Maintenance, repairs, and operations (MRO) are critical components in the upkeep of any facility, ensuring that everything from the buildings to the systems and equipment are functioning optimally. Effective MRO practices not only help in maintaining the infrastructure but also play a significant role in the smooth operation of production processes.

By implementing better MRO practices backed by a modern unified facility asset management solution, organizations can reduce downtime, enhance productivity, and achieve cost savings, ultimately leading to more efficient and reliable operations.

What is maintenance, repairs, and operations (MRO)?

MRO is the combination of processes and activities connected to the upkeep of a plant or facility, including maintenance of the facility, the systems that run inside of it, and the assets and equipment used inside the facility to produce the main business output.

A simple example helps make this easier to understand. Take an ice cream plant. MRO covers the maintenance on the facility, including the buildings and the areas around them, the systems inside the facility, including things like the electrical and plumbing, and the machines the company uses to move the ingredients around the facility, produce the ice cream, store it, and then load it into trucks for delivery.

What is the difference between direct and indirect spend, and what’s the connection to MRO?

Here’s another way to understand MRO. With our ice cream plant example, the company has two types of spend. On one side is the direct spend, which is money for the parts and materials the company uses to produce ice cream. So, for example, cream, sugar and walnuts.

On the other side is the indirect spend, which are all the services and products the organization needs to buy. And it can cover a lot. So, when the human resources department prints out a new employee handbook, the paper and ink are indirect spends. The cleaning products for the janitor and the earplugs for the equipment operators are examples of indirect spend. The key point is that the organization needs to spend that money to keep everything going, but you don’t see it in the finished product.

MRO is another example of indirect spend. In fact, it’s often a large percentage of an organization’s overall indirect spend. But it’s not all of it. Remember, indirect spend is both products and services, so the entire accounting department is indirect spend, too, but it’s not MRO.

Why is MRO critical, especially for enterprise-level organizations?

MRO is important for all companies, but enterprise-level companies can see a lot of value from improving their MRO because they have so many assets.

Effective MRO delivers real value to large enterprises for many reasons, including:

- Cost efficiency: Enterprises spend a considerable portion of their budget on maintenance and repairs because they have many assets, so streamlining MRO processes can reduce wastage, optimize inventory levels, and prevent overstocking or stockouts

- Compliance and safety: Large companies often face stringent regulatory requirements related to safety and environmental impact. Effective MRO helps ensure compliance with these regulations by maintaining equipment to meet safety standards and reduce the risk of workplace accidents

- Longevity of assets: Proper maintenance extends the life of machinery and equipment, which is particularly important for enterprise-level companies that invest heavily in assets. Prolonging the lifespan of these assets can defer significant capital expenditures and contribute to better financial health

That means MRO is not just a support function but a critical component of strategic operations in large companies, directly impacting their operational success and long-term sustainability.

What are the types of MRO?

Although they all fall under the larger umbrella definition of “keeping things up and running,” there are four different types of MRO.

- Infrastructure repair and maintenance

- Production equipment repair and maintenance

- Material handling equipment maintenance

- Tooling and consumables

Understanding the various roles of MRO starts with looking at each type.

Infrastructure repair and maintenance

Includes maintenance and repair on roofs, doors, windows, parking lots, lighting, and plumbing. It can also include landscaping, snow removal, pest control, and janitorial services.

Although internal teams often do all the work, there are many opportunities to bring in third-party vendors. So, you might have the maintenance department doing small repairs on the roof but bring in professional roofers for larger projects. Also, it depends on if the organization owns or leases the property. The maintenance team is only responsible for work not already covered in the lease.

Production equipment repair and maintenance

Includes the assets and equipment directly involved in the production process. The goal of this type of MRO is avoiding unscheduled downtime and keeping the line online.

Maintenance departments are a big part of these MRO processes, and for each asset or piece of equipment, they choose the maintenance strategy that makes the most sense. For example, for something like the lighting around a machine or the fuses inside it, it makes the most sense to simply use run-to-failure. But for other machines, the department might choose predictive maintenance, which delivers a lot of value but also requires an upfront investment on top of ongoing costs.

Generally, maintenance departments employ a combination of on-demand work orders and preventive maintenance inspections and tasks to keep everything up and running.

Material handling equipment maintenance

Covers all the assets and equipment connected to moving raw material to the production line and completed products to the loading docks for eventual shipping. Basically, it’s what you need to bring in the materials and then what you need to send out the product.

Tooling and consumables

All the smaller tools and consumables for the production process that are not in the finished product. Drills, drivers, wrenches, socket sets, bits, and cutting blades are all examples of common tools. Glue, gloves, goggles, safety glasses, dust masks, and other personal protection equipment (PPE) are all examples of consumables or MRO inventory.

Why is MRO inventory important?

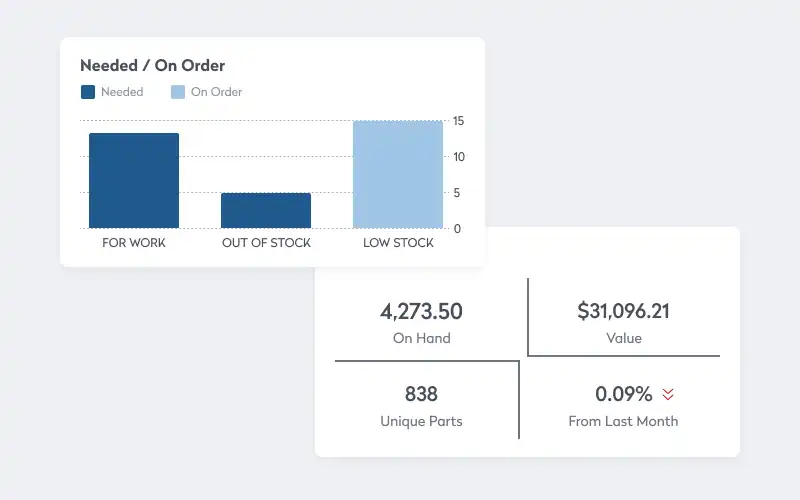

MRO inventory is what you need to keep your facilities, their systems, and assets and equipment up and running. It’s crucial for ensuring the smooth and efficient operation of a company’s machinery and equipment. Effective management of MRO inventory helps prevent unexpected downtime and costly disruptions by ensuring that necessary parts and supplies are readily available when needed, enhancing equipment reliability and longevity and supporting consistent productivity and operational efficiency.

By maintaining an optimal level of MRO inventory, businesses can avoid the pitfalls of overstocking and understocking, which can lead to significant financial and operational inefficiencies.

How can organizations improve MRO procurement?

Procurement is a whole area of expertise, but it’s worth looking at some of the important trends to ensure we have a good surface-level understanding of how they work.

Rely on vendor-managed inventory (VMI)

Here, you’re outsourcing the headaches of inventory control to a third party. Instead of deciding what to order, when to order it, and where to put it when you’re holding it in inventory, you turn over all those decisions to the supplier. On top of the obvious benefit of peace of mind, VMI should deliver cost savings through bulk purchases.

Switch to MRO vending machines

For many organizations, cutting MRO inventory costs starts with reducing shrinkage, when inventory is lost through employee theft and misuse. MRO vending machines, and yes, they look a lot like vending machines for drinks and snacks, are a way of controlling inventory. Once the machines are set up, techs can only access inventory using an employee card or fingerprint. If they’re not authorized to use certain parts, the machine won’t dispense them.

But the vending machines do more than slow down or stop shrinkage. They also speed up work. With some vending machines, you can program them to dispense specific combinations of parts and materials, helping techs get everything they need for a work order quickly.

How can organizations improve MRO processes and workflows?

Start by looking at your existing workflows for maintenance. How well are your preventive maintenance tasks planned out? And more importantly, what are your monthly completion rates? For on-demand work orders, how streamlined is the process? For example, if someone notices a problem on the line, how quickly and easily can they contact the maintenance department? From there, how quickly can you review the request, generate, assign, and track a related work order?

For a lot of organizations, even a quick look at their processes and workflows reveals gaps and roadblocks, and it’s because they’re still struggling with older maintenance management methods, like paper and spreadsheets or a piece of software that does not match their needs.

In fact, for larger enterprise-level organizations, the problems come from having many pieces of software that cannot connect to one another. Each piece of software does a good job of capturing data, but it all remains siloed, so facility and maintenance managers cannot leverage it into insights. Because no one can see the true big picture, decision-making suffers.

Implement modern asset management software

A modern unified software solution makes everything easier by first moving all your data to the cloud, where it’s safe, secure, and searchable. With older maintenance management systems, like paper and spreadsheets, you run the risk of bad data every time you copy over data manually or copy and paste between cells.

From there, the software helps you tackle on-demand work orders more efficiently, schedule and track PMs, and better control your MRO inventory.

Streamline on-demand workflows

Look at your current workflow for on-demand work orders and count all the places where data moves manually or by word of mouth. Those are all the spots where you risk confusion and corruption, slowing your team down, leading to breakdowns.

Modern work order management software keeps everything inside one system, ensuring everyone is looking at the same reliable data.

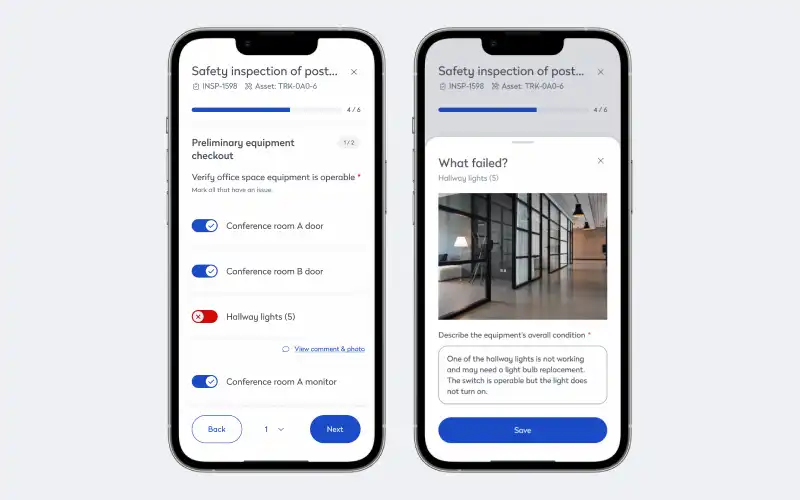

It starts with the online maintenance request portal, where people can submit requests for work. And because it has customizable data fields, the maintenance department is guaranteed to get the information it needs to make good decisions. From there, you can approve requests and then generate, prioritize, assign, and track work orders. Techs get work orders packed with everything they need to close out quickly, including detailed instructions, checklists, and digital-format manuals.

Digital work orders also come with lists of associated parts and materials, ensuring techs arrive onsite with everything they need to get the job done. And when they close out, the software automatically updates your MRO inventory levels, so you always know how much you have in stock of any given item. And when you hit your customizable min level, the inventory management software sends you an alert, so you can set up your next purchase order. With all the vendors’ contact info inside the software, you can organize and send new orders directly from the inventory management solution.

Set up, schedule, and track preventive maintenance

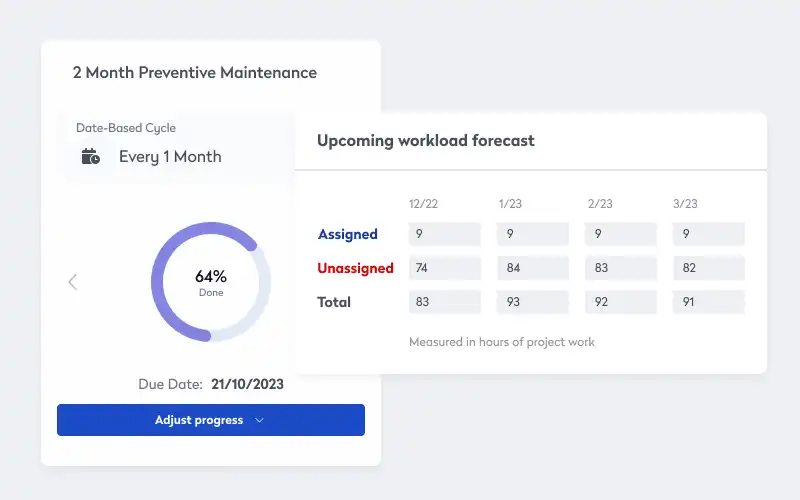

Every department has its own key performance indicators (KPIs), and maintenance departments should spend a lot of time thinking about ways to reduce their on-demand work orders, switching instead to preventive maintenance inspections and tasks. The current thinking is to aim for a 20/80 split between reactive and preventive work orders.

Asset management software helps you achieve best practices for preventive maintenance by automating the process. Start by setting up your PMs inside the software. For many of them, you can use templates. Once you’ve created your checklists and instructions, copying them over into new PMs takes just a few clicks. From there, you can schedule them based on usage or time, and the preventive maintenance software automatically generates and assigns them for you.

Improve MRO to boost productivity, cut costs across the enterprise

Although MRO spend affects teams across an organization, the facility and maintenance management departments are often the most closely connected. So, any processes or procedures they can implement to control MRO costs can have an outsized impact on that section of the overall budget. To improve MRO, you can negotiate better deals with suppliers and better control how you distribute MRO inventory. For processes, a unified facility management software solution helps your maintenance team do more, faster, and at a lower cost.