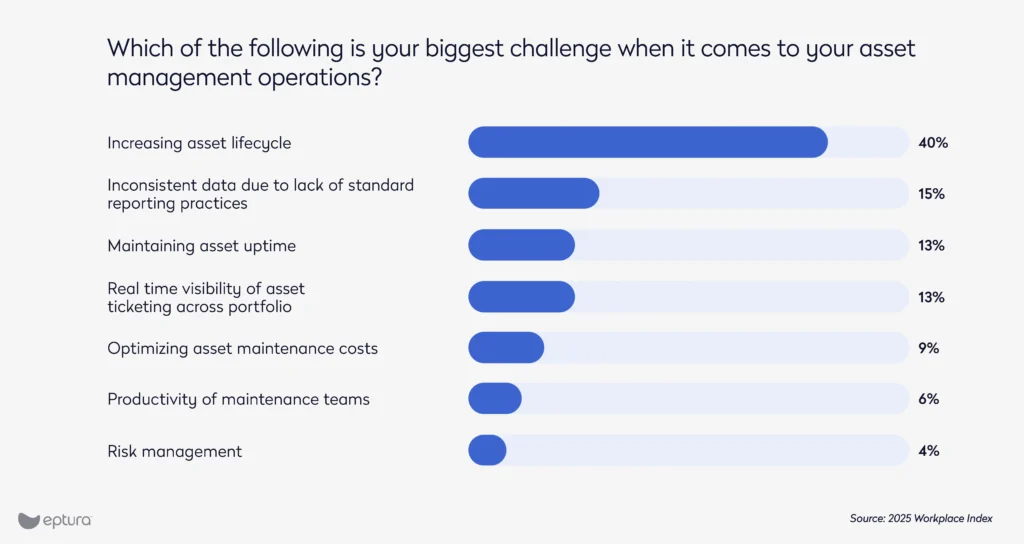

With the current and potential disruptions to the global supply chain, enterprises are putting risk management front and center in a noticeable uptick from the start of the year. In the January survey of operational leaders featured in our 2025 Workplace Index, most companies did not prioritize risk mitigation in the context of managing their physical assets. When asked, “Which of the following is your biggest challenge when it comes to your asset management operations?”, “Risk management” was the least popular answer at 4%. The most popular, “Increasing asset lifecycle,” was ten times higher.

At that time, respondents also indicated that reducing risk was not a top consideration in their long-range operational planning. When asked, “What is your key objective for the next 24 months when it comes to asset management?”, only 2% chose risk mitigation.

Now, however, we’re seeing companies refocusing on risk, especially in industries that rely on their assets to make products or deliver services like healthcare, airlines, manufacturing, fleet and transportation, and energy and utilities.

While there’s been less of a shift in industries that are more purely service-based, supply chain issues can affect anyone. For example, organizations planning renovations or upgrading their office furniture may need to re-examine project budgets. Some professional services businesses could even leverage current developments to add value for clients. Accounting firms, for example, could offer asset-reliant companies insights into their current supply chains and advice on where to optimize.

What companies can control: Cross-departmental complexity of the procedure to pay processes

The procure-to-pay (P2P) process encompasses the entire cycle from identifying the need for goods or services to making the final payment to suppliers. It is essential for maintaining operational efficiency, ensuring financial accuracy, and fostering strong relationships with suppliers.

One of its defining features is that it is a cross-departmental process, requiring coordination from teams across the enterprise, including:

- Procurement: Responsible for identifying needs, selecting suppliers, and managing the purchase requisition and purchase order processes

- Finance: Handles the financial aspects, including budgeting, invoice verification, and payment processing

- Accounts payable: Specifically manages the receipt and processing of supplier invoices, ensuring they are accurate and paid on time

- Operations: Ensures that the goods or services received meet the required standards and are integrated into the company’s operations

- Legal: Reviews and approves contracts and terms with suppliers to ensure compliance with legal and regulatory requirements

- Quality control: Inspects and verifies the quality of the delivered goods or services to ensure they meet the organization’s standards

In asset-heavy industries like manufacturing, construction, and logistics, the procurement team sources high-value assets such as specialized machinery and raw materials, while the finance department manages budgeting and ensures accurate invoice verification and timely payments. For example, in construction, the accounts payable team verifies invoices for large equipment rentals to avoid overcharges. The operations team ensures that received goods, like new fleet vehicles in logistics, meet the required standards. The legal department reviews contracts for compliance, and quality control teams inspect materials and equipment to ensure safety and performance.

Just as important as any one team’s work is their ability to share data and coordinate tasks across departmental lines. However, every business function has its own goals, which can create imbalances between teams.

Accounts payable and procurement: Cash balance versus supplier relationships

The accounts payable team often aims to pay invoices only when they are due to maximize the company’s cash flow. This strategy can help in maintaining a higher cash balance, which is beneficial for financial flexibility and interest earnings. However, procurement departments want to build and maintain strong relationships with the best possible suppliers. These suppliers may prefer shorter payment terms to ensure their own steady cash flow. Delayed payments strain supplier relationships, potentially leading to higher costs, reduced service quality, or even supply chain disruptions.

Procurement and quality control: Short-term savings versus long-term costs

The procurement department may prioritize cost savings and efficiency, which can sometimes lead to the selection of lower-cost suppliers. While this can reduce immediate expenses, it can also introduce risks related to the quality of goods or services. The quality control department, on the other hand, focuses on ensuring that the quality of delivered items meets the organization’s standards. Poor quality can lead to higher long-term costs, such as returns, rework, and customer dissatisfaction.

All of these challenges increase as companies scale. Because the root cause for all these issues is lack of organizational alignment, the larger the company, the more critical it becomes to agree on the right balance between team objectives up front.

When the departments work together, Procurement can prioritize cost savings while helping Quality Control ensure goods and services meet standards. By collaborating closely, the procurement team can jointly evaluate suppliers with quality control to ensure that lower-cost equipment parts, for example, do not compromise quality. Quality control provides ongoing feedback on the performance and reliability of delivered items, helping procurement to make better informed decisions. The partnership ensures that all purchased assets meet the required standards, reducing the risk of returns, rework, and customer dissatisfaction.

Where companies can mitigate risk: External factors affecting the supply chain

There are many links in any supply chain that a company can’t control.

Natural disasters, such as hurricanes, earthquakes, and floods, can disrupt the supply chain by damaging infrastructure, disrupting transportation, and causing production delays. For example, a factory in a disaster-prone area might be forced to shut down, leading to a shortage of critical components.

Human factors like trade policies, political instability, and international conflicts can also significantly affect the supply chain. Changes in trade regulations, such as tariffs and import/export restrictions, can increase costs and create delays. Political instability in supplier countries can lead to supply disruptions, while international conflicts can result in sanctions or embargoes that limit access to certain materials or markets.

Compounding the challenge is that the global supply chain is a dynamic and ever-changing environment. Market conditions, customer demands, and technological advancements are constantly evolving. Companies need to design their asset maintenance processes – from finding ways to increase the life cycle of mission-critical equipment to diligently managing parts inventory and suppliers – to be agile and responsive. For example, a sudden surge in demand for a product can strain the supply chain, while new technologies can render existing processes obsolete.

How an enterprise can improve: Counteracting complexity and mitigating risk by moving toward the right on the value chain

When supply chains slow and shrink, organizations start asking themselves tough questions about their existing operations. Siloed systems make it hard to even find accurate answers, while connected, intelligent workflows empower companies to create solutions.

For example, a company that finds itself facing a new tariff would want to know:

- What’s the source of the cost increase?

- Is it coming from a single country?

- How much of our manufacturing is based in that country?

- How much labor do we have in that country?

- Where does the output from that country go in terms of our customer base?

- Who are those customers?

- Which customers are least (or most) sensitive to price changes?

- What are our contractual obligations?

- Do our contracts with customers allow us to pass on the increased costs?

- Do we have any contractual agreements with vendors that allow us to push back on the cost increase?

- How will tariff-related supply chain disruptions impact our service level agreements, and how can we mitigate this?

In a siloed approach, each department might focus on its own immediate concerns without considering the broader implications of their answers. The result is fragmented decision-making and increased vulnerability to supply chain disruptions.

A more integrated approach involves cross-departmental collaboration and a holistic view of the supply chain that also includes an accurate understanding of on-hand inventory and forecast use rates. By working together, departments can identify and implement strategies to mitigate the impact of cost increases. For example, procurement could explore alternative suppliers, finance could adjust pricing strategies, and operations could optimize production processes to reduce costs.

To discuss ways to optimize your asset operations and manage risk, connect with our consultancy.