Maintenance departments play a critical role in ensuring operational continuity, safety, and asset reliability across facilities. Even highly skilled teams, however, face challenges when communication is fragmented or inconsistent. Computerized maintenance management systems (CMMS) can be instrumental in helping organizations build a culture of collaboration that then moves them away from reactive, siloed workflows toward coordinated, data-driven maintenance operations.

Key takeaways

- A CMMS provides clear communication and shared visibility, reducing missed tasks and duplicate efforts by ensuring technicians and supervisors have access to the same real-time data

- By enabling real-time updates and centralized visibility into active work orders, a CMMS helps eliminate delays in communication, especially across shifts, thereby minimizing disruptions and protecting asset integrity

- A CMMS supports effective maintenance planning by providing insights into technician availability, skill sets, and historical performance, and preserves institutional knowledge by acting as a centralized repository for work order history and resolution details

Without shared visibility and strong communication, even routine maintenance can quickly become an expensive guessing game. With the right combination of collaboration tools, your maintenance teams can work together better.

What are the challenges of siloed maintenance work?

Siloed maintenance operations often result in fragmented communication, duplicated efforts, and inconsistent task execution. When technicians, supervisors, and planners lack access to shared data, routine activities become disjointed, and efficiency and reliability suffer.

Technicians miss work orders, misunderstand priorities, and delay critical updates, especially when teams lack shared visibility across shifts or locations.

The lack of coordination not only affects day-to-day efficiency but also undermines long-term planning and compliance. Without a centralized system to track performance, assign responsibility, and document outcomes, teams struggle to identify patterns, prevent recurring issues, and maintain accountability.

Over time, these gaps can lead to increased downtime, higher operational costs, and reduced confidence in the maintenance function.

What are the long-term benefits of collaborative maintenance tools?

Collaborative maintenance tools bring numerous benefits, including improved coordination, faster response times, and better resource allocation, all of which can help teams transition from reactive to proactive maintenance operations.

Fewer missed tasks, less duplicate effort

Clear communication and shared visibility are foundational to effective maintenance coordination. When technicians and supervisors operate with access to the same real-time data, it becomes significantly easier to manage daily workloads without overlap or confusion.

For example, in a facility without centralized task tracking, managers might accidently dispatch two separate technicians to inspect the same HVAC unit, resulting in wasted labor hours and delayed attention to other priorities. A CMMS helps mitigate these sorts of oversights by providing a unified view of all active, scheduled, and completed work orders.

Supervisors can assign tasks with confidence, and technicians can verify assignments before beginning work.

Over time, better coordination leads to a measurable reduction in overdue work orders and a noticeable improvement in first-time fix rates. Maintenance teams spend less time backtracking or redoing work and more time executing tasks that directly support operational goals.

Faster response times

Timely response to maintenance issues is critical to minimizing disruption and protecting asset integrity. In many facilities, delays in communication, especially across shifts, can result in minor problems escalating into costly failures. A CMMS helps the team eliminate these delays by enabling real-time updates and centralized visibility into active work orders.

Consider a scenario where a leak is reported during the night shift. Without a shared system, the morning crew might not receive the information until hours later, delaying the response and increasing the risk of water damage.

With a CMMS in place, the team can log the issue immediately, so the next shift can access the details as soon as they begin work.

The higher level of responsiveness directly impacts key metrics, including:

- Mean Time to Repair (MTTR): By streamlining communication and ensuring technicians have immediate access to issue details, CMMS platforms help teams reduce the time it takes to diagnose and resolve problems

- Mean Time Between Failures (MTBF): Faster interventions prevent small issues from compounding, which helps extend the operational life of equipment and reduce the frequency of breakdowns

- Work Order Response Time: CMMS platforms help teams automate notifications and enable mobile access. A technician can receive and accept tasks directly from their device, eliminating delays caused by manual dispatching or paper-based systems

Improved response times are not just about speed. They’re about precision, coordination, and the ability to act immediately on accurate information.

Improved planning and resource allocation

Effective maintenance planning depends on more than just assigning tasks. It requires a clear understanding of technician availability, skill sets, and historical performance. Without access to this data, supervisors often rely on assumptions or manual tracking, which can lead to uneven workloads, underutilized resources, and missed opportunities for optimization.

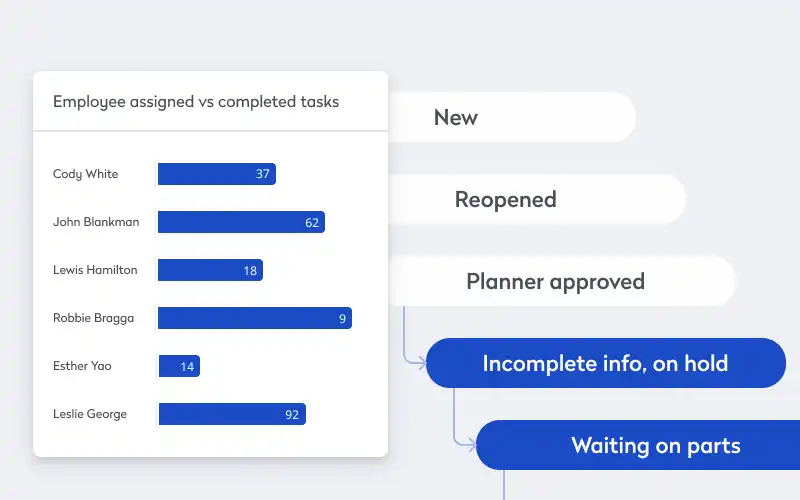

A CMMS provides the department with visibility into technician schedules, task completion rates, and time-on-task metrics, allowing supervisors to make informed decisions about staffing and task distribution.

For example, if one technician consistently completes work orders efficiently and with minimal follow-up, they may be better suited for complex or time-sensitive assignments. Identifying technicians who require additional support or training becomes easier when performance data is centralized and accessible.

These insights support stronger labor utilization rates, ensuring that available resources are matched to actual operational needs. It also contributes to more consistent preventive maintenance compliance, as supervisors can plan recurring tasks around technician capacity rather than reacting to last-minute availability gaps.

Over time, there’s a more balanced workload, fewer scheduling conflicts, and improved overall efficiency across the maintenance team.

Consistent knowledge transfer

In many maintenance departments, critical operational knowledge lives in the heads of experienced technicians. When those individuals retire, change roles, or are unavailable, that knowledge can be lost, resulting in longer resolution times, repeated mistakes, and increased downtime.

Leveraging a CMMS, managers can preserve institutional knowledge by acting as a centralized repository for work order history, technician notes, photos, and resolution details. When a technician documents how they resolved a recurring issue with a specific asset, that information becomes part of the system’s record.

New hires or less experienced team members can then reference these entries to understand past approaches, avoid common pitfalls, and build confidence in their decision-making.

Structured knowledge transfer reduces the impact of turnover and supports smoother onboarding. It also helps standardize maintenance practices across shifts and locations, ensuring that teams operate with consistent expectations and access to the same information.

In the long term, it strengthens the department’s resilience and reduces the risk of downtime caused by gaps in experience or communication.

What are some of the key CMMS features that support teamwork?

Key CMMS features that support teamwork include maintenance history documentation, workload balancing tools, mobile access, and task-level commenting.

Collectively, they help create a centralized platform for real-time collaboration and consistent practices.

Maintenance history and asset-level documentation

Teams rely on maintenance history and asset-level documentation to preserve institutional knowledge and support consistent standards. Every task the team performs on an asset goes into the record, including technician notes, resolution steps, and supporting documentation.

When technicians encounter recurring issues, they can review how similar problems were resolved in the past, helping them make informed decisions and avoid repeating ineffective solutions.

New technicians use this documentation to learn from previous work, while experienced team members reference past repairs to identify patterns or root causes.

By maintaining a shared archive of knowledge, teams reduce downtime caused by gaps in experience and strengthen overall performance.

Technician workload balancing and assignment tools

Supervisors use workload balancing tools to assign tasks based on technician availability, skill sets, and current workload. Instead of relying on manual scheduling or assumptions, they can view real-time data to distribute assignments fairly and efficiently, helping prevent overloading certain team members and ensures that specialized tasks go to technicians with the right experience.

When a technician has a strong track record with a particular asset type, supervisors can prioritize them for related work.

Over time, this leads to more balanced workloads, improved morale, and higher task completion rates.

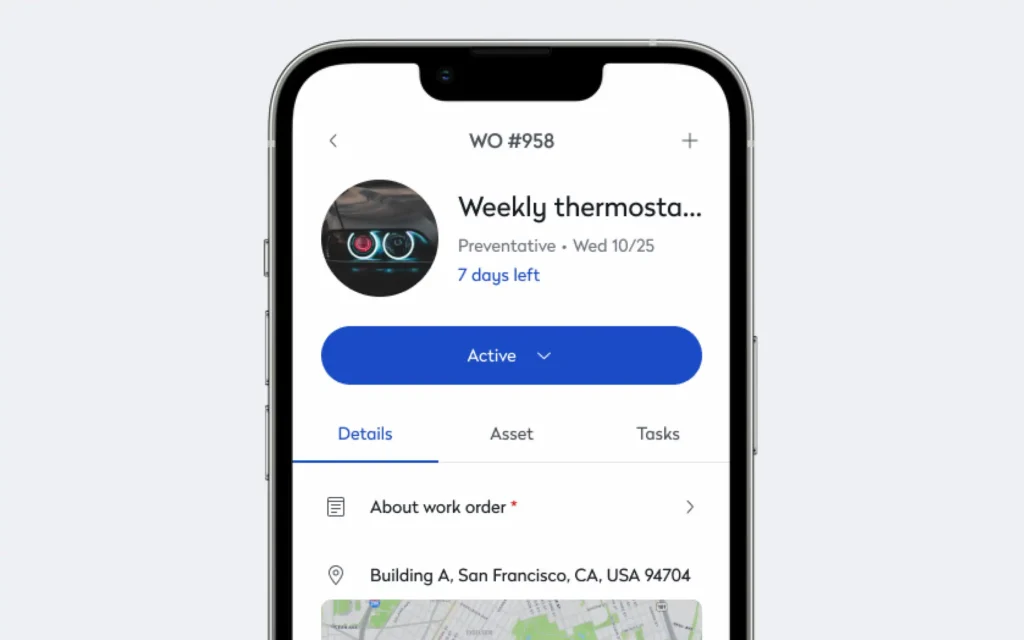

Mobile work order access and updates

Technicians use mobile access to interact with the CMMS directly from the field. They receive assignments, update task statuses, upload photos, and document work without returning to a central workstation, which is especially valuable in large facilities or multi-building campuses, where travel time between locations can slow down communication and delay task completion.

For example, a technician repairing a rooftop HVAC unit can close out the task and flag follow-up needs immediately, allowing the next shift to continue without interruption.

Supervisors also benefit from mobile visibility, using real-time updates to adjust priorities and respond to changing conditions more effectively.

Task-level commenting and collaboration threads

Technicians and supervisors use task-level commenting to communicate directly within individual work orders, allowing them to ask questions, share updates, and clarify instructions in context, eliminating the need for external emails or verbal updates that can be lost or misunderstood.

The feature is especially useful for multi-step repairs or inspections that span multiple shifts. A technician who begins troubleshooting a complex fault can leave detailed notes and recommendations for the next technician, who can then review the full history before continuing.

Improved continuity, reduces guesswork, and ensures everyone involved has access to the same information.

Building a culture of collaborative with CMMS

Collaboration in maintenance comes down to creating a shared framework where teams can plan, execute, and learn together. When managers use CMMS tools to align assignments, technicians use mobile access to stay connected in the field, and supervisors rely on historical data to guide decisions, the result is a more coordinated, accountable, and resilient maintenance operation.

Building this culture takes intention. It requires leadership to prioritize transparency, teams to adopt consistent documentation practices, and everyone to engage with the system as a central source of truth. Over time, these habits strengthen trust, reduce inefficiencies, and support continuous improvement.