Planned maintenance is a proactive approach to maintenance where you focus on minimizing the downtime and costs associated with breakdowns.

You start the process by identifying a maintenance challenge you want to address, such as reducing downtime or increasing the lifespan of your assets and equipment. You can then anticipate, schedule, and document the various tasks that help you reach your goal.

Regular inspections, parts and materials inventory control, process descriptions, and work prioritization are all part of the planned maintenance process. The frequency of those tasks depends on the asset you want to maintain and is based on measurable factors, including the number of items produced, equipment running time, and distance traveled. Once you’ve created a maintenance schedule, you must put the parts, materials, tools, and resources in place to ensure the team completes the work correctly and on time.

What are the different types of planned maintenance?

There are two types of planned maintenance that you can implement.

Planned preventive maintenance

Planned preventive maintenance (PPM) is the process of conducting regular, routine maintenance of your assets and equipment to prevent unexpected equipment failures and reduce costly downtime. Preventive maintenance uses industry standards and data insights to determine when you should perform maintenance tasks to prevent failures. You can trigger inspections and maintenance tasks based on usage, time, or condition-based factors.

Preventive maintenance can be an effective way to maintain assets with:

- Statutory requirements

- High replacement costs

- Critical roles in your overall operations

You also need assets where the failure rates increase with use. Basically, the more you use them, and as they get older, they tend to fail more often.

Planned unscheduled maintenance

This type of planned maintenance involves delaying the upkeep of an asset until a breakdown occurs. It might not sound like it, but planned unscheduled maintenance, the other name is run-to-failure maintenance, is a legitimate planned maintenance strategy. Although you do not expect a breakdown to happen, you plan the maintenance work beforehand so you can repair the equipment quickly.

Planned unscheduled maintenance is suitable in instances where the cost of reactive maintenance is less than the cost of preventive maintenance and the assets have little or no impact on production.

Planned unscheduled maintenance is a good fit for:

- Single-use assets with inexpensive parts

- Assets without statutory requirements

- Non-critical, low-criticality assets

- Assets with a low financial value

- Assets with shorter life cycles

You can also add assets that are unlikely to fail or have random failure patterns.

What is the difference between planned and preventive maintenance?

You can use the terms planned and preventive maintenance somewhat interchangeably, but they are not the same.

Preventive maintenance is the most common type of planned maintenance. Planned maintenance refers to any strategy where you plan and perform maintenance tasks before a fault occurs. Preventive maintenance is more specific. It refers to maintenance inspections and tasks you schedule and perform while an asset is still working to prevent it from failing unexpectedly.

What is the difference between planned and unplanned maintenance?

With either type of planned maintenance, you put the resources and parts in place to maintain an asset before a failure occurs. In the case of preventive maintenance, you schedule inspections and maintenance to take place at regular intervals to reduce the risk of a failure. But, with planned unscheduled maintenance, you plan the maintenance but do not schedule it or assign it to a technician until a failure occurs.

Unplanned maintenance, on the other hand, refers to any maintenance tasks that you do not plan. Unplanned maintenance commonly occurs after an asset or piece of equipment breaks down. As the maintenance work has not been planned, you may not have the parts or resources to do the repair, which increases the downtime and the costs.

Unplanned maintenance can occur when there is no formal maintenance strategy in place. However, it can also be a viable part of a balanced maintenance strategy for businesses with assets that are:

- Non-critical to operations

- Quick and cheap to repair

- Unrepairable at all

- Easily bypassed

There are three main types of unplanned maintenance that you can implement.

Reactive maintenance

This is unplanned maintenance to fix an asset or piece of equipment after an unexpected breakdown. In most cases, maintenance teams want to minimize the amount of reactive maintenance in their facilities, although it can be a suitable maintenance strategy for some non-critical assets.

Corrective maintenance

Corrective maintenance takes place when equipment stops working efficiently. It can include everything from minor fixes to large-scale repairs that resolve issues a business has not anticipated. Even equipment that undergoes regular preventive maintenance can receive corrective maintenance if you discover a fault before you have performed the scheduled preventive maintenance.

Opportunistic maintenance

Teams that implement this type of maintenance strategy capitalize on unexpected production stoppages to carry out preventive maintenance. This maintenance is not scheduled and relies on resources at the location making the most of a planned or unplanned shutdown of a system to replace or repair equipment and components.

As the maintenance planner or facilities manager, it is your job to consider the impact of failing equipment and to decide whether these three types of unplanned maintenance should be a part of your maintenance strategy.

How do you use planned maintenance?

There is a simple process that you can follow to structure and implement a planned maintenance program.

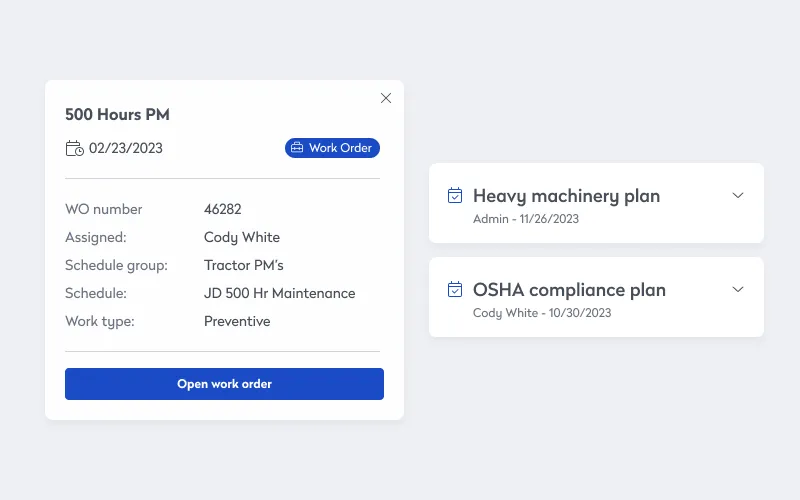

Step 1: Identify a problem and create a work order

The first step in any planned maintenance program is to identify a problem you want to solve. This information will usually come from the operator or supervisor who detects the issue. It should include the assets in question, details about the problem, and any other issues that relate to it. As the facilities manager or maintenance planner, you can create a work order or a repeating schedule to address it.

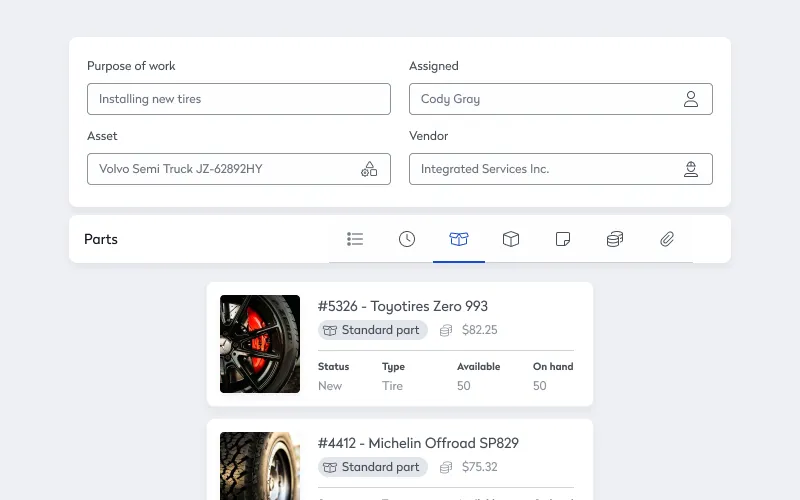

Step 2: Assess the worksite and the asset

Once you’ve created the work order, the next step is to inspect the asset and the site where you want to perform the work. You should document the scope of the work, the parts or materials required, and the tools the technician needs. You should also check that the worksite is accessible and there aren’t any complications that could hinder your team.

Step 3: Detail the process to complete the work and order the necessary parts

During the planning phases, it’s important to detail all the procedures required to complete the work. That includes the maintenance task itself, the safety precautions, and any access requirements.

Step 4: Assign the work order a priority level

Once you have outlined the work, you can then assign it a priority level. Some maintenance tasks are always more time-sensitive than others. A simple tip is to categorize maintenance tasks into one of four categories:

- Emergency tasks are urgent health and safety problems or issues that disrupt the business’s operations.

- High-priority tasks directly affect operations in the short-term.

- Medium-priority tasks typically include preventive maintenance that maintain peak production in the medium- to long-term.

- Low-priority tasks are not vital to the day-to-day operations of the business and include non-critical repairs, furniture replacement, and cosmetic issues.

You can then order the materials to complete the tasks with the highest priority level.

Step 5: Schedule and complete the planned maintenance

Now the planning phase is over, the scheduling can begin. This is typically the role of the maintenance planner or a specialist scheduler. The scheduling process is all about the “when” and “who” of the planned work. Scheduling will determine when you perform a maintenance task and who will do the work based on the priority level that you have given it.

How to make a planned maintenance checklist

Creating and implementing a planned maintenance strategy is only half the battle. You should also keep an eye on how it is performing after its launch. You can do that by creating a planned maintenance checklist.

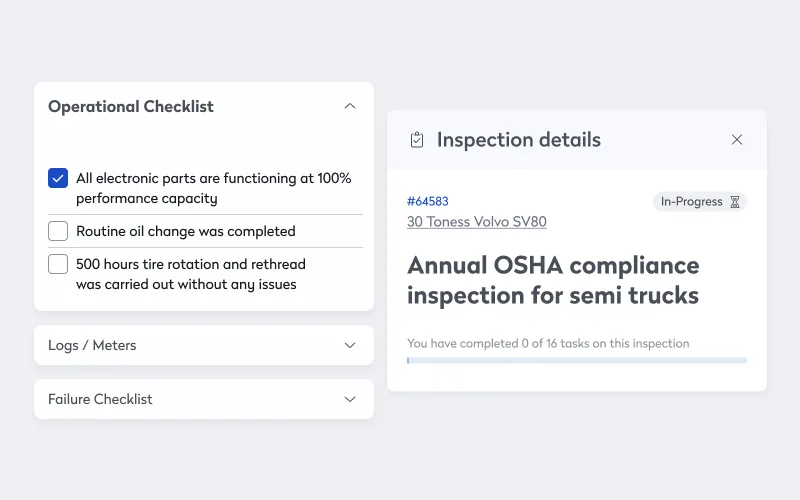

A planned maintenance checklist is an effective way to help track your maintenance key performance indicators (KPIs). It gives you a good idea of where the plan is working, how you can improve it, and the impact that it is having on your operational efficiency. Checklists are also a simple and effective way to standardize routine inspections and tasks.

Your planned maintenance checklist should include:

- Preparation details: A list of tools and spare parts your technicians need to perform the work and an estimated time for completion.

- Safety details: The safety instructions your technicians should adhere to, the personal protective equipment (PPE) they must wear, and details of lockout, tagout (LOTO) procedures.

- Visual aids: If necessary, you should also include pictures, diagrams, and videos on your planned maintenance checklist to help your technicians perform the work properly.

As well as this supplementary information, your planned maintenance checklist should also outline the actual steps involved in completing the work. The key to doing that well is to make sure all your information is:

Clear and concise

Including too much information in your checklist can be just as problematic as providing too little. The key is to imagine that you are outlining the steps involved for a new maintenance technician to follow. If a step needs a detailed explanation, then use a diagram or video if possible and always be precise. What might be obvious to you, such as an asset having two rather than one evaporator coils, may not be so obvious to a technician who has not worked on that asset before.

Explains the steps in order

Your checklist should provide a step-by-step description of the tasks the technician must perform in the order they should complete them. Every step that you include in your checklist must also have a purpose. If it doesn’t, then remove it. Once you have completed the checklist, run it by an experienced maintenance technician to check that you have not missed anything out.

Updates the information regularly

A planning maintenance checklist is not something that can stay in place unchanged. You should update it regularly in response to suggested adjustments from field technicians, changes in the location of assets, and when assets have been replaced.

What are the short-term benefits of planned maintenance?

Many of the long-term benefits are the result of running a preventive maintenance program over time, but you can see short-term benefits from just starting to set up your program.

Getting a complete list of all your assets and their current condition

When it comes to implementation, one of the first steps is creating an accurate, up-to-date asset list.

But why would this be the first step? It’s because a lot of maintenance departments don’t have one. Even though it’s their job to keep the organization’s assets up and running, the department doesn’t have a definitive asset list. It’s the same as someone asking you to babysit their kids but then not telling you how many kids they have. No matter how hard you try, there’s no way for you to be sure all the kids are safe.

And you’re creating more than just a simple list of what you have onsite. Part of the process is collecting and organizing the assets’ associated documents, including schematics, OEM manuals, and warranties. Jumping back to our babysitting analogy one last time, your list tells you not only how many kids you’re looking after but also their names, ages, favorite foods, and allergies.

And with your list, you now know what you have and have a good idea of each asset and piece of equipment’s condition. That’s because you don’t create an asset list sitting behind a desk. To make sure you include all your assets, you need to go around the facility and see what’s out there. And while you’re doing that, you have a chance to give each asset a thorough visual inspection.

So, one of the first short-term benefits is increased visibility for the maintenance department. Even before you start the program, you better understand how to best organize your department’s roles and responsibilities. Also, by looking closely at each asset, you get a sense of your starting point and the work you need to do.

Standardizing maintenance inspections and tasks for each asset

Once you know what you have, it’s time to sit down and figure out how best to look after it.

If you don’t have a PM schedule set up, there’s a good chance you don’t have standard practices set up either, which means that every time a tech works on an asset, they’re doing it differently, even if just a bit, then every other tech is doing it.

If every tech does the work differently, then logically, only some of them are doing it correctly. And even if techs do the work differently but are still somehow all close enough to best practices, you just end up with a different problem: when things go wrong, it’s hard to work backward to find out why. When you want to know why your forklift stops working after someone replaced a fan belt, you first must figure out which tech did the work and how they did it.

When everything is standardized, you know that every tech is doing the work the same way, correctly.

Better scheduling means fewer headaches, less stress

Once you have all your assets and their associated inspections and tasks worked out, it’s time to start building your preventive maintenance schedule.

The instant benefit here is that being able to schedule work makes work less stressful.

There’s hard science that backs up that common sense. According to a widely reported study, uncertainty is worse than knowing something bad is going to happen. Using a video game rigged to deliver electric shocks when players made mistakes, researchers proved that not knowing if you were getting zapped was more stressful than being sure you were.

The whole focus of preventive maintenance is scheduling ahead, catching small issues, and fixing them before they have a chance to grow into giant problems. Not only are you dealing with smaller tasks, but you can also see them coming, making them a lot less stressful overall.

What are the long-term benefits of planned maintenance?

Getting the program set up delivers plenty of benefits, and once it’s up and running, you can start to see some of the long-term benefits.

Optimizing Tribal Knowledge Transfer within the Maintenance Department

This one is closely related to the short-term benefit of standardizing maintenance inspections and tasks for each asset.

One of the big problems maintenance departments face is key person risk. The basic idea is that it’s risky to have important information, procedures, and processes locked up in one person’s head. If you lose them through transfer, promotion, or retirement, all that critical know-how walks right out the door with them.

The way to avoid this risk is through knowledge transfer. In the past, trades did this through both formal and informal apprenticeships, where senior techs paired up with junior ones to pass along their experience.

Modern preventive maintenance management software provides an alternative solution. Senior techs can help the department create PMs packed with their hard-won know-how, including:

- Step-by-step instructions

- Customizable checklists

- Digital images and schematics

Once the information is in the software, everyone on the maintenance team can instantly access it using any Internet-connected device.

Better inventory control

As soon as you know when techs are going to complete a PM, you also know exactly when you need the associated MRO inventory.

Instead of wasting money on rush deliveries because an asset is down and you need the parts right away, you can switch to a new inventory control model, where everything is set up so that parts arrive just before the team needs them, saving you money on both shipping and carrying costs.

More uptime, less unscheduled downtime

This one and the next one are generally the two biggest long-term attractions for preventive maintenance programs.

When you make the jump from reactive, on-demand maintenance to preventive maintenance, you can finally catch small issues before they develop into budget-busting disasters. Everything runs more smoothly for longer, maintenance costs less than repairs, and you get more control over when assets and equipment are down.

Now, instead of trying to find the broken part inside a critical asset while teams of operators stand idle, you can schedule PMs for when the line is already supposed to be down.

Longer asset life cycles, more value for your money

It’s the same advice you’d get from your doctor: an ounce of prevention is worth a pound of cure. It’s so much easier to avoid problems than it is to fix them. And even when we can fix them, things are never exactly as good as they were before.

After a car has been in a bad accident, it’s possible to fix it, but it’s never the same. That’s why people put “never been in an accident” in ads for used cars. It matters.

Preventive maintenance programs help you run assets for longer, and the longer the life cycle, the more value they return on that initial investment.

How can planned maintenance software help?

Relying entirely on an unplanned and reactive maintenance strategy is a bad idea, whatever industry you’re in. If you rely on heavy machinery or vehicles to keep your business moving, then implementing a planned maintenance program is a great opportunity to cut downtime, improve safety, and reduce your maintenance costs.

An easy-to-use maintenance management solution puts you in control of your planned maintenance. It enables you to build efficient and reliable workflows to keep your assets up and running. You can generate, assign, and track work orders, control your inventory, and get reliable automated reports that can improve visibility and create accountability.

Modern solutions include customizable maintenance checklists, so your maintenance technicians know exactly what to look out for, while planned maintenance scheduling helps to make sure you have the right people with the right skill sets in place and ready to work. That allows you to resolve maintenance issues more quickly and without having to rely on expensive overtime.