Maintenance contracts are essential for ensuring the smooth and efficient operation of many assets. Although the numbers vary across industries, and for larger organizations they can be different depending on location and facility, third-party providers can account for a significant percentage of regular asset and equipment work, making maintenance contracts and service agreements an important part of planning and scheduling.

But before you can negotiate the right maintenance plan for your facility, you need to know the possible benefits of outsourcing, the types of maintenance contracts there are, and the terms and conditions you likely want to include.

What is a maintenance contract?

A maintenance contract is a legal agreement between your organization and a maintenance service provider that outlines:

- What work they’re going to do

- When they’re going to do it

- How quickly they can complete the work

- What standards they must meet

Whether it’s general upkeep or more specialized maintenance and repairs, the agreement must specify all the terms and conditions for everyone involved. It should include everything from the extent of the provider’s responsibilities to the service completion times, and compensation if the provider damages your equipment or property.

You should carefully negotiate the terms of the maintenance contract before you commit to working with a service provider. The more you spell things out in the agreement now, the easier it is to resolve any issues in the future.

How do you know you need a maintenance contract?

When it comes to the maintenance of your equipment and facilities, there are four basic options.

You can use:

- In-house maintenance teams

- Original equipment manufacturer (OEM) technicians

- Third-party maintenance service providers

- Any combination of the above three options

It’s most common for organizations to need at least some outside help either because of workload or the costs associated with hiring experts full-time for tasks that should only ever be periodic or infrequent.

For example, in many locations, only certified specialists can do inspections and testing on your fire suppression systems. For elevators and escalators, you also very likely need someone with a lot of specialized training. But because, hopefully, you might only work on the sprinklers and elevators a few times a year, it doesn’t make economic sense to have these techs on the team all the time.

So, if you have work you cannot do yourself because of a lack of resources or because it’s specialized work your team cannot do either legally or safely, you need maintenance contracts.

What are the benefits of maintenance contracts?

Not everyone has a large, fully staffed in-house maintenance department at every facility across multiple locations, and even if you do, you may have assets or equipment no one on the team is officially qualified to inspect, test, maintain, or repair. The obvious solution is to outsource a part of your maintenance responsibilities to licensed, certified experts.

By choosing an outside provider, you can bring in experts who understand your assets and equipment and can provide a level of service you can’t match, ensuring the maintenance department is having the work completed to the highest possible standards to meet reliability goals and regulatory requirements.

Maintenance agreements help reduce your organization’s legal liability. A service provider should have insurance to cover them in an accident. Liability, responsibility, and coverage limits are something to discuss when negotiating the terms of your service agreement.

Handing the responsibility for your maintenance over to a contractor can also help to reduce inventory costs. They have the tools and spare parts they need to keep your equipment in the best possible condition, so you can direct your limited budget elsewhere. So, for example, the team that inspects your sprinklers are the ones who invest in the required specialized hardware and software. For them, it makes sense because that’s the only type of work they do. But for you and your maintenance department, spending money on tools you only use a few times a year is likely a poor investment.

What are the different types of maintenance contracts?

Annual maintenance contracts (AMC) and comprehensive maintenance contracts (CMC) are the two general types. Both cover the service charges for ongoing maintenance and emergency repairs. The main difference between the two is the levels of service they provide.

Annual maintenance contracts vs. comprehensive maintenance contracts

An AMC is an effective way to cover the basic maintenance of your equipment, but it only covers the service itself. You pay extra for any expenses you might incur during maintenance. A CMC covers all the costs of performing the maintenance work as well as all parts and labor, the transportation for technicians, and any additional related costs.

With every aspect of the service covered, comprehensive maintenance contracts cost more initially, but you don’t have to worry about any of the additional invoices you’re likely to receive with an annual maintenance contract.

Once you’ve decided whether an AMC or CMC is the best fit for you, you can then think about finding the right type of maintenance contract for your overall maintenance strategy. For example, you may only want to bring in outside help when there’s a problem. On the other hand, you may be looking for a preventive maintenance provider who can help you avoid problems in the first place.

Corrective maintenance

As the name suggests, this is a service agreement for when something goes wrong. Equipment downtime is expensive, so the provider must act quickly to restore the asset to its normal operating condition. The unplanned nature of the work means this type of maintenance agreement usually costs more.

Preventive maintenance

Here, the maintenance provider regularly carries out planned maintenance to identify and repair minor issues and prevent them from becoming big problems. Your provider must complete pre-defined checks and tasks at scheduled intervals to help you avoid failures.

Risk-based maintenance

By analyzing past failures, you can predict how and when future failures are likely to occur. You can then instruct your maintenance provider to carry out maintenance tasks based on our predictions.

Effective, efficient asset management depends on reliable data you can leverage into actionable business intelligence. With a modern asset management solution, facility and maintenance management professionals can automatically capture good data, keep it safe and accessible, and run reports to leverage raw data into insights.

Condition-based maintenance

Here, your provider monitors the condition of your equipment and performs maintenance when it’s required. First, you need to install sensors on your critical assets, and then set them up to deliver a flow of real-time data to specialized software that looks for anomalies. For example, a simple temperature sensor on a motor can tell you when the asset is overheating. Or a vibration sensor on a fan can tell you when there’s too much wobble. It’s usually best to use this type of maintenance in conjunction with other types of agreement.

How long do maintenance agreements typically last?

The initial term for AMCs and CMCs is usually a year, although you could put a three or five-year deal in place with your provider if you’re satisfied with their work.

Long-term contracts can benefit both your organization and the maintenance provider. From your point of view, having a reliable contractor in place gives you one less thing to worry about for the length of the agreement. A long-term contract can also lead to a consistent level of service, often at a discounted price, helping to reduce your annual maintenance costs without sacrificing quality on parts, processes, or people.

From the provider’s point of view, long-term contracts give them a regular source of income and allow them to build strong relationships that can lead to case studies and valuable recommendations. They also have an incentive to provide an excellent level of service, which in the end also benefits you.

How do you set a price for service agreements?

Regardless of the benefits, important maintenance decisions almost always come down to cost. Many factors determine how much you’re likely to pay, such as the number of assets you have, the contract length, and the maximum number of breakdowns you want to cover.

Different pricing methods can usually be negotiated with your provider, including:

- Per device pricing: You agree on a price with the maintenance provider for servicing a single asset for the duration of the contract. The total cost is the price per asset multiplied by the number of assets you have.

- Time-based pricing: Your contract may specify a fixed hourly rate. You multiply the total labor hours by the hourly rate to find the total cost.

- Asset lifetime pricing: Your provider may charge more for older assets, which typically require more regular maintenance

- Replacement vs. repair: The price you pay can change depending on whether you want to repair or replace certain assets or components when they break

Which one works best for a company depends on many factors, including industry, types of assets and equipment, and the quality and variety of local providers.

What should you look for before signing a maintenance agreement?

A good general maintenance agreement needs flexibility, clear expectations, and a fair conflict resolution process. But that might be just the start.

Clear description of the services

It sounds obvious, but at the most basic level you need to make sure there’s a clear description of the services you’re going to receive in the contract, including schedules, with zero ambiguity. When an asset or piece of equipment fails, the last thing you need is to discover the contract doesn’t cover their repair or replacement.

Appropriate measure of service level

Maintenance contractors usually have their own objective measures, response times, and service availability, but do they reflect what’s important to your business? If they don’t, suggest some that do. What makes sense for the provider might make less sense for you, and because you’re the customer, providers should be accommodating your needs, not the other way around.

Flexible services and pricing

Things change in business. You could take on new sites, establish new service lines, or drop others. Your maintenance agreement should have enough flexibility built into the pricing and services to manage those changes. From a pure business point of view, service providers should generally want you to expand because that means more work for them. But, in some cases, a provider is already at, or close to, their limit for time and other resources right at the start of the contract. It might make sense to go with someone who is in a better position to scale with you.

Built-in ability to walk away from poor service

The last thing you want is to be tied to a service provider that consistently fails to achieve service levels without a way to exit the agreement. Most maintenance contracts contain a general termination clause if the provider is in material breach but think about whether you may want more specific rights for performance defaults. You should also look at any language in the agreement about conflict resolution. Could you escalate to court if you needed to, or are you locked into a form of mediation that favors the other party?

Clear exit schedules

Treat the exit as part of the overall project, and the assistance you get at the end of the agreement should be well documented. As well as the handover of physical equipment, think about the transfer of knowledge, such as equipment data. It’s also good practice to review and update the exit schedule annually to make sure it reflects any changes.

What should your facility maintenance contract include?

A facility or building maintenance contract should contain:

- Full names and details of both parties

- Types of maintenance

- Scope of the work

- Equipment details

- Service schedules

- Response times

- Service completion times

- Payment terms

- Warranties, guarantees, and compensation

- Contract termination details

For the full name and details of both parties, this is mostly a question of covering your legal bases. Make sure to include the names of your organization and the service provider, your registered addresses, the location, where the service is going to be delivered, and details of signatories. Then make sure you add the type of maintenance.

The contract should clarify the type of maintenance you need, whether it’s on-demand, preventive, or condition-based, for example. For the scope of the work, expect to see a clear outline of the services the provider is going to provide, making sure to describe the jobs explicitly to avoid any ambiguity. You also need equipment details. Here, include the technical specification, location, operating conditions, and other relevant information about the assets you want the provider to service.

The more they know about your assets, the easier it is for them to help you keep everything up and running.

That covers the “who” and the “what.” But you also need to include the “when.” For the service schedule, include when your provider will perform the work. For preventive maintenance, you can specify the intervals. For response times, clearly define the maximum response time from the contractor, especially for critical assets.

Next, look at service completion times. You need to know that the provider can complete the work within reasonable timeframes.

Next, you need to cover the “how much.” For payment terms, ask yourself: How much are we paying for the work and when are we making these payments? You should also establish how you’re going to make the payments.

It may seem like a smaller aspect, but keep in mind that every payment method comes with some combination of convenience and complexity.

When looking at warranties, guarantees, and compensation, make sure you have some form of protection in place if the contractor fails to meet the service standards you’ve agreed on or they damage your assets or equipment.

And finally, the details on contract termination. Every service agreement should include a clause that clarifies when and how you or the contractor can terminate the contract.

How a modern integrated facility and asset management platform can help you manage maintenance agreements and vendors

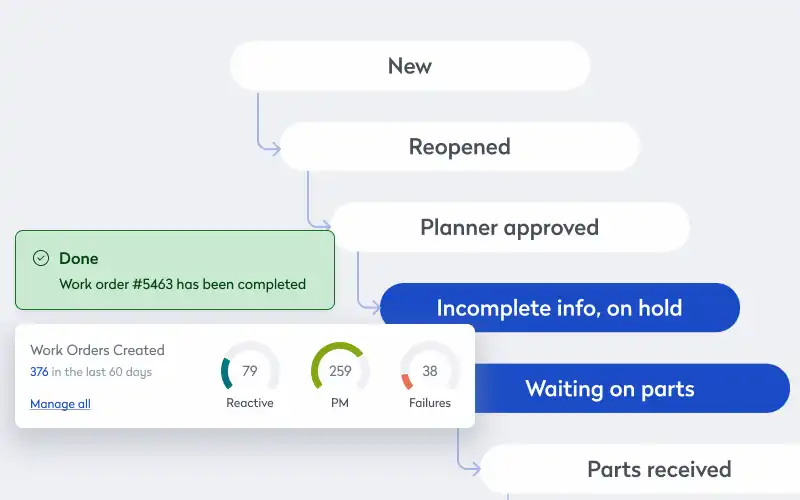

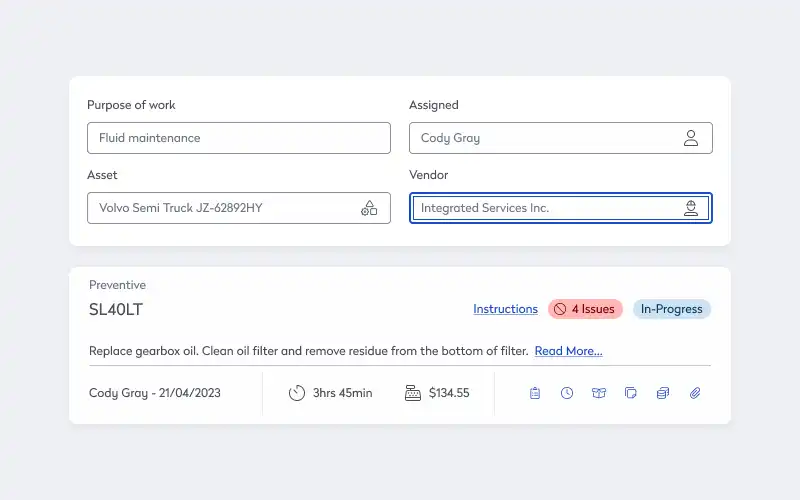

Keeping information on multiple vendors across multiple sites organized, searchable, and accessible is a challenge when you’re forced to rely on manual methods. Modern asset management solutions make it easy to handle every aspect of your facility maintenance data.

You can upload files, including facility maintenance contracts, so you have all your maintenance-related information in one spot. Aside from the agreements themselves, you can access vendor details like names, addresses, emails, and phone numbers quickly.

To streamline communication with your contractors, you can even give them limited access to your platform. You can then send work orders to them directly along with attached work instructions, giving you a clear record of a contractor’s time spent, parts used, invoices, and other important data.

You can also generate reports, track how much money you’re spending on each contractor to keep an eye on whether they’re reaching the agreed service levels.