The continuing global shortage of skilled technicians will make it more challenging to properly manage assets while also controlling labor costs. As demand drives up wages while lowering requirements, maintenance departments could be paying more for less qualified staff. By investing now in the next generation of skilled trades and the technicians already on staff, maintenance leaders can continue to deliver efficient, productive facilities.

Understanding the maintenance technician shortage

The ongoing shortage of maintenance technicians is a multifaceted issue driven by both demographic shifts and cultural changes. As the older generation of technicians retires, the younger generation’s overall interest in entering the trades has waned. Even if the number of new technicians entering the field matched the number of those leaving, the decades of experience and specialized knowledge possessed by senior technicians are difficult to replace.

Demographic shifts

According to the Bureau of Labor Statistics, approximately 160,100 openings for general maintenance and repair workers are projected each year, on average, over the next decade. Many of these openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as retirement. The largest factor in this trend is the retirement of the Baby Boomer generation. They had been steadily leaving the workforce for years, but the pace accelerated during the pandemic. By mid-2020, nearly 30 million Baby Boomers had retired.

Cultural changes

The difficulty in replacing maintenance technicians is further compounded by cultural shifts. Historically, Baby Boomers have encouraged their children to pursue university degrees rather than trade school or apprenticeship programs, which has led to a significant increase in the number of individuals pursuing four-year degrees and a corresponding decrease in those entering the trades.

The decline in school shop classes has also played a role. These classes once provided young people with their first exposure to the trades, sparking interest in fields such as welding and automotive repair. There are several theories as to why schools stopped offering shop classes, including the emphasis on standardized testing and the allocation of funding based on academic performance incentivizing schools to focus primarily on improving math and language scores, at the expense of vocational training. Some recent reports suggesting shop classes are coming back and young people are going into the trades instead of university, but maintenance teams won’t see the benefits for years.

Solving the maintenance technician shortage

In the same way that there’s more than one reason behind the shortage, you need more than one solution. While some involve more long-term investments, there are steps facility and maintenance leaders can take for more immediate results.

Invest in the next generation of facility and maintenance professionals

Facility and maintenance professionals can help aspiring and young techs in a variety of ways, including in-house efforts and industry events.

In episode 134 of the Asset Champion podcast, Ilana Dunoff, a consultant and adjunct professor at Temple University, emphasizes that preparing these techs involves fostering a strong, supportive work culture and promoting continuous learning and adaptability. She highlights the importance of maintaining a cohesive company culture, especially in the face of remote and hybrid work models and suggests strategies like “coffee and culture” to encourage human connection and collaboration. She encourages organizations to help young techs find work-life balance, provide ongoing education and credentialing, and create spaces for conversation and connection, ensuring they are well-equipped to navigate the dynamic and ever-changing landscape of facility management.

FM Pipeline is an organization dedicated to engaging, enlightening, and energizing the next generation of facility management (FM) professionals. They host the Facilithon, a unique competition designed to introduce high school and technical school students, along with their advisors, to careers in FM. The event includes a 50-question common-sense quiz, a 10-minute FM role play, and challenge, which simulates an FM emergency.

Support ongoing professional development for current technicians

The effects of the shortage are industry wide, but companies can reduce their exposure by holding on to the technicians they already have. As it becomes more difficult to replace technicians, retention becomes more important.

Educational opportunities can be an important part of these efforts. 45% of employees are more likely to stay in their role if they receive more training, according to a report from Built In, while 94% of employees say they won’t quit if they get development opportunities, according to LinkedIn’s 2023 Workplace Learning Report. By prioritizing training, companies can create a supportive and growth-oriented environment that keeps workers engaged and loyal, ultimately enhancing overall performance and stability.

There are currently many different options for maintenance technicians looking to acquire or update their skills sets, including:

- Certified Maintenance & Reliability Technician (CMRT): The Society for Maintenance and Reliability Professionals (SMRP) manages this comprehensive certification covering general maintenance management, maintenance practices, preventative and predictive maintenance, troubleshooting and analysis, and corrective maintenance.

- Certified Maintenance & Reliability Professional (CMRP): SMRP also has a certificate for business and management, equipment reliability, manufacturing process reliability, organization and leadership, and work management. It’s accredited by the American National Standards Institute (ANSI).

- Certified Plant Engineer (CPE): Association for Facilities Engineering (AFE) delivers training and certification for facility maintenance, electrical, civil, and mechanical engineering, OSHA safety, and energy management.

Canadian Manufacturers and Exporters offers a wide range of certificate programs and workshops.

Implement a modern intelligent asset management solution

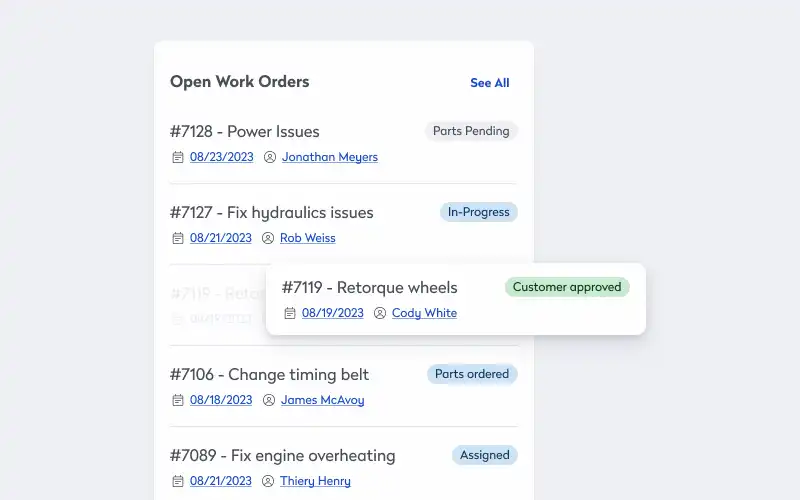

Companies that implement digital, integrated asset management can more easily retain employees by offering a modern, professional, organized, predictable, and safe workplace.

Enhanced job satisfaction and professional growth

Modern intelligent asset management technology can greatly improve job satisfaction for maintenance technicians. These tools simplify maintenance processes, reduce manual labor, and provide real-time data that helps technicians make better decisions. By automating routine tasks and offering advanced analytics, intelligent asset management systems allow technicians to focus on more complex and interesting work, which is often more rewarding.

Using advanced technology also opens new career paths and opportunities for growth. Technicians who are skilled with these systems can take on roles that require higher technical expertise, such as data analysts, system administrators, or technology consultants, making their jobs more dynamic and challenging, increases their value to the company, and leads to better job security and higher pay. Companies that invest in modern technology and provide training are more likely to keep top talent, as these professionals see a clear path for advancement and development.

Improved work environment and safety

Intelligent asset management technology can create a safer and more efficient work environment for maintenance technicians. By integrating IoT sensors and predictive maintenance algorithms, maintenance teams can use these systems to detect potential equipment failures before they happen, reducing the need for emergency repairs and minimizing the risk of accidents. A proactive approach ensures that technicians are not constantly under pressure to fix unexpected issues, which can lead to burnout and job dissatisfaction.

Modern asset management systems often come with features that enhance workplace safety, such as automated work order generation, real-time monitoring of hazardous conditions, and compliance tracking. These tools help ensure that maintenance tasks are performed safely and efficiently, reducing the likelihood of workplace injuries. A safer work environment not only protects the well-being of technicians but also fosters a positive company culture where employees feel valued and supported. This can lead to higher job satisfaction and a stronger sense of loyalty, making it easier to attract and retain skilled professionals.

Intelligent asset management supports roles across the enterprise

Modern asset management software benefits many teams within a large company. It automates day-to-day operations, enhancing operational efficiency and reducing costs by freeing up technicians’ time to focus on critical tasks and minimizing operational overhead. It also provides greater visibility over assets, enabling teams to manage equipment lifecycles effectively and reduce downtime, which can be significantly more expensive than planned maintenance. It also supports regulatory compliance and enhances workplace safety through compliance checklists and inspection failure resolution, ensuring that assets are maintained according to standards and safety issues are addressed promptly. Collectively, it helps teams maximize asset utilization, lower repair costs, and improve overall performance.

Learn how to get more from your assets.