Across industries like manufacturing, transportation, energy, and public infrastructure, enterprise asset management (EAM) software is a strategic tool for facility and maintenance teams focused on delivering the strongest possible return on investment (ROI). By centralizing asset data and streamlining maintenance workflows, EAM helps organizations reduce operational complexity, improve asset reliability, and support long-term planning. The result is a more proactive, efficient approach to managing physical assets throughout their life cycle.

Key takeaways

- Enhanced uptime and reliability: EAM software not only helps in scheduling preventive maintenance but also uses predictive analytics to flag potential issues before they become critical, ensuring assets remain operational, reducing downtime and maintaining service quality

- Optimized life cycle management: By providing detailed life cycle tracking, EAM software enables organizations to make data-driven decisions about asset repairs, replacements, and upgrades, helping extend the useful life of assets and maximizing their value over time

- Improved workforce productivity: EAM platforms streamline task assignments and provide mobile access to work orders, reducing administrative overhead and enabling technicians to focus more on maintenance tasks, supporting faster response times, fewer missed tasks, and higher team morale

Beyond operational efficiency, EAM software empowers organizations to align maintenance practices with broader business goals. With improved visibility, smarter resource allocation, and data-driven insights, teams can unlock performance and profitability.

Understanding ROI drivers in facility management software

When looking at EAM software, it’s important to understand the core ROI drivers, the specific areas where modern platforms deliver measurable value in operational efficiencies that control costs.

Uptime: Keeping operations running smoothly

Uptime is the percentage of time assets and systems are operational and available. In mission-critical environments like government facilities, manufacturing plants, and construction sites, even minor unscheduled downtime can disrupt services, delay projects, or compromise security.

EAM software helps teams maximize uptime by transforming maintenance from a reactive process into a proactive strategy, including preventive and predictive approaches.

To support uptime and reduce unnecessary service, EAM platforms offer a range of tools designed to keep operations running smoothly, including:

- Automated scheduling to ensure timely preventive maintenance

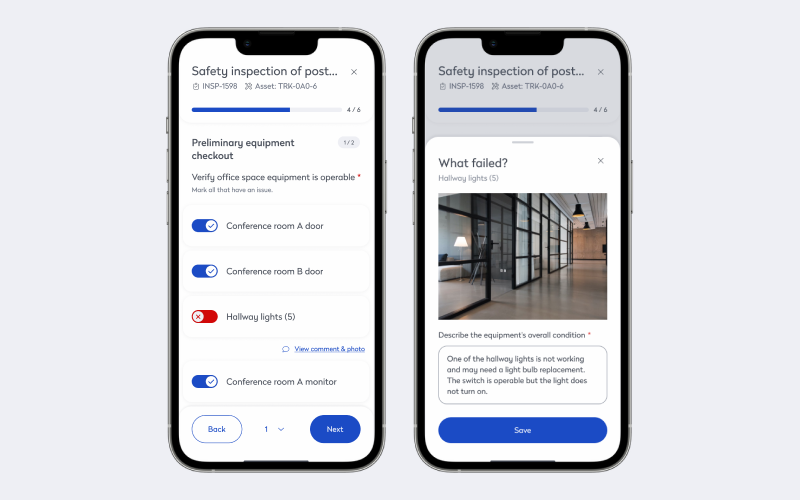

- Mobile technician apps for real-time updates and task management in the field

- Failure code tracking to identify recurring issues and improve diagnostics

- Inspection checklists to standardize procedures and ensure compliance

These capabilities help teams avoid breakdowns, streamline maintenance workflows, and maintain asset reliability across the organization.

For example, you might be managing a public transit facility where HVAC systems are critical to rider comfort. One morning, the EAM dashboard flags a unit showing abnormal temperature readings. Instead of waiting for a complaint or a full failure, your technician receives a mobile alert, inspects the unit, and replaces a worn belt before it causes a shutdown.

Riders stay comfortable, and your team avoids an emergency repair. Meanwhile, other units continue to receive scheduled preventive maintenance to ensure long-term reliability.

Life cycle tracking: Extending asset value

Tracking assets ensures teams can actively monitor assets, from acquisition to retirement. Increased visibility allows organizations to make informed decisions about repairs, replacements, and upgrades based on performance data and cost analysis.

In industries like utilities or agriculture, where assets are distributed across large geographic areas, centralized life cycle tracking helps identify underperforming equipment and prioritize investments. Leaders can compare usage patterns, maintenance history, and downtime metrics to determine which assets deliver the most value.

EAM platforms support life cycle optimization through features like asset registries with parent-child hierarchies, depreciation tracking, document management, and lifecycle cost dashboards. These capabilities help align capital planning with actual asset performance, avoiding premature replacements and ensuring every dollar spent contributes to long-term profitability.

For example, you might oversee a regional airport. Your EAM system shows one baggage conveyor has required frequent repairs over the past year, while others of the same age are performing well. You dig into the history and discover it was installed with a misaligned motor. With this insight, you schedule a targeted upgrade and adjust future installation protocols, extending asset life and improving reliability.

Compliance: Maintaining regulatory and security standards

Compliance is critical in government environments, where agencies must meet strict standards for data protection, accessibility, and operational integrity. EAM platforms support compliance by automating inspections, tracking certifications, and documenting safety procedures.

In highly regulated sectors like energy, transportation, and healthcare, these features help ensure assets meet safety standards and personnel are properly trained. Automated alerts and digital checklists reduce human error and improve accountability.

So, when you’re managing a network of public health clinics, your EAM system automatically schedules monthly inspections for emergency generators and tracks technician certifications. During a surprise audit, you pull up digital records showing the team completed every inspection on time. The auditor is satisfied, and your facility passes without issue.

Cost visibility: Making smarter financial decisions

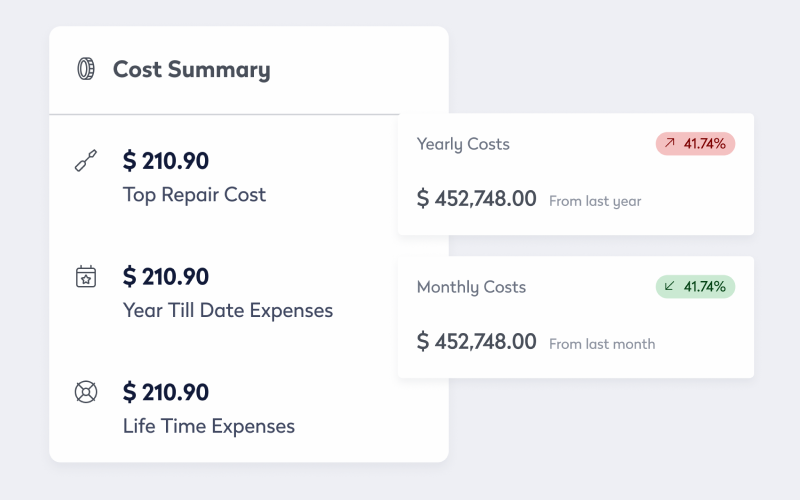

Cost visibility means having a clear picture of where you’re spending and where you could be saving. Facility management platforms provide dashboards and reports that show maintenance costs by asset or location, energy usage trends, and labor allocation, including overtime.

Transparency allows agencies to optimize budgets, reduce waste, and justify investments with data-backed insights. For example, finance teams can use asset utilization data to refine budgets and forecast future needs, while facility managers can identify high-performing sites and replicate their success.

Analytics features like customizable dashboards, utilization tracking, forecasting tools, and integration help organizations move from reactive to proactive planning, ensuring every decision is backed by data and aligned with larger business goals.

For example, you might be overseeing a portfolio of government office buildings. One site consistently exceeds its energy budget. Your EAM platform reveals the building’s HVAC system runs overnight due to outdated scheduling. You adjust the settings, monitor the impact, and see a noticeable drop in energy costs, freeing up budget space for other priorities.

Workforce efficiency: Empowering teams to do more

When technicians, managers, and support staff have access to the right tools, they can complete tasks faster, collaborate more effectively, and reduce administrative overhead.

EAM platforms improve workforce efficiency by streamlining task assignments, enabling mobile access to work orders, and automating routine processes. These features help reduce delays, eliminate paperwork, and ensure everyone stays informed and aligned.

With mobile work order management, role-based dashboards, task automation, and technician location tracking, teams stay productive and responsive, especially in large or distributed environments.

For example, you manage maintenance for a university campus, and before implementing an EAM, your technicians spent hours each week returning to the office for paper-based work orders. Now, they receive assignments on their phones, log work in real time, and upload photos for documentation. You see faster response times, fewer missed tasks, and higher morale across the team.

Success story: Driving operational efficiency at MDL with Eptura™ Asset

Maritime Developments Ltd. (MDL), a global leader in subsea equipment manufacturing, operates in some of the harshest offshore environments. With over 1,000 high-value assets, including cable lay tensioners and reel drive systems., MDL needed a smarter, more scalable way to manage maintenance and reduce costly downtime across its operations.

MDL’s maintenance team was trying to rely on manual, reactive processes. Technicians spent hours entering data into spreadsheets after offshore projects, which slowed operations and increased the risk of errors. The lack of centralized visibility made it difficult to track asset performance, prioritize tasks, or plan preventive maintenance effectively, especially for complex mechanical, electrical, and hydraulic systems.

To modernize its maintenance operations and reduce inefficiencies, MDL implemented Eptura’s EAM platform. The solution offered a suite of integrated tools that addressed the company’s most pressing challenges and supported its shift toward proactive maintenance.

Real-time visibility into more than 1,000 assets

MDL manages a large and diverse fleet of offshore equipment, each with unique maintenance needs. Eptura’s platform provided centralized, real-time visibility into the status, location, and performance of over 1,000 assets, allowing the team to monitor conditions across facilities, identify issues early, and make informed decisions without relying on manual data entry or fragmented spreadsheets.

Predictive and preventive maintenance tools

Instead of reacting to breakdowns, MDL now uses predictive analytics to anticipate failures before they occur. The system schedules preventive maintenance based on usage patterns, wear indicators, and historical data. The shift has helped reduce unplanned downtime and extend the lifespan of critical equipment, ensuring that offshore operations remain safe and efficient.

Centralized data management for smarter decision-making

Previously, maintenance records were scattered across paper forms and spreadsheets, making it difficult to track asset history or analyze performance trends. Eptura’s centralized data system consolidates all maintenance activity, work orders, and inspection results into a single platform. This enables MDL to identify recurring issues, optimize resource allocation, and plan long-term maintenance strategies.

Since implementing Eptura, MDL has seen measurable improvements across its maintenance operations, including a 20% reduction in unplanned maintenance and more than eight hours saved per technician on post-project data entry.

“What we can do now in Eptura is see statistics, analytics, and insights into any asset and see the maintenance history. With a click of a button, we can get a nice Power BI presentation of that asset. The system shows us how reliable that asset is being over time, what components are wearing out more than others, and we can make a far quicker decision on any obsolescence,” explains Sean Burrows, technical coordinator at MDL.

To discover all the ways MDL improved operations by implementing Eptura, read the full success story.