Occupational Safety and Health Administration (OSHA) violations quickly become costly. Fines for serious violations can reach $16,550, while willful or repeated violations can grow to $165,514 each. For facility managers, staying ahead of compliance requirements means having clear visibility into safety protocols, training records, and inspection schedules. Digital facility management tools make that possible by centralizing documentation and automating the workflows that support safer, more accountable operations.

Key takeaways

- OSHA fines are steep but preventable: Digital tools help facility managers stay ahead of inspections and avoid costly violations by automating safety checks and documentation

- Centralized records support compliance: With digital facility management software, training certifications, inspection logs, and equipment status are all stored in one place and easy to access during audits

- Automated workflows reduce human error: Standardized checklists and recurring task scheduling ensure that critical safety procedures aren’t missed, even during busy shifts or across multiple locations

OSHA sets and enforces workplace safety and health standards for both private and public sector employers in the United States. In addition to enforcement, OSHA provides training, outreach, education, and assistance to help organizations maintain safe working environments.

Understanding workplace safety OSHA compliance

OSHA compliance officers conduct unannounced facility inspections to assess workplace safety. During an inspection, the officer typically meets with the facility manager and walks through the site to identify potential hazards. After the walkthrough, the officer holds a closing conference to discuss findings.

If inspectors discover violations, OSHA issues a citation that outlines the specific issues, recommends corrective actions, and sets deadlines for compliance.

OSHA fines vary depending on the type and severity of the violation, and they can add up quicky. A single serious violation can cost more than $16,000, while willful or repeated violations can reach over $165,000 each. If hazards go uncorrected, daily fines may apply, compounding the total quickly. For companies with multiple infractions or systemic safety failures, penalties can escalate into the millions.

How a digital facility management solution streamlines fall protection compliance

Falls remain the leading cause of fatalities in the construction industry, and OSHA’s fall protection standard 29 CFR 1926.501 continues to top the list of most frequently cited violations year after year. The regulation requires employers to provide fall protection systems for workers at elevations of six feet or more in construction, and four feet in general industry.

Assign the right technician every time

Proper training is the foundation of fall protection. Staying compliant with OSHA’s fall protection standards, though, requires more than just checking a box. It demands ongoing coordination across people, equipment, and processes.

A digital facility management solution gives you the tools to manage all of it in one place, so you’re not relying on memory, spreadsheets, or disconnected systems.

You can use the software to maintain a centralized record of every technician’s certification. When a new work order comes in, for example for rooftop HVAC maintenance, you don’t have to guess who’s qualified. The system allows you to filter your team based on training records, so you assign the job to someone who’s certified to work at height and trained in fall protection procedures.

Because you can automatically log the assignment along with a timestamp and link to the technician’s profile, you have a clear audit trail if OSHA ever asks for documentation.

Attach safety protocols and link PPE to every task

Before the work begins, you use the platform to attach safety protocols directly to the work order. These include step-by-step instructions for using harnesses, anchors, and other fall protection gear. You also link the location of the required PPE, which you’ve already cataloged in the system.

If the technician needs a specific type of harness or gloves, they can check the inventory in real time and see exactly where to find it, whether it’s in a storage room or a satellite facility.

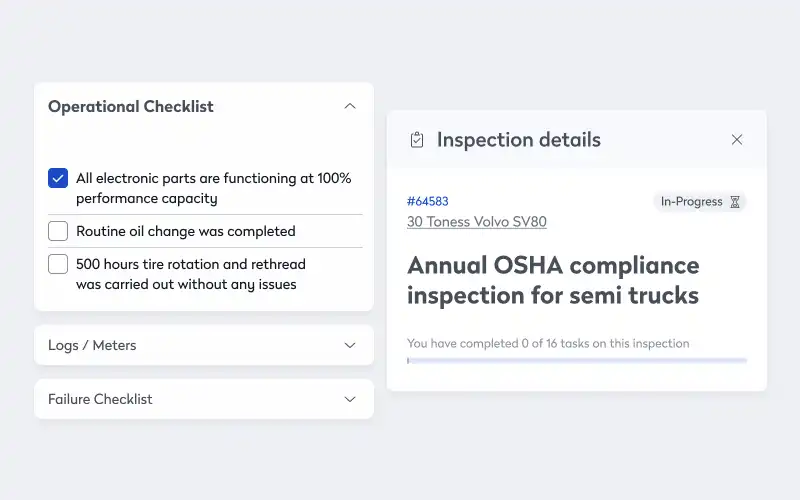

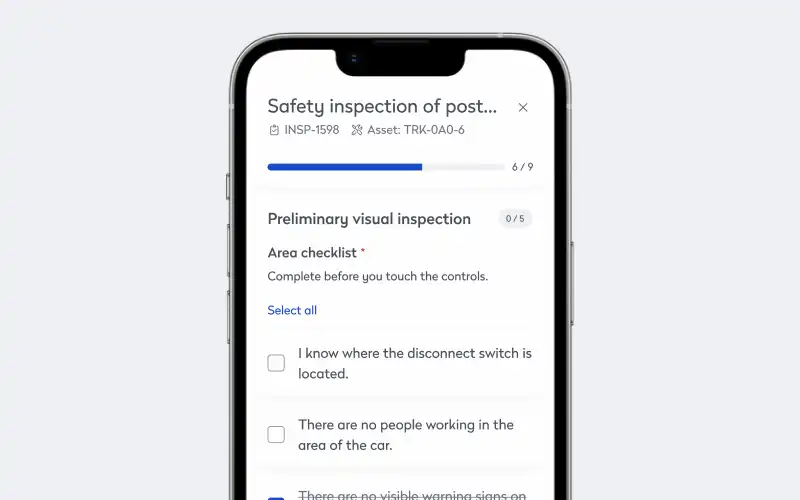

Automate digital safety audits and preventive maintenance checklists

You can also build preventive maintenance schedules into the system to ensure that fall protection equipment is inspected regularly. Anchors, harnesses, and lanyards are all tagged with inspection intervals, and you can set the software to automatically generate recurring tasks for your team. The team doesn’t miss any of the inspections, even during busy periods or shift changes.

The system also helps standardize how inspections are performed, so your team follows the same checklist every time, reducing the risk of human error and ensuring compliance with safety regulations. You can track completion rates, flag overdue tasks, and generate reports for internal reviews or external audits.

When the team flags a piece of gear for replacement after an inspection, the system alerts you before it’s assigned to a job, so you’re never caught off guard by expired or damaged equipment, and you can act quickly to keep your crew safe and your projects on schedule.

How a digital facility management solution supports hazard communication compliance

Hazard communication standard 29 CFR 1910.1200 ensures workers understand the chemicals they can encounter on the job. Employers are required to maintain accurate safety data sheets, properly label containers, and provide training on chemical risks and safe handling procedures.

Track employee training and certification for chemical safety

OSHA’s hazard communication standard requires that employees are trained to understand chemical hazards and know how to protect themselves. A digital facility management solution helps you meet this requirement by storing detailed training records for each employee.

You can set automated reminders for retraining intervals and generate reports that show which employees are cleared to handle specific substances. When assigning work orders, the system can filter your team based on training status, ensuring you choose only qualified personnel, improving safety.

Standardize labeling and documentation workflows

Proper labeling is a cornerstone of hazard communication, and a digital solution helps you enforce consistency across your organization. You can create templates for chemical labels that meet OSHA’s requirements, including signal words and hazard statements.

The system also supports documentation workflows for chemical handling procedures. For example, you can require technicians to complete a checklist before using a hazardous substance, confirm PPE usage, and log any incidents or spills. All of this data is stored in one place, giving you full visibility into how chemicals are managed and used across your facilities.

How a digital facility management supports machine guarding compliance

Machine guarding standard 29 CFR 1910.212 helps prevent injuries by mandating machinery have appropriate guards to protect operators and nearby workers from pinch points, rotating parts, and flying debris. Violations often involve missing or inadequate guards, especially on older equipment or during maintenance tasks.

Schedule and document guard inspections across all assets

Machine guarding compliance is about installing physical barriers and then maintaining them. A digital facility management solution allows you to schedule recurring inspections for every machine that requires guarding, from conveyor belts and presses to mixers and cutters. You can set inspection intervals based on manufacturer recommendations, usage frequency, or internal safety policies.

Each inspection task can include detailed instructions, photos of proper guard placement, and fields for technicians to log findings. If a guard is missing, damaged, or improperly installed, the system allows the technician to flag the issue immediately and trigger a corrective work order, creating a closed-loop process that ensures problems are addressed quickly and documented thoroughly.

You can also generate reports showing inspection history, compliance rates, and outstanding issues, which are valuable data for internal audits or OSHA inspections.

Include safety checks with work orders for real-time accountability

When assigning work involving machinery, you can embed safety protocols directly into the work order, including pre-use checklists that prompt technicians to verify guard placement, test emergency stops, and confirm that no bypasses are in place. The technician must complete these checks before marking the task as started, creating a timestamped record of compliance.

The workflow ensures that safety isn’t treated as an afterthought. If a technician identifies a hazard, they can log it immediately, and the system can escalate the issue to a supervisor or safety officer. Real-time accountability helps prevent accidents and supports a proactive safety culture.

Track equipment modifications and safety upgrades over time

Machine configurations change over time, and keeping track of those changes is essential for compliance. A digital facility management solution allows you to document every modification made to a machine, including guard installations, control upgrades, and safety retrofits. You can log who performed the work, when it was completed, and what standards were followed.

The historical record helps you demonstrate that your machines meet current safety requirements and that you’ve taken steps to improve protection over time. It also supports long-term planning by identifying which machines may need future upgrades or replacement due to evolving safety standards.

Digital safety tools help teams stay OSHA ready

OSHA compliance is complex, but digital facility management tools simplify the process. By automating inspections, tracking certifications, and standardizing safety protocols, facility teams can reduce risk, respond faster to issues, and maintain a clear record of accountability. It’s not just about avoiding fines. By embracing digital transformation, you can help build a safer, more resilient workplace.