Today’s asset and facility managers are faced with the challenge of maximizing equipment reliability while minimizing maintenance costs. Unplanned downtime can lead to significant financial losses, decreased productivity, and compromised safety. To address these challenges, many organizations are turning to Reliability-Centered Maintenance (RCM) strategies, supported by advanced Enterprise Asset Management (EAM) software.

Understanding Reliability-Centered Maintenance (RCM)

RCM is a systematic approach to maintenance that focuses on ensuring assets continue to perform their required functions within their current operating context. It involves identifying potential failure modes, understanding their causes and effects, and implementing maintenance strategies to prevent or mitigate these failures. The primary goal of RCM is to enhance asset reliability, safety, and efficiency while optimizing maintenance resources.

The evolution of RCM

The concept of RCM originated in the aviation industry during the 1960s. Traditional maintenance practices, such as overhauling aircraft engines after a set number of flight hours, were found to be ineffective in improving reliability. Studies revealed that a significant percentage of component failures were not age-related, leading to the development of RCM as a more effective maintenance strategy. This approach has since been adopted across various industries to improve asset performance and reduce maintenance costs.

Benefits of implementing RCM

- Increased equipment uptime: By focusing on critical failure modes and implementing targeted maintenance strategies, RCM reduces unexpected breakdowns, leading to higher equipment availability. For instance, organizations that have adopted RCM have reported productivity increases of up to 27% and equipment effectiveness improvements of 97%.

- Cost savings: RCM helps in identifying and eliminating unnecessary maintenance activities, thereby reducing labor and material costs. Additionally, preventing failures can avoid costly repairs and production losses. Maintenance costs have been observed to drop by more than 22% following RCM implementation.

- Enhanced safety and compliance: By proactively addressing potential failure modes, RCM contributes to safer operating conditions and ensures compliance with industry regulations and standards.

- Optimized maintenance resources: RCM enables maintenance teams to focus their efforts on the most critical assets, improving overall efficiency and resource allocation.

Implementing RCM: A structured approach

Implementing RCM involves a systematic process that includes the following steps:

- Identify critical assets: Determine which assets are essential to operations and would have the most significant impact if they were to fail.

- Perform failure modes and effects analysis (FMEA): Analyze potential failure modes for each critical asset, their causes, and the consequences of failure.

- Prioritize failure modes: Rank failure modes based on their severity, occurrence, and detectability to focus on the most critical issues.

- Develop maintenance strategies: For each prioritized failure mode, develop appropriate maintenance tasks, such as preventive maintenance, predictive maintenance, or condition-based monitoring.

- Implement maintenance plans: Execute the developed maintenance strategies, ensuring that all necessary resources and training are in place.

- Monitor and review: Continuously monitor asset performance and the effectiveness of maintenance strategies, adjusting as necessary to optimize results.

The role of EAM software in RCM

Implementing RCM can be complex, especially in large enterprises with numerous assets. Enterprise Asset Management (EAM) software, such as Eptura’s solutions, plays a crucial role in facilitating RCM by providing:

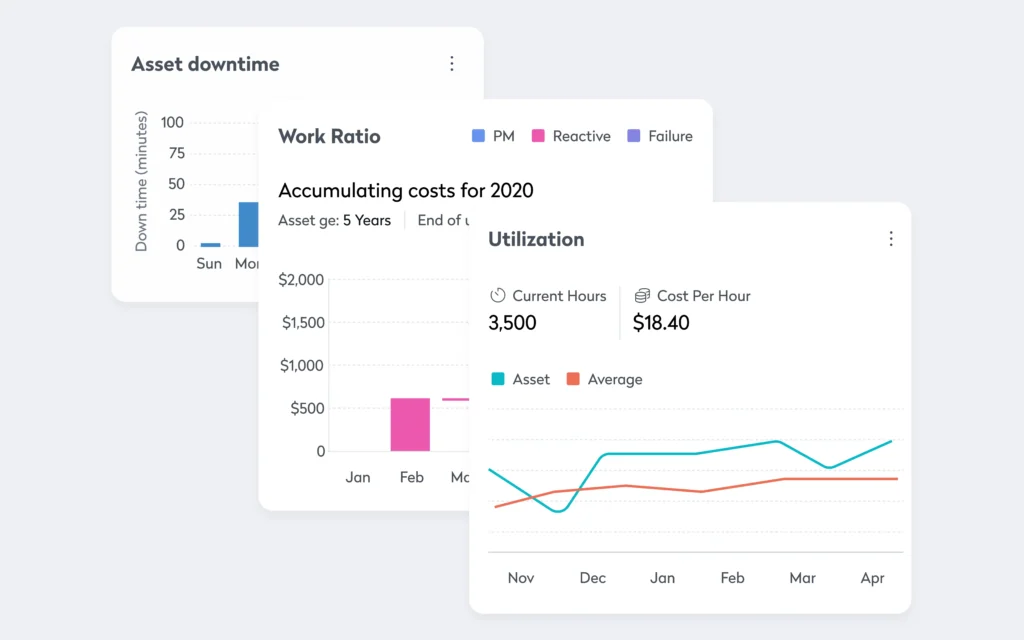

- Centralized data management: EAM software consolidates asset information, maintenance histories, and performance data, enabling informed decision-making.

- Automated maintenance scheduling: The software can automate the scheduling of maintenance tasks based on RCM analysis, ensuring timely interventions.

- Real-time monitoring and analytics: EAM solutions offer real-time monitoring of asset conditions and advanced analytics to predict potential failures before they occur.

- Regulatory compliance tracking: EAM systems help ensure that maintenance activities comply with industry regulations and standards, reducing the risk of non-compliance.

Eptura’s Enterprise Asset Management solutions

Eptura offers comprehensive EAM solutions designed to support RCM implementation in large enterprises. Key features of Eptura’s asset management software include:

- Preventive maintenance management: Streamline the planning and execution of preventive maintenance tasks to enhance asset reliability

- Asset lifecycle tracking: Monitor assets throughout their lifecycle to make informed decisions about repairs, replacements, and upgrades

- Inventory and vendor management: Efficiently manage spare parts inventory and vendor relationships to ensure the availability of necessary resources

- Mobile accessibility: Enable maintenance teams to access asset information and perform tasks remotely, improving responsiveness and productivity

EAM in action: City of West Kelowna Water Treatment Plants

The City of West Kelowna, located in British Columbia, Canada, operates two state-of-the-art water treatment plants that collectively serve a population of approximately 40,000. The Powers Creek Water Treatment Plant, commissioned in 2007 as Canada’s largest of its kind at the time, processes millions of liters of water daily alongside the newly opened Rose Valley Water Treatment Plant. Together, these facilities boast advanced technologies like UV disinfection, coagulation, and chlorination, ensuring safe drinking water for residents. However, managing such complex systems brought significant challenges.

By 2022, the West Kelowna team recognized inefficiencies in their asset and maintenance management processes. Despite bringing maintenance in-house in 2018 and implementing a Computerized Maintenance Management System (CMMS), the system’s work-order-based approach lacked the granularity to track asset lifecycles or provide a detailed view of maintenance histories. This limitation spurred the team to adopt Eptura Asset, a platform designed to streamline maintenance, improve data tracking, and enhance overall operational efficiency.

Eptura Asset introduced transformative technologies, including asset hierarchies, preventive maintenance scheduling, and parts barcoding for streamlined inventory management. These innovations addressed specific challenges like budget tracking, which had been previously unattainable at the necessary level of detail. Features like QR code scanning allowed technicians to instantly access asset specifications and maintenance histories, even in areas with poor reception. The system’s user-friendly purchase order tools enabled the team to analyze spending and forecast budgets effectively.

Since implementing Eptura Asset, the West Kelowna team has increased efficiency and productivity in their maintenance operations by an impressive 50%. Preventive maintenance tasks are now seamlessly organized, and real-time inspection forms flag issues automatically, ensuring immediate attention. The integration of barcoding and other intuitive features has simplified processes for both experienced technicians and new employees. With plans to incorporate CAD drawings for enhanced facility management, the team continues to explore new ways to leverage the platform’s capabilities.

Explore the full case study here.

It’s time to achieve operational excellence

Implementing Reliability-Centered Maintenance is essential for asset and facility managers aiming to enhance equipment reliability, reduce maintenance costs, and improve operational efficiency. Leveraging advanced EAM software like Eptura’s solutions can streamline the RCM process, providing the tools necessary for effective maintenance management.

Ready to enhance your asset reliability and optimize maintenance operations? Discover how Eptura’s Enterprise Asset Management solutions can support your Reliability-Centered Maintenance initiatives.