made it hard to spot trends or justify budget requests.

One platform, one source of truth for every location and every team

A modern facility management solution offers a single, cloud-based platform where all locations feed into one source of truth, eliminating manual data collection and ensures that everyone, from technicians to executives, is working from the same information.

With centralized access, you can:

- View real-time updates from every location

- Standardize data formats and reporting processes

- Set role-based permissions to control who sees what

- Access dashboards from any device, anywhere

So, back at the regional company, the FM now logs into a dashboard that shows live data from all five sites. They can spot trends, flag issues, and share insights with leadership in minutes—not days. The time spent chasing updates is gone, replaced by proactive planning and faster responses.

At the other company, the FM no longer worries about monthly reporting. Each site enters data into the same system, using the same format. The dashboard automatically compiles the numbers, highlights anomalies, and generates charts that leadership can review instantly. Budget conversations are now backed by consistent, credible data.

Respond quickly and confidently with real-time work order management

Facility teams often lose valuable time when they try to track work orders manually. Without a centralized system, requests slip through the cracks, updates are delayed, and visibility suffers, especially across multiple locations.

For example, a technician at a remote warehouse flagged a broken HVAC unit, but the request got buried in email threads. The delay led to uncomfortable working conditions and a drop in productivity, while a maintenance manager at a multi-site retail chain struggled to track open work orders. Some tasks were completed but never logged, while others were forgotten entirely.

Without visibility, it’s impossible to know what the team has done and what they still need to do.

Real-time work order tools keep teams aligned and issues moving forward

Real-time work order management tools help your team submit, track, and close requests from mobile devices. You can assign tasks instantly and monitor progress across locations, prioritizing tasks based on urgency and impact, and escalation workflows to ensure the team is on top of critical issues. Status updates are visible to all stakeholders, reducing the need for follow-up emails and phone calls.

With centralized work order management, you can:

- Submit and track requests from any location

- Assign tasks instantly and monitor progress in real time

- Prioritize issues based on urgency and business impact

- Reduce delays with automated alerts and escalation workflows

That means at the warehouse, the technician now submits the HVAC issue through an app. The manager sees it immediately, assigns it to the right person, and tracks the repair in real time.

They fix it the same day, and productivity stays on track, while at the retail chain, the maintenance manager opens a dashboard showing every open work order across all stores, and the team can finally focus on solving problems instead of chasing paperwork.

Give every employee a voice with an integrated service request system

Facility teams can’t fix what they don’t know about, and when communication breaks across locations, small issues quickly escalate.

Without a consistent way to report problems, employees feel unheard, and facility managers lose visibility into what’s happening on the ground.

For example, employees at satellite offices often felt ignored when submitting maintenance requests. Without a formal system, their emails were easy to overlook, and small issues became big problems.

Meanwhile, at a manufacturing company, frontline workers had no clear way to report facility issues. They relied on verbal requests during shift changes, which were often forgotten or miscommunicated. The result was delayed repairs and growing frustration.

A unified request system improves communication and builds trust across teams

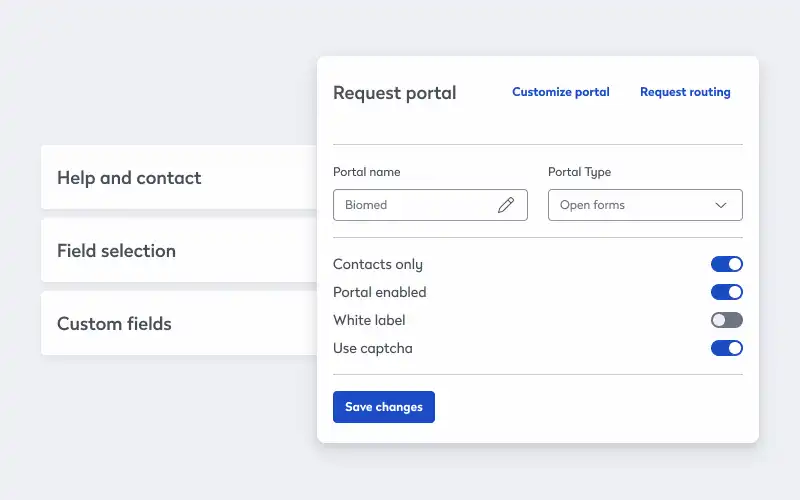

An integrated service request system gives everyone on your team a simple, consistent way to report issues. Requests are automatically routed to the right team and tracked through resolution.

The interface is intuitive, allowing employees to submit requests from their phones or desktops. Real-time status updates keep everyone informed, and analytics help facility managers identify recurring issues and improve service delivery.

With a centralized request system, you can:

- Give every employee a clear way to report issues

- Route requests automatically to the right team

- Track progress and share real-time updates

- Use data to identify patterns and improve service

At the satellite office, employees now use a mobile app to submit requests. They receive updates as the issue progresses, and the FM team can spot patterns like recurring HVAC complaints and take proactive steps to improve conditions.

In the manufacturing plant, workers submit requests directly from the floor. The team can use the system to log each issue, route it to the right technician, and track resolution. Repairs happen faster, and workers feel heard and supported.

Stop wasting resources with inventory and asset visibility

Managing inventory and assets across multiple locations is complicated, but without shared visibility, it’s also inefficient. Duplicate orders, missed service windows, and premature replacements can all come from a lack of communication and coordination.

Imagine a technician ordered a replacement part for a generator, unaware that the same part was already stocked at a nearby location. Meanwhile, a facility manager overseeing multiple campuses struggled to track asset lifecycles. Equipment was serviced inconsistently, and some assets were replaced prematurely simply because their histories were missing.

Shared visibility helps teams coordinate inventory and extend asset lifecycles

Inventory and asset tracking tools provide a unified view of parts, equipment, and usage across all locations. You can see real-time inventory levels across sites, track maintenance histories and service records, set alerts for low stock or upcoming service needs, and avoid unnecessary purchases and delays.

With shared inventory data, your technician sees that the needed part is available at a nearby site. They request a transfer, complete the repair the same day, and avoid unnecessary spending.

At the campus network, you now have full visibility into asset histories, able to see which equipment is due for service, which parts are in stock, and which assets are nearing end-of-life. Finally, you’re making data-backed decisions.

Make confident, data-backed decisions with cross-location analytics

Facility managers need more than raw data. They need insights. When information is scattered across systems and sites, it’s hard to see the big picture and make informed decisions.

Leadership asked for a quarterly report comparing maintenance costs across regions. The facility team scrambled to gather data from different systems, leading to inconsistent numbers and missed insights, while at another organization, the FM team couldn’t explain why energy costs were rising at one location. Without trend data or benchmarks, they had no way to investigate or justify changes.

Analytics dashboards bring clarity and confidence to multi-site decisions

Analytics dashboards consolidate data from all locations into clear, actionable reports. You can track KPIs for maintenance, space, and asset performance, identify trends and recurring issues across sites, benchmark performance to spot outliers and opportunities, and export reports for leadership and compliance reviews.

So, at the first company, the FM team now pulls up a dashboard that compares maintenance costs across regions in seconds. They identify which sites need attention, propose targeted improvements, and present clear data to leadership.

At the second organization, the FM team uses energy data to pinpoint the source of the cost increase. They identify an outdated HVAC system, propose a replacement, and back it up with performance benchmarks from other sites.

How ACE Recycling & Disposal improved cross-site collaboration with smarter facility tools

ACE Recycling & Disposal, the largest independent waste hauler in the western United States, operates across 18 locations and manages more than $10 million in inventory and over 550 assets.

Before adopting a modern facility management solution, their team faced a series of operational challenges that made it difficult to stay aligned across sites. They relied on manual tracking for inventory and assets, which led to accuracy rates as low as 30–45%. Without centralized data, compiling performance metrics was time-consuming and inconsistent, limiting their ability to secure funding or make strategic decisions.

With the right technology in place, ACE saw measurable improvements across the board. Inventory accuracy jumped to 95%, thanks to centralized tracking and real-time visibility. Their team now processes 5,000 work orders and 2,000 preventive maintenance tasks each month with streamlined workflows that span all 18 locations.

In fact, with standardized data and automated dashboards, ACE secured $2 million in grants.

ACE’s story shows what’s possible when facility managers have the tools to connect locations, automate processes, and make data-driven decisions.

Read the full success story.