The oil and gas industry has always been volatile, shaped by shifting political landscapes, fluctuating markets, and global energy demands that can turn on a dime. From geopolitical tensions to environmental regulations and supply chain disruptions, energy companies must navigate a constantly evolving landscape. But while external forces remain unpredictable, one thing is entirely within an organization’s control: how well it maintains its assets.

For an industry built on high-risk, high-reward operations, the margin for error is razor-thin. A single equipment failure can result in production downtime that costs millions, regulatory fines that threaten financial stability, and worst of all, accidents that endanger workers. Yet, despite the obvious risks, many companies still rely on reactive maintenance — waiting for problems to arise before addressing them. This approach is not only outdated but also unsustainable in an era where efficiency, compliance, and safety are non-negotiable.

The companies that thrive in this industry don’t wait for disaster to strike. Instead, they invest in streamlined, proactive maintenance programs, using technology to detect issues before they escalate. A modern Computerized Maintenance Management System (CMMS) is no longer a luxury; it’s a necessity for keeping assets running, protecting profits, and most importantly, safeguarding people.

The cost of getting maintenance wrong

In a sector where equipment failures can have catastrophic consequences, delayed or inadequate maintenance is both costly and dangerous. Consider the impact of a single pipeline rupture. Not only does it halt operations, but it can also trigger an environmental disaster, attracting regulatory scrutiny, lawsuits, and irreparable damage to a company’s reputation.

The financial implications are staggering. Studies show that unplanned downtime in the oil and gas industry can cost companies upwards of $220,000 per hour and 32 hours of productivity each month. That rounds up annually to $84 million at each facility. These figures don’t even account for the long-term impact of lost production, emergency repairs, and reputational harm. In an industry where market fluctuations already threaten profitability, these avoidable costs can push even established firms into financial distress.

Then there’s the human cost. When heavy machinery, pressurized pipelines, and hazardous chemicals are involved, even minor lapses in maintenance can lead to catastrophic accidents. Equipment that isn’t properly serviced increases the likelihood of fires, explosions, and toxic leaks, putting employees and surrounding communities at risk.

For years, many companies accepted these risks as part of doing business, assuming that reactive maintenance was simply the name of the game. But with today’s advancements in digital asset management, that mindset is no longer justifiable. Organizations that fail to embrace preventive maintenance and data-driven decision-making are no longer just operating inefficiently — they’re operating irresponsibly.

Shifting from reactive to preventive maintenance

Despite the high stakes, many oil and gas companies still approach maintenance reactively, fixing problems after they occur rather than preventing them in the first place. This outdated approach creates a vicious cycle: the more reactive maintenance is required, the more emergency shutdowns and costly repairs occur, draining budgets and creating an unsafe working environment.

A preventive maintenance program, backed by a CMMS, disrupts this cycle. Instead of waiting for machinery to break down, teams can monitor asset health, schedule routine servicing, and predict failures before they happen. This shift from reactive to proactive maintenance transforms operations in three critical ways:

- It reduces unplanned downtime by ensuring that machinery is serviced regularly, and potential failures are caught early. This allows companies to operate with confidence, knowing that unexpected shutdowns won’t derail production.

- It improves asset longevity by preventing excessive wear and tear, extending the life of critical equipment and reducing the need for premature replacements.

- Most importantly, it enhances safety, ensuring that employees aren’t exposed to unnecessary hazards due to failing machinery or ignored maintenance issues.

Preventive maintenance isn’t just about avoiding breakdowns; it’s about creating a smoother, safer, and more predictable way to operate.

Leveraging CMMS to make preventive maintenance work

A successful preventive maintenance program requires more than just good intentions — it needs structure, automation, and real-time visibility. This is where a CMMS becomes an indispensable tool for oil and gas companies looking to stay ahead of potential failures.

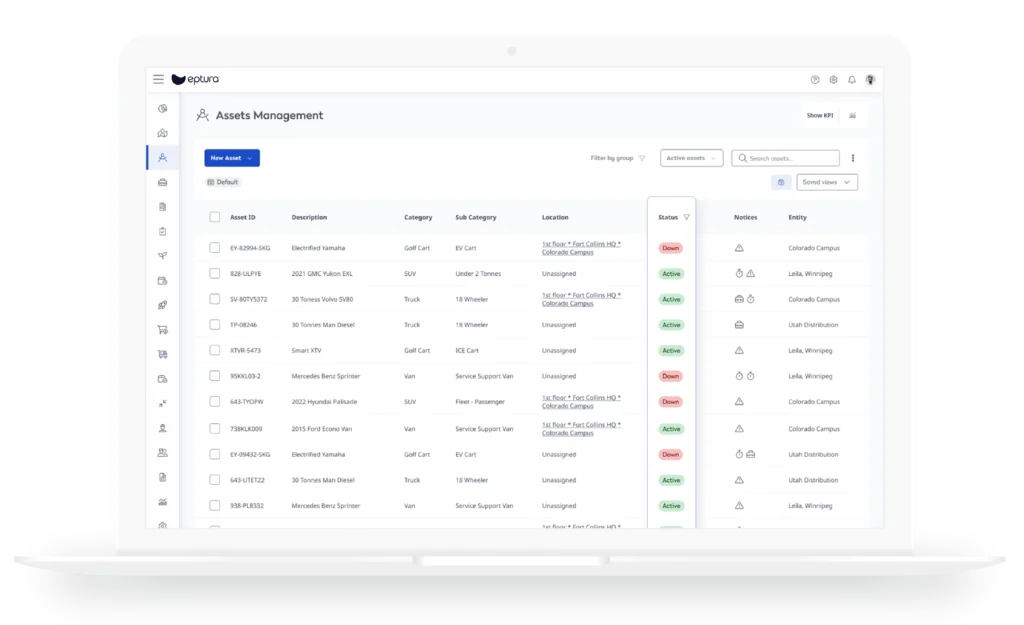

A CMMS centralizes asset data, making it easier for maintenance teams to track equipment performance, schedule routine servicing, and receive alerts when conditions indicate an impending failure. Rather than relying on manual logs or scattered spreadsheets, companies gain a single source of truth for all maintenance activities.

One of the most powerful features of a CMMS is its predictive analytics capabilities. By integrating with IoT sensors and real-time monitoring systems, the software can detect subtle shifts in temperature, pressure, or vibration — indicators that equipment is about to fail. Instead of responding to an emergency, maintenance teams can intervene early, addressing minor issues before they escalate into costly shutdowns.

A CMMS also plays a crucial role in compliance and regulatory reporting. The oil and gas industry is subject to stringent safety and environmental regulations, and failure to comply can result in heavy fines and legal action. With automated maintenance logs, real-time inspections, and audit-ready documentation, companies can prove compliance effortlessly, avoiding the last-minute scramble for records when regulators come knocking.

By incorporating a CMMS into daily operations, oil and gas companies aren’t just improving maintenance efficiency — they’re future-proofing their business against unexpected failures, regulatory penalties, and financial losses.

The broader business impact of a strong maintenance strategy

A streamlined maintenance program isn’t just a behind-the-scenes operational upgrade; it has far-reaching financial and strategic implications. By reducing downtime, companies can maximize output and ensure consistent revenue streams, even in volatile markets. By extending asset lifespan, they can avoid costly capital expenditures on replacements. And by improving safety and compliance, they can protect their workforce while minimizing liability risks.

More importantly, companies that invest in proactive maintenance gain a competitive edge. When an operation runs efficiently, it isn’t just more profitable — it’s more resilient to external pressures like shifting regulations, energy price fluctuations, and geopolitical uncertainty.

In an industry where margins are tight and risks are high, maintenance can no longer be viewed as an afterthought — it must be a cornerstone of business strategy.

The companies that thrive will be those that recognize the connection between operational efficiency and long-term sustainability — and that starts with a commitment to data-driven, technology-powered maintenance.

The future of oil and gas maintenance is proactive

The oil and gas industry has always been defined by risk, but in a world where technology enables predictive insights and real-time asset monitoring, there’s no longer an excuse for reactive maintenance. Companies that cling to outdated methods will find themselves struggling against rising costs, regulatory scrutiny, and preventable equipment failures.

By embracing CMMS-backed preventive maintenance, organizations can transform maintenance from a necessary expense into a strategic advantage. They can eliminate downtime, extend asset life, and most importantly, protect the people who keep operations running.

In an industry where every decision affects the bottom line, choosing a proactive maintenance approach is smart, and essential for survival. Those who get ahead of maintenance challenges today will be the ones still standing tomorrow.

Find out how Eptura Asset can help you stay one step ahead.