In the realm of maintenance management, the evolution from manual work order processes to automated systems has marked a significant leap toward operational excellence. This transformation is not merely about adopting new technology; it’s about reshaping workflows to achieve streamlined operations, enhanced efficiency, and consolidated systems.

The traditional landscape of work order management

Historically, organizations relied heavily on manual methods for managing work orders. This approach often involved paper-based systems or basic digital tools that required extensive human intervention. Coordinating tasks, tracking progress, and ensuring timely completion were labor-intensive processes prone to errors and delays. Such inefficiencies not only hampered productivity but also escalated operational costs.

Emergence of automation in work order processes

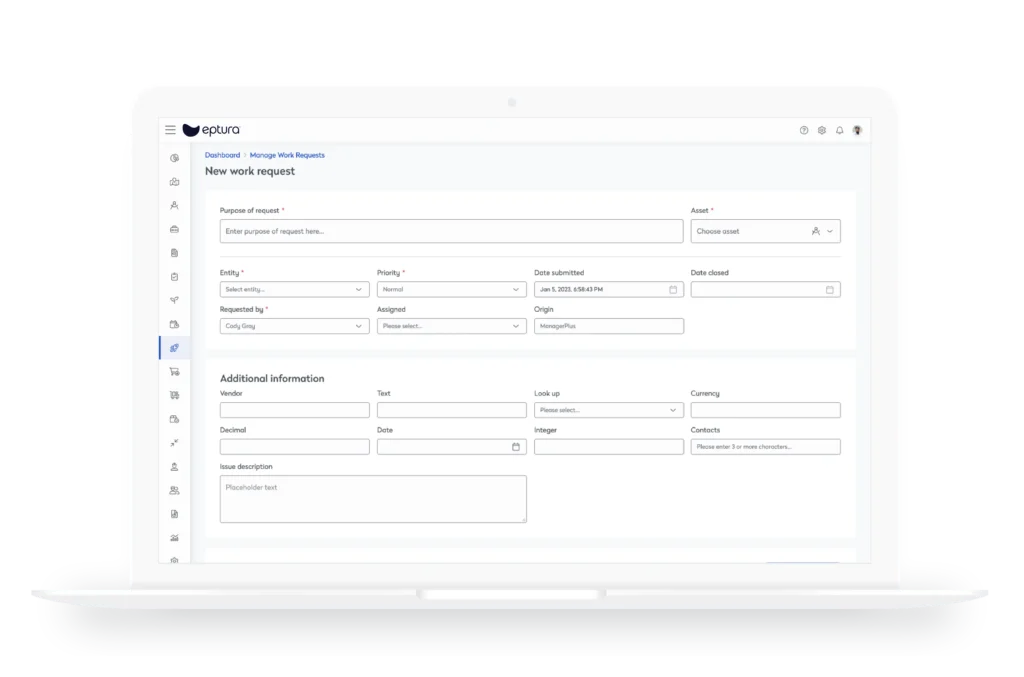

The advent of automation introduced a paradigm shift in handling work orders. By digitizing and automating these processes, organizations could now create, assign, and monitor tasks with unprecedented ease and accuracy. Automation facilitated the automatic generation of work orders based on predefined triggers — such as scheduled maintenance intervals or equipment performance metrics — thereby reducing the reliance on manual inputs and minimizing the risk of oversight.

Benefits of automated work order systems

Implementing automated work order systems has a multitude of advantages:

- Enhanced efficiency and productivity: Automation streamlines the entire workflow, enabling tasks to be completed faster and with greater precision. This efficiency allows maintenance teams to focus on critical issues rather than getting bogged down by administrative tasks.

- Improved accuracy and reduced errors: Automated systems minimize human errors associated with manual data entry and task assignments, ensuring that work orders are accurate and reliable.

- Real-time tracking and visibility: With automation, managers gain real-time insights into the status of work orders, facilitating better decision-making and resource allocation.

- Cost savings: By reducing manual labor and optimizing resource utilization, organizations can achieve significant cost reductions in their maintenance operations.

System consolidation through automation

Beyond individual task management, automation plays a pivotal role in consolidating various maintenance management functions into a unified system. Integrated platforms, such as Computerized Maintenance Management Systems (CMMS), offer comprehensive solutions that encompass work order management, preventive maintenance scheduling, inventory control, and asset tracking. By centralizing these functions, organizations can eliminate silos, enhance data consistency, and improve overall operational coordination.

Implementing automation: Considerations and best practices

Transitioning to an automated work order system requires careful planning and execution. Organizations should assess their current processes, identify areas that would benefit most from automation, and select a system that aligns with their operational needs. Training staff to adeptly navigate the new system is crucial to ensure a smooth transition and to maximize the benefits of automation. Additionally, integrating the automated system with existing enterprise solutions can further enhance efficiency and data coherence.

The road ahead: Embracing technological advancements

As technology continues to evolve, the potential for further enhancing work order management through automation is vast. Emerging technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) are poised to offer predictive maintenance capabilities, where systems can anticipate equipment failures before they occur and automatically generate work orders. Embracing these advancements will enable organizations to move from reactive to proactive maintenance strategies, further solidifying operational efficiency and system integration.

Work order success story: City of West Kelowna Water Treatment Plants

The City of West Kelowna, located in British Columbia, Canada, is known for its commitment to providing high-quality water services to its residents. The city operates several water treatment plants, each critical to ensuring the safety and reliability of the water supply. However, like many municipal organizations, the City of West Kelowna faced significant challenges in managing its assets efficiently and maintaining optimal operational performance.

The challenge

One of the primary issues the city was grappling with was the lack of a comprehensive and integrated asset management system. The existing processes were largely manual and fragmented, leading to inefficiencies, errors, and a lack of visibility into the maintenance and operational status of their assets. This not only increased the risk of equipment failures but also made it difficult to plan and budget for maintenance activities effectively. The city needed a solution that could centralize asset management, streamline maintenance processes, and provide real-time insights to enhance operational efficiency.

The solution

To address these challenges, the City of West Kelowna implemented Eptura Asset, a robust asset management software designed to optimize the lifecycle of assets. The decision to implement Eptura Asset was driven by the need to solve specific problems, including:

- Detailed budget tracking: The city required a more accurate and detailed way to track and manage budgets for maintenance and repairs. Eptura Asset’s purchase order system provided the necessary tools to monitor expenses and ensure that budget allocations were used effectively.

- Streamlined scheduling: Preventive maintenance was a critical aspect of the city’s operations, but the manual scheduling process was time-consuming and prone to errors. Eptura Asset’s preventive maintenance module allowed the city to schedule and track maintenance activities more efficiently, reducing the risk of equipment failures and downtime.

- Easier asset management: The city’s water treatment plants are spread across various locations, some of which have poor reception. Managing assets in these areas was particularly challenging. Eptura Asset’s parts barcoding feature made it easier for maintenance technicians to locate and manage equipment, even in areas with limited connectivity.

The result

The results of implementing Eptura Asset have been remarkable. The city has seen a 50% improvement in operational efficiency and productivity. This significant enhancement is attributed to the detailed view of each asset’s lifecycle and maintenance needs, which allows for more informed decision-making. The purchase order system has provided better budget tracking, ensuring that resources are allocated more effectively. The preventive maintenance module has streamlined scheduling, reducing the risk of equipment failures and downtime. Additionally, the parts barcoding feature has made asset management more efficient, particularly in areas with poor reception.

The city is also exploring the integration of CAD drawings into Eptura Asset to further optimize their operations. This integration will allow maintenance technicians to easily locate equipment using detailed floor plans, further enhancing their ability to perform maintenance tasks efficiently. The combination of these features has not only improved the city’s operational efficiency but also enhanced the overall reliability and safety of their water treatment plants.

For a deeper dive into the specific strategies and technologies used, and to learn more about the ongoing benefits and plans, explore the full case study.

Bringing it all together: The power of automation in a unified system

The integration of automation in work order management is more than a technological upgrade; it is a strategic move toward consolidating systems and enhancing operational efficiency. By adopting automated solutions, organizations can streamline their maintenance processes, reduce errors, cut costs, and gain valuable insights into their operations. As the landscape of maintenance management continues to evolve, embracing automation will be key to staying competitive and achieving long-term success.

Get in touch with Eptura to learn more about how we can streamline your work order management and overall asset maintenance strategy.