Every organization, from large manufacturing plants to healthcare facilities and corporate offices, depends on a vast network of physical assets — machinery, IT equipment, medical devices, and vehicles — all working together to drive daily operations. Keeping track of these assets efficiently ensures seamless workflows, cost savings, and optimized maintenance planning.

With the right asset tracking system in place, businesses can easily locate equipment when it’s needed, reduce unnecessary purchases, and ensure assets are well-maintained throughout their lifecycle. Instead of scrambling to find missing items or dealing with unexpected breakdowns, organizations can stay ahead with real-time visibility into asset usage, condition, and performance.

Implementing asset tracking software provides a proactive approach to managing resources. With instant access to data on where assets are, who is using them, and when they need servicing, businesses can optimize their investments, minimize disruptions, and ensure compliance with ease. By transforming asset management from a reactive process into a strategic advantage, organizations can improve efficiency, cut costs, and extend the life of their equipment.

Beyond spreadsheets: The need for smarter asset management

For years, many companies have relied on manual tracking methods — spreadsheets, handwritten logs, or even simple visual checks. While these methods might work on a small scale, they quickly become unreliable as organizations grow. Human error creeps in, updates are forgotten, and tracking assets across multiple locations turns into a logistical nightmare.

Spreadsheets don’t tell you when an asset was last serviced, they don’t alert you when inventory is running low, and they certainly don’t provide real-time data on asset usage. As a result, organizations over-purchase, underutilize, and struggle with maintenance inefficiencies that could easily be avoided with the right technology.

This is why asset tracking software is now essential. Unlike traditional methods, modern tracking solutions use barcodes, RFID tags, GPS, and IoT sensors to provide continuous, automated tracking of assets. Every movement is logged, every maintenance update is recorded, and every asset is accounted for, creating a single source of truth for inventory and lifecycle management.

When organizations move beyond spreadsheets and embrace asset tracking software, they gain control over their assets in a way that was never possible before.

Optimizing inventory management with asset tracking software

One of the most immediate benefits of asset tracking software is its impact on inventory management. Businesses frequently struggle with overstocking, stockouts, and wasted resources — all of which stem from poor visibility into inventory levels.

With real-time tracking, organizations can see exactly what they have, where it is, and when it needs to be replenished. This eliminates guesswork and ensures that inventory is managed efficiently. No more last-minute rush orders, no more costly emergency purchases, and no more wasted stock sitting unused.

For industries like manufacturing and healthcare, where supplies and equipment must be available at all times, the ability to track inventory in real-time is invaluable. Hospitals, for example, can prevent critical shortages of medical devices by ensuring that all assets are accounted for and properly maintained. Similarly, factories can avoid production slowdowns by tracking spare parts and raw materials, ensuring that replacements are ordered before they run out.

Inventory optimization isn’t just about cost savings — it’s about keeping operations running smoothly and eliminating disruptions that slow down productivity.

Extending asset lifecycles with smart maintenance strategies

Beyond inventory, asset tracking software plays a crucial role in lifecycle management. Every asset has a lifespan, and without proper tracking, businesses either replace equipment too early, wasting money, or wait until it fails, leading to costly downtime.

With asset tracking software, organizations can monitor asset performance, track maintenance history, and schedule servicing based on real-time data. Instead of relying on outdated, time-based maintenance schedules, businesses can shift to condition-based maintenance, where servicing is performed only when it’s actually needed.

This approach has two major advantages:

- It extends asset lifespans by ensuring that equipment is well-maintained throughout its lifecycle. Proper servicing prevents wear and tear, reducing the likelihood of premature failure.

- It prevents unnecessary maintenance that wastes time and resources. When maintenance is scheduled based on real-time asset condition, businesses avoid servicing equipment that’s still in peak performance mode.

For industries with expensive, high-value assets — such as construction, logistics, and healthcare — this can translate to millions of dollars in savings over time.

How asset tracking software enhances compliance and security

In industries where regulatory compliance is critical, asset tracking software helps organizations stay audit-ready. Government agencies, healthcare facilities, and financial institutions all face strict regulations regarding asset management, and failing to maintain proper records can result in hefty fines or legal liabilities.

By automatically recording when an asset was last inspected, who used it, and whether it meets compliance standards, asset tracking software ensures that organizations can provide accurate reports on demand. This is particularly important in industries like pharmaceuticals, aviation, and food production, where equipment must meet strict quality control and safety standards.

Beyond compliance, asset tracking software also enhances security. Lost or stolen assets can be a major financial burden, but with GPS tracking and location-based monitoring, companies can quickly recover missing equipment and prevent unauthorized usage.

By knowing exactly where every asset is at all times, businesses reduce risks, improve accountability, and maintain a more secure operational environment.

The future of asset management: AI and IoT integration

As technology advances, asset tracking software is becoming more intelligent and predictive. The integration of AI and IoT sensors is enabling businesses to automate asset tracking, predict maintenance needs, and make data-driven decisions like never before.

IoT-enabled sensors can now detect anomalies in asset performance, alerting maintenance teams before failures occur. AI-driven analytics can identify patterns in asset usage, helping businesses optimize their resources and make smarter purchasing decisions.

These advancements mean that asset tracking software is no longer just a logistics tool — it’s a strategic asset in itself, helping organizations reduce costs, improve efficiency, and drive long-term profitability.

Why every business needs smarter asset tracking

The days of manual asset tracking are over. Businesses that still rely on spreadsheets, paper logs, or outdated tracking methods are losing money, wasting time, and increasing risk. Asset tracking software offers a smarter, more efficient way to manage inventory and extend asset lifecycles, providing real-time visibility, automated workflows, and predictive insights that drive better decision-making.

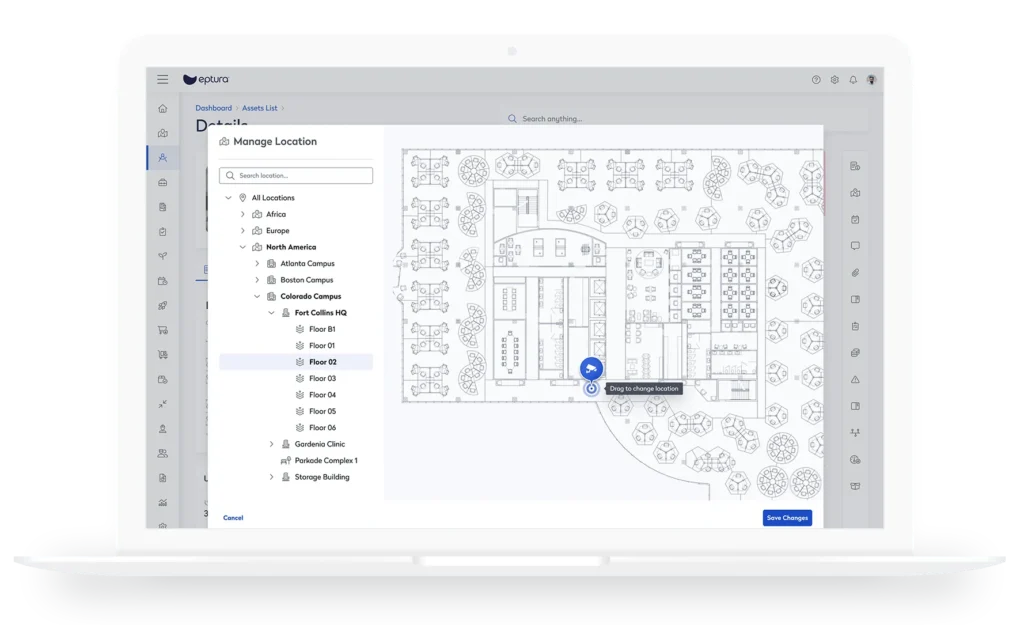

Eptura’s enterprise asset management software offers a comprehensive solution designed to maximize the performance of your assets. With features such as preventive maintenance scheduling, asset lifecycle tracking, and simplified task management, Eptura enables organizations to keep their assets running longer, reduce downtime costs, and boost business performance. Book a demo to see it in action today.