The CHIPS and Science Act promises transformative growth and innovation within the semiconductor industry in America, but it also highlights the existing challenges for manufactures. Building new facilities is expensive, and the manufacturing processes are highly technical, so businesses struggle to staff their lines. Through direct funding and tax breaks, the Act aims to lower the barriers to entry for new construction and expansions while also investing in STEM fields to develop the future workforce.

But the Act can’t do it all alone. Once the facilities are online, companies will need to meet complex compliance goals and attract and retain talent. Industry leaders can leverage advanced facility management software to meet these critical needs. A modern unified platform enhances operational efficiency, ensures regulatory compliance, and improves the overall employee experience to help enterprises attract and retain talent.

What is the CHIPS and Science Act?

Over the last few decades, microchip manufacturing has steadily moved outside the United States. In 1990, America produced close to 40% of the world’s supply. Currently, it accounts for less than 10%. Taiwan now leads global output, manufacturing more than 60% of all semiconductors and more than 90% of the most advanced chips, while America does not make any higher-end chips.

The Creating Helpful Incentives to Produce Semiconductors (CHIPS) and Science Act of 2022 is how the US government plans to grow domestic semiconductor manufacturing, research, and development. The Federal government has allocated over $52 billion in funding to support the industry, which supplies critical components for everything from consumer electronics to national security. The government wants to reduce the country’s dependence on foreign chip manufacturing, which has caused concern because of global supply chain disruptions and geopolitical tensions.

To bring production back to America, the Act specifically focuses on increasing domestic production capacity through helping the private sector build new facilities and expand existing ones, while also investing in science, technology, engineering, and mathematics (STEM) education.

Reshoring semiconductor manufacturing, a two-pronged approach

The Act directly facilitates the construction of new semiconductor manufacturing facilities through substantial financial incentives, including grants and tax incentives aimed at encouraging domestic production. In fact, there’s $39 billion for the CHIPS for America Fund to build new and expand existing semiconductor facilities, and companies can also apply for a 25% tax credit. The hope is to leverage strategic funding to attract private investment.

By supporting the construction of state-of-the-art facilities, the Act not only aims to increase the domestic production capacity of semiconductors but also ensure that these facilities are equipped with the latest technology for efficient manufacturing to help the country maintain technological leadership and meet the growing demand across sectors, including defense, healthcare, and information technology.

In addition to financial incentives for semiconductor production, the Act also includes provisions to foster education and workforce development in the STEM fields. By investing in the next generation of scientists, engineers, and researchers, the government hopes to increase its leadership in innovation by building a robust ecosystem that supports discoveries and development.

By many metrics, so far the Act has been a success. Chipmakers have set aside billions of dollars to build new plants. Intel has new factories in Arizona and has broken ground on fabs in Ohio. Taiwanese chipmaker TSMC has a $40 billion expansion in Arizona, making it among the largest foreign investments in US history. Boise-based Micron also has plans for a new plant.

What are the main challenges for US-based semi-conductor manufacturing?

One of the biggest challenges for US-based semiconductor manufacturing is the high cost of building and maintaining capacity. The facilities, which the industry calls fabs, can cost between $5 billion and $20 billion — more than what it costs to build a nuclear power plant — because of the sophisticated equipment and tightly controlled environments necessary for production. Even with a lot of support from the government, substantial initial capital outlay can be a significant barrier to entry, making it difficult for new players to enter the market and for existing companies to expand.

They take a lot of money to build, and then they take a lot of energy, water, and chemicals to run.

According to a recent Fortune report on the environmental effects of microchip production, “… large fabs can use as much as 100 megawatt-hours of power hourly, more than what oil refineries or automotive plants consume … Each semiconductor factory can also consume more than 1 million gallons of water daily, in addition to producing thousands of tons of chemical waste annually.” New manufacturing technology for high-end chips uses even more energy, can potentially produce more carbon emissions.

The industry is also facing a shortage of skilled workers due to the highly specialized nature of semiconductor manufacturing, which requires a workforce with specific technical skills and knowledge. Because this gap in skilled labor can hinder the growth and sustainability of semiconductor manufacturing, it is important to invest in education and training programs that can produce the next generation of engineers and technicians needed to support this critical industry.

How can chip manufacturers overcome these challenges with a unified digital facility management platform?

By implementing a modern technological solution, companies can optimize their operations, improve compliance, and foster a workplace culture that values well-being and efficiency, giving them competitive advantages in both talent acquisition and operational excellence.

Improve employee experience to attract and retain top talent

When the demand outstrips supply, companies are in direct competition for employees, and offering higher salaries is not enough to ensure staffing numbers. Companies must also offer the best possible employee experience.

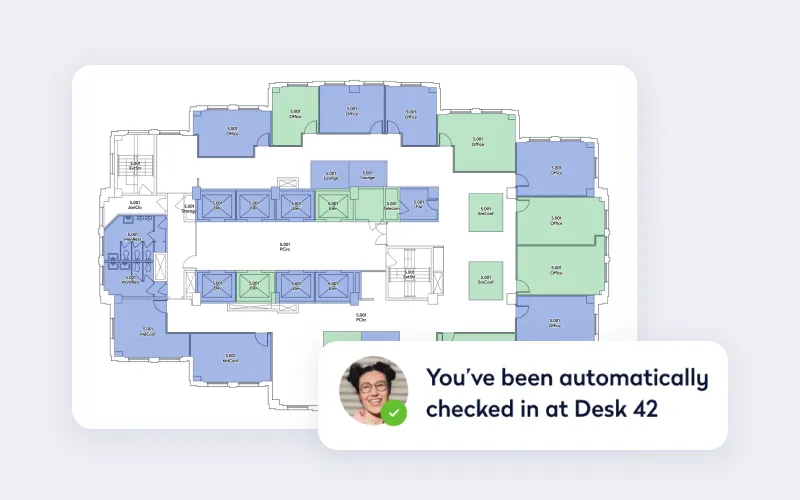

A workplace management software platform significantly enhances the employee experience by optimizing the physical workspace and streamlining communication, delivering efficient space management, ensuring that employees have access to the resources they need, including booking meeting rooms, desks, or other facilities. By facilitating a more flexible and adaptive work environment, the software supports different working styles and preferences, which can lead to increased satisfaction and productivity. It also integrates with other tools like calendars, making it easier for employees to collaborate and manage their schedules effectively, reducing stress and improving day-to-day operations.

For facility and workplace leaders, modern solutions also provide analytics and insights on how spaces are used and how they can be improved to better meet employee needs. A proactive approach not only optimizes the use of the workplace but also shows employees that their well-being and comfort are valued. As a result, employees are likely to feel more engaged and connected to their workplace, fostering a positive organizational culture that attracts and retains top talent.

Implement a digital environmental health & safety (EH&S) solution

EH&S software helps organizations manage and improve their compliance with environmental regulations, enhance workplace safety, and promote employee health by streamlining processes related to risk assessments, incident reporting, audits, and regulatory compliance, ensuring that businesses can effectively address potential hazards and maintain high standards of workplace safety and environmental stewardship.

The software can deliver many benefits, including:

- Compliance management: Ensures compliance with local, national, and international regulations by keeping track of changes in legislation and helping businesses adjust their practices accordingly.

- Risk assessment: Enables companies to conduct thorough risk assessments, identify potential hazards, and implement preventive measures to mitigate risks, reducing the chances of workplace accidents and environmental incidents.

- Data centralization: Centralizes data, making it easier to access and manage information related to health and safety, environmental performance, and compliance, enhancing transparency and accountability.

- Audit and inspection: Simplifies the scheduling and execution of audits and inspections, ensuring compliance.

- Waste management: Helps in tracking, managing, and reducing waste production, supporting sustainability initiatives and compliance with environmental regulations.

- Resource optimization: Improves process efficiencies and reduces the time spent on administrative tasks, helping companies to allocate resources more effectively.

- Reporting and analytics: Provides insights into performance, helping organizations make informed decisions to improve health, safety, and environmental management.

- Enhanced employee engagement: Connects employees to safety and compliance processes, providing a safer workplace and boosting morale and productivity.

These benefits collectively contribute to a safer, more compliant, and efficient operational environment, supporting the well-being of employees and the organization’s sustainability.

How Eptura helped AMD reach reporting on over 250 EH&S data points

Advanced Micro Devices (AMD) manufactures computer processors, including microprocessors, graphic processors and other semiconductor-based components for both consumers and businesses. The enterprise-level organization has 10,000 employees spread across a global portfolio of 39 facilities with a combined 2 million square feet.

The company has always invested in its commitment to the environment and employees. “AMD has a long legacy of promoting corporate responsibility in a number of areas as demonstrated by our 20 years of reporting, setting, and meeting environmental health and safety goals. We have been reporting on over 250 environmental health and safety data points …,” explains Julia Trimmer, Senior Manager, Health, Safety, Security & Environment Advanced Micro Devices.

To reach rigorous sustainability and compliance goals, AMD implemented a wide range of Eptura features, including:

- EH&S

- Energy management

- Portfolio management and lease administration

- On-demand work orders and preventive maintenance

- Space inventory and performance

- Personnel and occupancy

- Enterprise move management

Their investment has delivered concrete improvements. With comprehensive reporting, they’re able to monitor over 250 environmental health and safety data points. And they’ve hit renewable energy goals. For example, they achieved a 25% renewable energy use target and a 20% reduction in absolute greenhouse gas emissions. With better energy management, they optimized energy and utility spending to reduce unnecessary consumption and costs.

To learn more about how Eptura supports AMD’s success, read the complete customer success story.