Maintenance reliability is “the probability that a component or system will perform a required function for a given time when used under stated operating conditions.” But what does that mean? And more importantly, what does it mean for the facility and maintenance teams?

What is reliability?

The definition is long, and it’s important to understand each of the parts and how they interconnect.

the probability that a component or system

Reliability is a measurement of asset and equipment performance. You can also use it to measure the performance of specific parts inside those assets and pieces of equipment. So, for example, you can measure reliability for an entire car or just the motor that drives the pump for the window washer fluid.

Reliability is connected to probability, which means it’s a way of answering the question “What are the chances?”

will perform a required function

On the most basic level, it’s about the asset or equipment working the way we want it to. It’s not failing, and that covers both complete and partial failures.

Remember, there are different ways to fail. A complete failure is when your car is sitting at the side of the road with a flat tire. And a partial failure is when the engine timing is off, affecting performance. In some cases, you can fail “silently.” For example, you might have a piece of equipment on the production line spitting out tin cans that are the wrong shape without anyone noticing.

for a given time

When we calculate reliability, we need to factor in time. In fact, one way to think about reliability is how long you can trust an asset to run before it fails.

And a basic formula for calculating reliability is the hours of operation divided by the number of failures, which is the basic formula for mean time between failures (MTBF).

If we’re looking at something’s reliability over time, the formula becomes more complicated, but time is still a big part of it.

when used under stated operating conditions

How reliable is your car if you only ever drive it to and from work five days a week for a month? That’s one calculation. But what if you drive the same route the same number of times in a month but now at ten times the average speed?

The reliability you first calculated no longer applies. As soon as you change the operating conditions, you must rethink reliability.

And that can be a huge issue for your maintenance department if the front office decides to improve their return on investment on assets by running them longer and/or harder. So, that reliable pump that’s only ever been cycling a thousand times a day is going to start failing a lot more often when it’s pushed to two thousand cycles a day after the front office adds a second shift to the production schedule.

Can you keep it running with the same level of reliability? Of course, but you first need to rethink the maintenance program you’re running for that asset, including frequencies for all your inspections and tasks.

What is the difference between reliability and availability?

That’s likely the more common question, but it might be more helpful to ask, “What is the connection between reliability and availability?”

The connection is that availability is a function of reliability, and the two have a direct relationship. What this means is that because reliability can be a part of the formula you use to calculate availability, the better your reliability, the better your availability. That direct relationship means that when you increase reliability, you also increase availability.

In fact, you can think of reliability as sugar and availability as a glass of water. How sweet is your availability? The more reliability you add, the sweeter your availability.

That’s the relationship between the two. But getting back to the original and more common question, what are the differences?

Just like with reliability, availability is also related to probability. It’s a way of answering the question “What are the chances?” But here you’re looking at a different “chances of what.”

Availability is the probability an asset or piece of equipment is available when you need it. So, you take the actual working time and divide it by the scheduled working time. Then take that result and multiply it by 100 to get your availability as a percentage.

Someone scheduled an asset to be running for 100 hours. At the end of the 100 hours, though, you know the asset was up for 89 hours. Eighty-nine divided by 100 is .89, and that multiplied by 100 is 89%. In a perfect world, you’d see 100 hours of uptime for every 100 hours of scheduled time. But in the real world, you can aim for 90% as a reachable goal.

When trying to establish your uptime, remember to subtract both scheduled and unscheduled downtime. If an asset fails halfway through a production run, and it takes the maintenance techs an hour to get it back online, that pulls the availability percentage down.

But when that same asset is offline for an hour because you scheduled a set of inspections and maintenance tasks as part of a preventive maintenance program, the effect on the availability percentage is the same. Downtime, for any reason, has a negative effect on your availability.

The good news is that you now have two ways to improve availability. The first is by scheduling preventive maintenance inspections and tasks so they don’t interrupt production. Instead, you can schedule PMs for when you already know the asset is set to be offline. For example, in between shifts or production runs.

The other way is by increasing reliability.

How can you improve maintenance reliability?

The answer depends on where you are right now.

If you already have facility management solution and a robust preventive maintenance program packed with inspections and tasks (PMs) you’re able to set up, schedule, and track with reliable data, it could be time to start looking at implementing reliability centered maintenance (RCM). Here, you’re doing detailed failure mode analysis and then using those insights to match each asset to one of the four main maintenance strategies to maximize uptime. In some cases, you might find you need to implement condition-based maintenance, which involves high-tech sensors and complex algorithms.

But if you’re still trying to manage work orders with old-fashioned manual methods, your first step should be implementing a facility management platform. With modern solutions, your data lives in the cloud, so it’s safe, secure, and always accessible from any Internet-connected device. And because everyone on the maintenance team is working from the same data, everything is up to date.

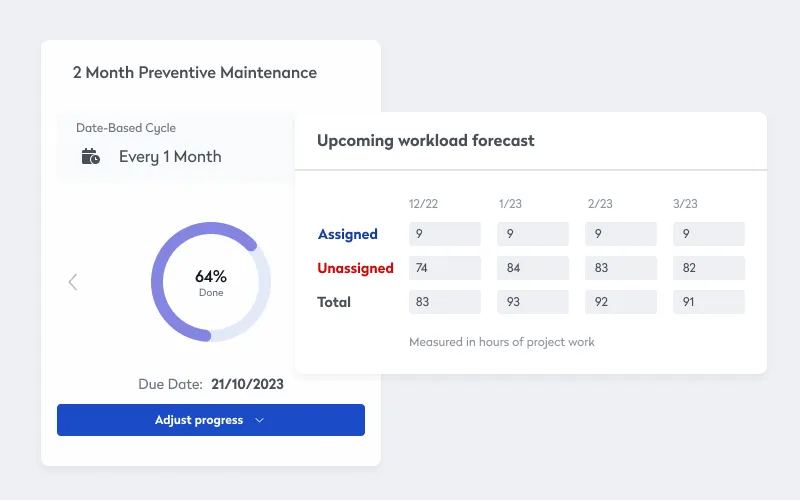

With the right unified solution, it’s now also a lot easier to set up, schedule, assign, and track preventive maintenance work orders. Using templates, you can add detailed instructions and checklists in just a few clicks. From the calendar dashboard, you can schedule new PMs or reschedule existing one with drag and drop. You even have a choice of PM types, including floating and fixed or time- and meter-based ones.

Once you’re ahead of the maintenance curve, you can find and fix small issues before they have a chance to snowball into big problems. And because now more of your work is inspections and small adjustments, everything takes less time. Downtime goes down, while uptime increases.

The result is you can increase the overall reliability of your assets.