In industries where precision is critical, including manufacturing, pharmaceuticals, aerospace, and energy, equipment calibration programs help ensure measurement instruments provide accurate readings within defined tolerance levels. Equipment calibration programs support product quality, operational efficiency, and regulatory compliance. To keep these programs running smoothly, many facility and maintenance teams are turning to mobile maintenance apps that help technicians stay organized, accurate, and on schedule.

Key takeaways

- Calibration is essential for safety and compliance: Accurate measurements are crucial for quality control, safety, and regulatory compliance. Calibration errors can lead to serious consequences like equipment damage and safety risks

- Mobile maintenance apps improve calibration workflows: Tech apps help technicians stay organized, reduce errors, and complete calibration tasks on time, including remote or low-connectivity areas

Common calibration errors can have serious consequences, with mistakes like neglecting manufacturer guidelines or skipping environmental controls leading to equipment damage, regulatory violations, and safety risks.

An equipment calibration program provides the structure and accountability needed to manage these risks effectively. It ensures that measurement tools are regularly assessed and adjusted to meet defined tolerance levels, supporting both safety and efficiency across operations.

What is equipment calibration?

Calibration is a two-step process. First, an instrument’s accuracy is evaluated by comparing its readings to a known standard. Second, the instrument is adjusted to bring its measurements within acceptable limits.

The required level of accuracy depends on the application. For example, a laboratory scale used in pharmaceutical research must be far more precise than a pallet scale used in logistics.

Commonly calibrated instruments include:

- Pressure: sensors, barometers

- Temperature: thermometers, thermocouples

- Flow: flow meters

- Mechanical: volume, mass, force, torque, vibration

- Electrical: voltage, current, resistance, frequency

Each of these instruments plays a critical role in maintaining process control and product quality. Without regular calibration, even minor deviations can compound into significant operational issues.

Difference between accuracy and precision in calibration

Calibration ensures both accuracy and precision, which are distinct but complementary concepts.

Accuracy refers to how close a measurement is to the true value. For example, if water boils at 100°C at sea level, a thermometer reading 99.9°C is considered accurate

Precision refers to the consistency of repeated measurements. If multiple readings are closely grouped, the instrument is precise even if they are not accurate.

That means an instrument can be precise but inaccurate, or accurate but imprecise. Effective calibration aims to achieve both.

Common types of calibration

There are two primary calibration methods:

- Relative calibration: Compares an instrument’s readings to those of another, already calibrated device. It is commonly used when a reference instrument is available and trusted

- Absolute calibration: Compares readings to a fixed, internationally recognized standard. For example, the kilogram is now defined using fundamental physical constants such as the Planck constant and the speed of light

Both methods require careful attention to environmental conditions, instrument setup, and documentation to ensure reliable results.

Why is equipment calibration important?

Accurate measurements are essential for quality control, safety, and regulatory compliance. In food production, for instance, precise ingredient measurements ensure consistent taste and texture. In manufacturing, incorrect temperature readings can compromise material bonding, leading to product defects.

Calibration errors can also pose safety risks. Improperly calibrated pressure sensors may fail to detect dangerous spikes, potentially leading to equipment failure or hazardous leaks

In pharmaceutical environments, for example, inaccurate temperature readings can result in storing medicine at unsafe conditions, compromising efficacy and patient safety.

Calibration helps create reliable traceability. By documenting calibration activities and linking them to recognized standards, organizations can demonstrate compliance during audits and investigations.

How does industry affect calibration requirements and best practices?

Calibration requirements and best practices vary significantly across industries, shaped by the nature of operations, regulatory oversight, and risk tolerance. While the core principles of calibration—accuracy, precision, traceability—remain consistent, the implementation details differ based on sector-specific standards and compliance frameworks.

Calibration in food processing

In food manufacturing, calibration is essential for ensuring product safety, consistency, and regulatory compliance. Instruments such as thermometers, pH meters, and scales must be regularly calibrated to prevent contamination, spoilage, and mislabeling. According to the U.S. Code of Federal Regulations 21 CFR Part 113, thermometers used in thermal processing must be tagged with the date of their last calibration

Beyond tagging, food processors must maintain detailed records of calibration activities and ensure that instruments are calibrated against recognized standards. Hazard Analysis and Critical Control Points regulations require documented calibration of monitoring devices to verify that critical control points like temperature and pressure are within safe limits.

Calibration in aerospace

In aerospace, calibration is critical for ensuring the reliability of flight systems, navigation instruments, and safety mechanisms. Regulatory bodies such as the Federal Aviation Administration and European Union Aviation Safety Agency require strict adherence to calibration protocols.

Calibration in this sector often involves high-precision instruments with narrow tolerance ranges, redundant verification using multiple standards, environmental controls to simulate operational conditions, and compliance with ISO 17025 for calibration laboratories

Traceability is especially important in aerospace, where every measurement must be linked to a recognized standard through an unbroken chain of comparisons. This ensures that any deviation can be traced back and corrected before it affects flight safety or mission performance.

How does a mobile maintenance app support a calibration program?

Calibration programs are only as strong as the systems that support them. When technicians have access to the right tools, they can complete calibration tasks with greater accuracy, speed, and consistency. Mobile maintenance apps bring structure and visibility to these workflows, helping leads stay confident that every adjustment is properly tracked and every deadline is met.

Work order management keeps calibration on schedule

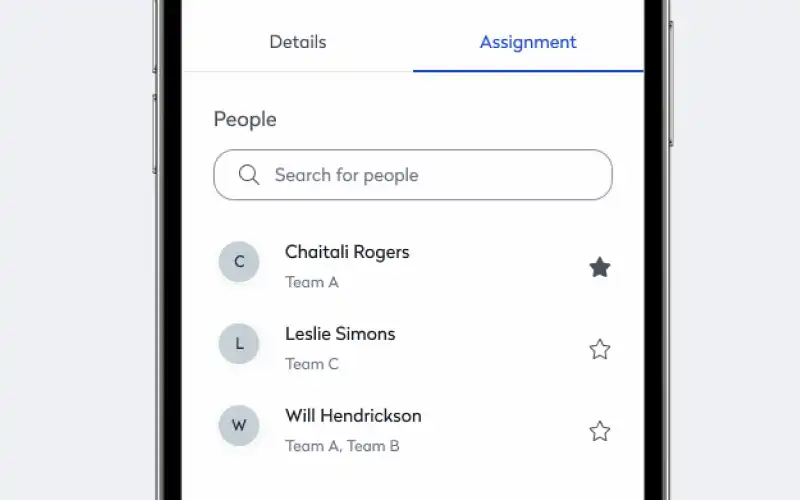

In a busy manufacturing plant, for example, calibration tasks often compete with reactive maintenance and inspections. A mobile app helps you prioritize and assign calibration work orders with clear instructions and deadlines, so technicians know exactly what needs to be done and when.

Leads can monitor progress in real time, reducing the risk of missed intervals and ensuring compliance with internal standards or external regulations. When calibration tasks are embedded in the same workflow as other maintenance activities, they’re less likely to fall through the cracks.

Asset history supports accurate adjustments

At a busy hospital where the team needs to calibrate biomedical equipment regularly to meet safety standards, a mobile app that provides instant access to asset history allows technicians to review previous calibration data. The data helps them avoid overcorrection and ensures consistency across calibration cycles. Leads can also use historical data to identify trends, such as equipment that frequently drifts out of spec, and make informed decisions about replacements or upgrades.

Barcode scanning reduces identification errors

In a large food processing facility, technicians may need to calibrate dozens of similar temperature sensors across different production lines. Barcode scanning within a mobile app ensures that each technician is working on the correct asset.

Scanning a label instantly pulls up the calibration schedule and past records, eliminating guesswork and manual data entry, helping improve accuracy and speeds up the workflow, especially when technicians are moving quickly between stations.

Offline access keeps remote calibrations moving

Facilities with remote infrastructure, like water treatment plants or wind farms, often require calibration work in areas with poor connectivity. With a mobile app with offline capabilities, technicians can access calibration instructions and log results without needing a signal. Once back online, the data syncs automatically, keeping records complete and up to date. Leads can trust that calibration work is being done correctly, even in the most challenging environments.

Voice assistance streamlines calibration in the field

In high-pressure environments like manufacturing floors or hospital maintenance wings, technicians often need to move quickly and stay focused. Technician Copilot’s voice-enabled mobile support makes that possible by allowing hands-free access to calibration instructions, asset data, and work order updates. Instead of stopping to type or scroll through screens, technicians can speak commands and log results on the go—keeping their hands on tools and their attention on the task.

This ease of use translates directly into improved productivity. Technicians can complete more tasks in less time, with fewer interruptions and less risk of transcription errors. Voice assistance also helps standardize data entry across teams, ensuring calibration records are complete and consistent. Leads benefit from faster updates and clearer visibility into task progress, making it easier to stay ahead of deadlines and maintain compliance. By embedding voice functionality into mobile workflows, Technician Copilot helps field teams work smarter, faster, and with greater confidence.

Calibration is more than compliance

A well-executed equipment calibration program is more than a compliance checkbox. It’s a strategic investment in safety, quality, and operational reliability. From food processing to aerospace, each industry brings its own standards and expectations, but the goal remains the same: trustworthy measurements that support consistent outcomes.

By understanding the nuances of calibration across sectors and implementing best practices tailored to your environment, you can reduce risk, improve performance, and build a foundation for long-term success.