Idle time is when an asset or equipment is not in use, despite being available for production. It can be because of breakdowns, delays further up in the line, or maintenance. While some idle time is inevitable, too much impacts productivity, efficiency, and profitability. By looking at its causes, you can find practical, reliable ways to reduce it.

What is idle time?

Idle time is when your people and assets are ready, willing, and able to work but they aren’t. One way to think of “idle” is as the opposite of productive. When they’re idle, your team could be producing, but they’re not.

So initially, idle time looks a lot like downtime. But there are crucial differences, and they’re related to the reasons behind the lack of productivity.

Idle time vs scheduled downtime vs unscheduled downtime

With idle time, people and assets could be working instead of sitting idle. But with downtime, productivity is not even possible.

During scheduled downtime, the assets are offline because the maintenance team is working on them as part of the scheduled preventive maintenance program. They might be performing visual inspections, checking fluid levels, calibrating sensors, or adjusting alignments.

During unscheduled downtime, it’s the same result but for a different reason. Now, the maintenance team is working on the asset due to a failure. Here, they could be replacing a blown gasket, swapping out broken parts, or sealing a leak.

Examples of idle time

On the factory floor, a piece of equipment sits idle while the equipment in front of it in the production line is finishing. For example, the machine that inserts and tightens bolts can’t run until the machine that drills the required holes is done.

But you can also have idle time for people. In the front office, idle time is when an employee is waiting for the copier to warm up or for that quarterly report PDF to download from the company servers.

Specifically for a maintenance technician, they could be idly waiting for someone else to finish before they can start. So, if a maintenance supervisor needs to lock out and tag out an asset before the tech can work on it safely, while the supervisor is working, that maintenance tech isn’t.

Common causes of idle time for assets and equipment

The definition of idle time raises an obvious question: If they’re ready, willing, and able to be productive, why are the organization’s people and assets sitting idle? The answer is that they’re waiting. In fact, you can usually use “waiting time” and “idle time” interchangeably.

But what’s behind the waiting?

In some cases, idle time is built into the process. In the example of the machines that drill holes and insert screws, the first machine must finish before the second one can start.

In others, it’s a temporary operational interruption. For example, you might be better at producing a product than distributing it in the middle of a snowstorm. Here, you need to idle your production line once the warehouse is full of products waiting to be shipped. Or, if a local flood knocks out the electricity, your assets sit idle until the power comes back on.

In still other cases, idle time comes from poor overall maintenance practices. When an asset goes offline without warning, every other asset up and down the line goes idle. They’re not broken, but they’re not working.

Think of it this way: When you neglect to check the tire pressure on your car, eventually leading to a flat, you only need to repair the tire, but until you do, the whole car sits idle. You might have a tank full of gas and a perfectly tuned engine, but you’re not going anywhere. This is especially frustrating if you’ve invested good money in all the other parts of the car. Because of that flat tire, you’re not seeing any return on your various investments.

Formula to calculate idle time

It’s a simple formula once you have the right numbers. Take the scheduled production time and subtract the actual production time. The difference between those two numbers is the idle time.

For example, if you scheduled an asset to run for eight hours but in the end only ran for seven and a half, you had 30 minutes of idle time.

It depends on your industry, but in many cases, these numbers are not surprising. It takes time to start the machine up and get everything ready. During the shift, the asset might sit idle waiting for raw material or partially processed parts from earlier in the production line. There could have been a shift change or the operator may have quickly taken the asset offline to clean or adjust.

We can jump back to the car analogy to get a better understanding of how this works. Looking at a map, you can chart out how long it should take you to get from Point A to B. All you do is look at the distance and your estimated average speed.

But it’s always going to take you a bit longer to get there. You need time to get out to the car and start it up. Along the way, there are traffic lights and stop signs. There might even be detours. Worst case, you make an unplanned stop for gas along the way. Then when you arrive, you still need to walk from the parking lot to your destination, which also takes time.

How can you reduce idle time?

The first step to success is setting the right goal, and here that means understanding that you can never eliminate idle time. There are always factors out of your control. And there are always good reasons for assets to sit idle. In the end, you want operators to keep a steady schedule of cleaning, adjusting, and double-checking that everything is set up correctly. You must be able to schedule breaks and bring in new operators, so no one works 18 hours a day.

That said, when your idle time is a direct result of poor planning or execution, you can take steps to reduce it. Remember, looking at the strict definition of idle time, it’s the opposite of productivity. You could be meeting goals or even getting out ahead of them, but you’re not.

Here are some general steps you can take to reduce idle time.

Ask the right people the right questions

Who knows your facility best? The people who work there. When looking for ways to reduce idle time, talk with people up and down the organizational chart to find and fix the most common causes of slowdowns and delays.

In many cases, unclear work instructions can cause idle time as one section of the line struggles to understand exactly what they should be doing. Or it could be a confusing or incomplete bill of materials (BOM). You can think of a BOM as a sort of recipe for collecting and using the right combinations of parts to produce a product. While operators are busy wasting time working it out, everyone downstream from them sits idle.

In some cases, tool and inventory hoarding can cause idle time. Here, one group of employees dominates the use of the available tools and parts, even ones they don’t currently need, preventing others from completing their tasks. The solution could be to buy more tools. You can also look at modern inventory control platforms to ensure teams have the parts and materials they need, right when they need them. Once you’ve removed the element of scarcity, people stop hoarding.

Chain efficient workstations with the right transit and cycle times

Start by looking at each workstation. Does it look like a surgical theatre with all the clean, working tools nicely laid out? There should be a logical order to where they are, and once you have a place for everything, everything should be in its place.

Once you have the workstations worked out, you can look at chaining them together for maximum efficiency. For example, if a part takes three minutes at Station A but only one minute at Station B, how does that affect Station C? Also, how much time does it take for you to move that part between stations? You need your individual stations set up properly and then carefully positioned in relation to one another to reduce part transit time.

Make sure to include safety considerations in any decisions you make about where to place stations and how you set them up. If part of the production line involves welding, for example, you would think about ventilation requirements before worrying about anything else.

How does asset management software help you reduce idle time?

And just like with those other parts of your operation, you can reduce idle time by improving your maintenance workflows. And at every step of the way, modern asset management solutions make everything faster, easier, and more reliable. The maintenance team gets more done for less money.

Capture hard-won know-how and standardize your standard operating procedures (SOPs) with templates

The first step was asking the right people the right questions, and here, too, it pays to talk with the experts: the people performing maintenance on your assets and equipment.

The problem: A lot of maintenance teams run too much key person risk, where losing one or two technicians shuts down the rest of the team. The problem is that all the critical knowledge of how the assets run and how to repair them is trapped inside the heads of a few members of the team. Lose them to job changes or retirement, and all that knowledge walks out the door with them.

The solution: Move all that hard-won maintenance know-how into a CMMS solution where it’s safe, secure, and accessible. For all your most important and most common maintenance inspections and tasks, the team builds out templates packed with step-by-step instructions and checklists. Now, with just a few clicks, all this information can be added to digital preventive maintenance and on-demand work orders.

The advantages: The maintenance team can fix things faster and better because they’re following best practices. And things tend to stay fixed when the techs use the right tools and techniques.

That sort of consistency is helpful even when technicians are consistently wrong. When the team must go back and troubleshoot a repair, it’s easier for them if everyone did the same work the same way. Because there are fewer variables, it’s easier to track down the problematic process and update it.

Set up, schedule, and track a preventive maintenance program than cuts downtime

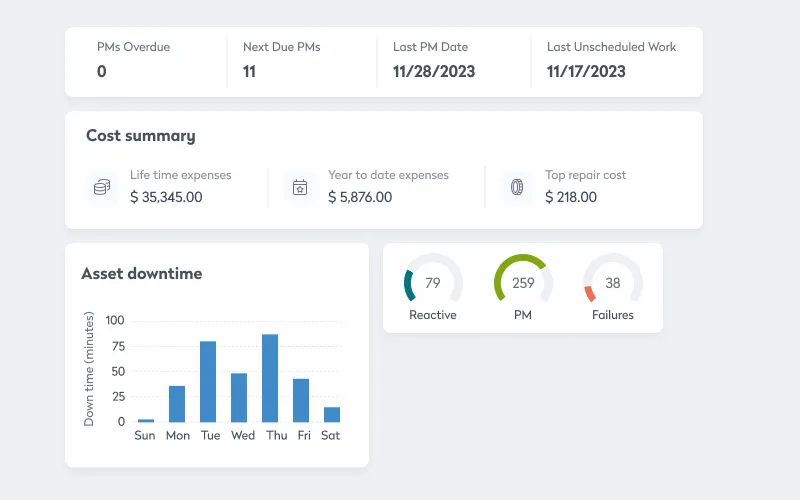

While it’s true that downtime is different from idle time, the two are connected. When Asset A goes offline unexpectedly, Assets B through Z are suddenly sitting idle. Less unscheduled downtime means less idle time.

With a preventive program the maintenance team can easily set up, schedule, and track, they can find and fix small issues before they have a chance to grow into expensive problems that shut down the line, forcing all the other assets to become idle.

But it’s more than just finding and making small fixes. With preventive maintenance, the maintenance department schedules everything in advance, and that means they can choose to do work on assets and equipment when it’s the least disruptive. Instead of making emergency repairs in the middle of a shift, they can work on assets and equipment between production runs.

And because they know the required tools, parts, and materials ahead of time, they arrive already prepared with everything they need to work quickly. For example, the maintenance team knows it’s going to test and add lubricant to a critical motor next week. Today, they double-check the parts and materials inventory and discover they need more lubricant. Because they can send out the purchase order a week in advance, everything arrives before the team needs it.

By moving away from the inefficiencies of on-demand repairs, you save the team from the frustration of not having what they need when they need it, as well as the costs of both a rush delivery and an idle production line.