Every continuous operations facility has this moment: Second shift walks in, sees a cryptic sticky note on a machine, and has no idea what first shift was dealing with. Or worse, they don’t see the note at all. When the equipment on the manufacturing line fails three hours into the second shift, production stops. Nobody knows what the day shift technician tried.

Poor handoff practices cost industrial manufacturers $50 billion annually according to a Deloitte industry report, while unscheduled downtime costs facilities $260,000 per hour across approximately 800 hours per year, with communication breakdowns responsible for 20% to 30% of incidents. Employees waste 1.8 hours every day searching for information their predecessors should have documented, according to a McKinsey report.

The solution is a unified digital asset and equipment platform that ensures critical knowledge flows seamlessly between shifts.

Key takeaways

- Critical equipment knowledge that remains undocumented leaves incoming shifts without context, forcing teams to rediscover issues, repeat diagnostics, and make decisions blind to what previous shifts observed or attempted

- Poor shift handoffs drain billions annually from manufacturers, with communication breakdowns responsible for a significant portion of unplanned downtime incidents that bring production to a halt and create cascading operational costs

- Unified digital platforms with mobile-first access eliminate information gaps by capturing structured shift data, delivering real-time alerts to incoming teams, and connecting handoff documentation directly to asset management and work order systems

Without structured information transfer between shifts, companies face higher costs, lower productivity, and cascading quality issues that erode competitive position.

Why continuity now defines operational excellence in manufacturing

Continuity represents more than just good communication between shifts. Manufacturing continuity means maintaining unbroken operational knowledge across shifts so incoming teams can pick up exactly where previous teams left off.

When the second shift inherits complete context about equipment status, developing issues, and work in progress, they can make informed decisions that prevent small problems from becoming major failures.

Manufacturing facilities lose continuity when critical knowledge exists only in the memories of departing shift workers.

The day shift technician who noticed a bearing running hot never documented the observation. The first shift operator who adjusted machine parameters to compensate for material variations didn’t record the changes. The outgoing supervisor who planned to order replacement parts forgot to mention it during the rushed five-minute handoff. Each gap in continuity creates risk.

Continuity transforms tribal knowledge into institutional knowledge. Equipment doesn’t care which shift operates it, and customers don’t distinguish between products manufactured during day versus night shifts. Achieving consistent output across all shifts demands continuity systems that capture and transfer complete operational context automatically.

The financial impact of poor continuity in manufacturing extends across operations

Equipment runs at reduced capacity when incoming operators lack context about developing issues. Quality defects multiply when teams miss critical process adjustments. Rework and scrap rates climb when shift transitions lose information about parameter changes.

Safety creates additional costs and risks. Research from industry sources shows manufacturers report safety incidents increased over recent years. Many incidents occur during or shortly after shift handovers, when incoming teams lack awareness of hazards or equipment status.

How unified facility management platforms deliver shift handoff excellence

Manufacturers achieve shift handoff excellence through unified platforms that capture critical information systematically and deliver it exactly when and where incoming teams need context. The framework replaces informal verbal handovers with structured digital systems built on three elements.

Structured automated data capture replaces ad-hoc notes

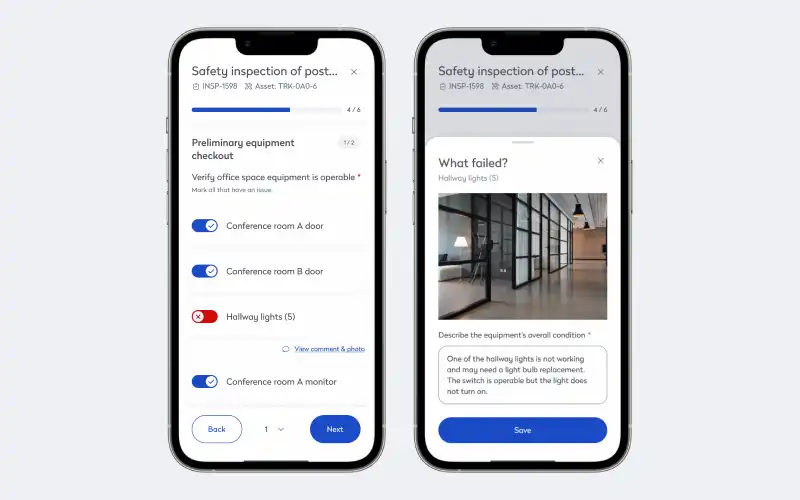

Digital work order systems replace free-form note-taking with systematic data capture. Teams document equipment status at shift end using customizable work order templates with required fields rather than optional narratives. Work in progress gets recorded with specific next steps and attached documentation including checklists, diagrams, and schematics. When teams identify issues during their shift, they can include actions taken, parts used, and outcomes.

Equipment-specific documentation covers current operational status, recent maintenance or repairs, unusual behavior or developing issues, and parameter changes. Safety and compliance documentation captures incidents or near-misses, lockout and tagout status, environmental concerns, and regulatory inspection notes, while preventive maintenance scheduling ensures teams document developing issues before they escalate into failures.

Mobile accessibility delivers information at the point of work

Mobile technician apps enable technicians to access complete handoff information at machines rather than returning to offices to check notes. Real-time updates become visible to incoming shifts immediately.

Mobile platforms support photo documentation and video capture, allowing visual evidence to supplement text descriptions. Barcode or QR code scanning identifies specific assets and retrieves complete maintenance histories with a single scan. Offline functionality maintains productivity when network connectivity drops, but syncs automatically when connections restore, ensuring no information gets lost during shift transitions.

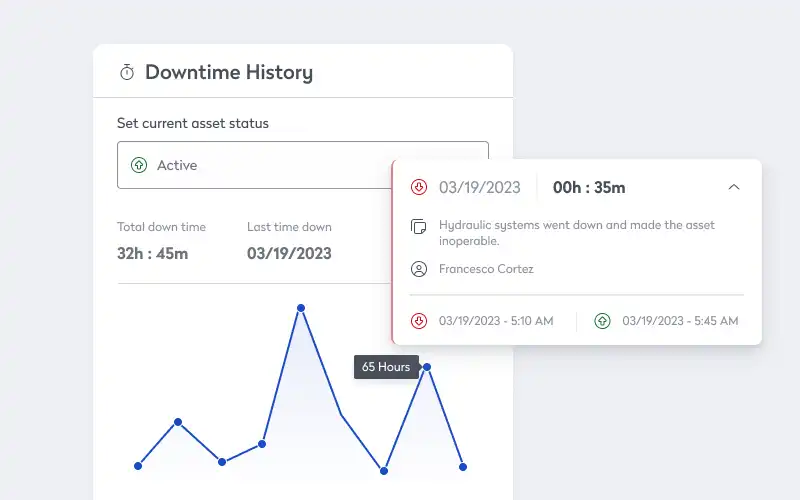

A night shift operator discovering a hydraulic leak at 11 takes photos through the mobile app, tags the issue with severity markers, and documents containment steps including parts used from inventory. The day shift supervisor receives alerts at 6:30 with full context, photos, priority indicators, and complete labor and parts records. Parts orders go out before arriving on-site, reducing response time from hours to minutes.

Visual dashboards provide at-a-glance operational status

Real-time visibility across entire operations allows managers to spot developing issues before they escalate. Unified facility management platforms consolidate dashboard elements that display equipment uptime by shift and production line, work order status and aging, preventive maintenance compliance rates, quality metrics and defect trends, and safety incident tracking.

Drill-down capabilities let managers investigate root causes and access complete work order histories including labor hours, parts costs, and vendor performance. Automated alerts notify stakeholders when metrics exceed thresholds, ensuring critical information reaches decision-makers immediately rather than waiting for shift handoff meetings.

Measuring results through operational metrics

Measuring improvement in shift handoff excellence requires tracking both leading indicators that predict performance and lagging indicators that confirm results. Unified facility management platforms capture these metrics automatically rather than requiring manual compilation from disparate sources.

Leading indicators predict handoff quality

Handoff completion rate measures the percentage of shifts with fully completed digital handoffs, indicating team adoption and process compliance. Time to handoff completion tracks how long teams spend on documentation. Issue escalation rate shows the percentage of flagged items properly escalated. Information completeness calculates the percentage of required fields populated.

Lagging indicators confirm operational outcomes

Unplanned downtime reduction measures the goal, with digital handovers typically contributing to significant improvements as teams catch developing issues earlier and respond faster with better context. Mean time to repair decreases when technicians arrive with complete information rather than starting diagnosis from scratch. Schedule compliance improves as preventive maintenance happens on time, driving down reactive work rates.

Real success story: How digital preventive maintenance improved productivity, reduced risk

A global equipment manufacturer with 1,300 employees faced growing challenges maintaining operational efficiency across multiple shifts. Paper-based preventive maintenance processes were time-consuming, error-prone, and created compliance risks. Limited visibility into asset health made planning difficult. Manual record-keeping threatened audit readiness.

The facility deployed Eptura Asset to digitize preventive maintenance workflows. Teams created standardized inspection templates applied across hundreds of assets, enabling automatic failure work orders and real-time tracking. Technicians adopted mobile apps for on-the-go updates, while managers leveraged dashboards for data-driven decisions.

After a successful implementation, they realized:

- 100% transition from paper-based to digital preventive maintenance

- Improved audit readiness and compliance confidence

- Faster work order creation through automated inspection workflows

- Increased technician productivity with mobile app adoption

- Standardized processes across multiple facilities

The success of the initial implementation led to training rollout across other facilities, establishing consistent maintenance excellence practices throughout the organization.

Read the complete success story.