With the ongoing global shortage of skilled technicians, facility managers need to invest in ways to attract and then retain talent. An important part can be educational opportunities, and companies that offer structured training programs for new technicians see a 40% reduction in first-year turnover, according to the 2025 SHRM Talent Trends report.

Just as important as providing the right training, though, is arming techs with the right tools. Facility managers can leverage key features in technician apps to speed up and strengthen onboarding for new maintenance staff, helping them hit the ground running.

What are the costs connected to training new maintenance staff?

The average cost of training a new employee in North America ranges from $954 to $1,252, with an average of 33 to 57 hours of training time. However, these numbers often reflect only the direct costs —including training materials, software, and instructor fees — without accounting for the broader operational impacts. The true cost of onboarding is usually higher, especially for more technical and hands-on roles. For example, new employees typically operate at only 25% productivity during their first month, and it can take up to 26 weeks for them to reach the required performance levels.

For field technicians and maintenance staff, often the largest hidden cost is time. During the onboarding period, seasoned staff must spend time supervising, mentoring, and double-checking new technicians’ work. Because the additional responsibilities pull them away from their own work, overall team efficiency falls while labor costs rise.

How do technician apps help facility managers train new maintenance staff?

The training benefits of technician apps start early in your workflows, where you have complete control over work orders, including approving, generating, assigning, and tracking work orders to ensure new hires work on tasks that match their current knowledge and abilities. For example, a new technician might start with basic tasks like changing printer ink cartridges in an office and gradually progress to more advanced tasks like troubleshooting HVAC issues.

Once you’ve assigned a work order to a new technician, they can leverage many of the app’s features to work quickly and correctly.

Asset tracking

Before a new tech can start working on assets and equipment, they need to find them, which can be a challenge when they’re trying to navigate through unfamiliar areas. The problem is compounded when they must work on one of in a long row of similar assets, for example one unit in a bank of pumps.

In a government building, for example, a new technician can use the app to find the exact location of a malfunctioning HVAC unit, ensuring they can start the repair process without delay. This feature is particularly useful in large, complex facilities where assets can be spread across multiple floors and rooms. In the manufacturing industry, asset tracking can be used to monitor the location and status of machinery on the factory floor, helping new technicians quickly locate and service equipment as needed.

Asset information and documentation

Because most require specific types of maintenance, parts, and materials, it can be challenging for new tech to work with unfamiliar assets and equipment. Using the app, they can scan asset tags or barcodes to retrieve detailed documentation, including model numbers, and user and repair manuals.

For example, a new technician at a large school campus can scan a barcode on a projector to get its model number and user manual, which helps them understand the specific requirements and procedures for maintaining the equipment. Immediate access to information reduces the time spent on research and ensures that tasks are completed correctly. In the healthcare industry, this feature can be used to access detailed information about medical equipment, helping new technicians perform maintenance and repairs with precision and safety.

Maintenance and repair histories

New techs lack the tribal knowledge that helps them quickly diagnosis issues and find fixes. Using the app, technicians can quickly access asset histories for a fuller picture of what went wrong in the past and how the team dealt with it.

On a construction site, for example, the new technician can review past work orders for a crane to understand the types of maintenance it typically requires, including lubrication and safety inspections. They can also use these histories to identify patterns and trends, which can inform preventive maintenance strategies and reduce downtime.

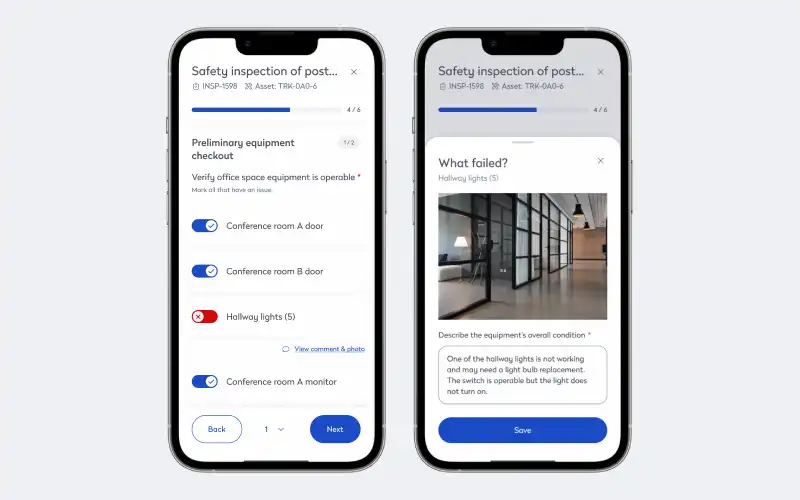

Comprehensive checklists

Establishing best practices for the team is only the first step. Next, you need to make the rules instantly accessible. Checklists for safety and regulatory compliance can guide new technicians through the necessary requirements, ensuring they follow all the safety protocols and regulatory standards, reducing the risk of accidents and legal issues.

In a healthcare facility, for example, a new technician can use a compliance checklist to ensure that all medical equipment is properly installed and that safety features are functioning correctly. In the energy sector, compliance checklists can help new technicians ensure that all safety measures are followed when working with high-voltage equipment, reducing the risk of accidents and ensuring regulatory compliance.

Step-by-step instructions

Technicians can use step-by-step guides for maintenance and repair procedures to correctly complete complex tasks. For example, a step-by-step guide for replacing a filter in an HVAC system might include detailed images of the filter’s location, the tools required, and the specific steps to follow. Because the techs can access them on-demand, they can refer to them whenever they need help while they’re in the field.

At a healthcare facility, for example, step-by-step instructions are crucial for ensuring that new technicians perform tasks accurately and safely. A new technician can use a step-by-step guide to clean and inspect medical equipment like an MRI machine. The detailed instructions help new technicians understand the importance of each step and build their confidence in performing these critical tasks. Because you can update the guides regularly to reflect the latest best practices and equipment changes, you can also ensure that new techs are not learning old bad habits from other staff.

Modern technician apps for better onboarding

Training new maintenance technicians is costly and time-consuming, involving both direct expenses and broader operational impacts. The largest hidden cost is often the time senior technicians spend supervising and mentoring new hires, pulling them away from their own tasks and increasing labor costs. Modern maintenance apps deliver key features including asset tracking, detailed documentation, maintenance and repair histories, comprehensive checklists, and step-by-step instructions, which help new techs perform tasks correctly and confidently. By leveraging these apps, facility managers can reduce onboarding time and improve the overall productivity and efficiency of their maintenance teams.