Work orders are the basic building blocks of a successful maintenance operation. Maintenance leads use them to control resources efficiently, while technicians need to them know what to do. Without a clear prioritization strategy, however, teams waste time on work that doesn’t help them prevent costly failures and support business goals. Prioritization is what turns a list of requests into an effective, actionable plan.

A digital maintenance solution simplifies and strengthens prioritization by centralizing asset data, automating request intake, and applying rules to rank tasks based on urgency and business impact.

Key takeaways

- Implementing a work order hierarchy helps prevent small problems from escalating into costly failures by tackling high-risk or high-impact issues first

- A priority matrix evaluating asset criticality and operational risk enables maintenance teams to make informed decisions about which work orders to complete first

- Modern maintenance solutions with features like centralized work order management, mobile access, comprehensive dashboards, and integrated safety tracking support effective work order prioritization

Maintenance and repair costs remain a major operational expense. In some manufacturing environments, they account for up to 20% of total operating costs. Implementing a work order hierarchy, where the team tackles high-risk or high-impact issues first, helps prevent small problems from escalating into costly failures and extensive repairs.

By building a system that ranks work orders based on urgency, asset criticality, and risk, maintenance managers can make better use of technician time, reduce downtime, and keep operations running smoothly.

What is work order prioritization?

Every organization has maintenance tasks they need to complete to keep operations running, but not all work orders carry the same level of importance. Requests vary in urgency, complexity, and overall impact. The process of evaluating them and deciding the order the team should complete them is work order prioritization.

Work order prioritization is the framework your team uses to determine which tasks to address first. It helps align maintenance activities with business goals by focusing on the work that has the greatest impact on uptime, safety, and cost control. It’s an approach that ensures the department has its technicians spending time where it matters most.

What are the challenges of outdated work order prioritization?

Poor work order management can quietly drain resources and inflate costs, especially without a digital system to support prioritization. When the department must assign tasks manually or try to track them across disconnected tools, maintenance teams often spend time on low-impact jobs while critical issues go unresolved. The misallocation of technician time and skill undermines productivity and drives up expenses.

Without centralized data and automated workflows, facilities tend to default to reactive maintenance, an expensive approach. But without a system to rank tasks by urgency and impact, it’s difficult to make the shift to proactive maintenance. The team remains trapped with longer downtimes, emergency labor costs, and increased wear on assets.

How can maintenance managers create a work order prioritization program?

Without a clear system for ranking work orders, productivity suffers, and costs rise. A structured prioritization program helps maintenance teams focus on what matters most.

Start with safety

You should always treat safety-related work orders as high priority, even if they don’t directly affect production. For example, a damaged guard rail on a machine may not stop operations, but it poses a serious risk to operators.

OSHA violations are costly and disruptive. In fiscal year 2024, the top 10 most frequently cited standards included fall protection, hazard communication, lockout/tagout procedures, and machine guarding.

These violations also contribute to workplace injuries, unplanned downtime, and long-term reputational damage.

Use a priority matrix

A priority matrix helps you evaluate work orders based on two key dimensions: asset criticality and operational risk. A structured approach removes guesswork and ensures you take care of the most important tasks first.

Examples of asset criticality, from high to low, include:

- Health and safety compromised

- Primary production down

- Secondary or support systems down

- Non-essential production affected

- Worker comfort impacted

By separating asset criticality from operational risk, you can evaluate each work order from multiple angles, which helps ensure urgent tasks tied to safety or production aren’t delayed by lower-impact requests.

Examples of operational risk, from high to low, include:

- Immediate safety threat

- Immediate production loss

- Potential production loss

- Risk of regulatory non-compliance

- Preventive maintenance

- General improvements or optimizations

By assigning scores to both asset criticality and operational risk, teams can make more informed decisions about which work orders to complete first, creating consistency in the prioritization process and helping ensure that high-impact tasks are never delayed by lower-priority requests.

Train the teams

Asset operators often create the initial work orders, so they need clear guidance on how to assess urgency. Training staff to use the matrix ensures consistent prioritization and helps technicians focus on high-impact tasks.

Managers play a key role in final scheduling, though, because they can consider technician availability, inventory levels, and operational context. With visibility across the plant, you can make informed adjustments that support overall efficiency.

Enforce accountability

Even with training, some technicians may complete work orders out of sequence or rely on intuition, leading to delays, wasted labor, and unreliable data.

Auditing work orders helps managers identify patterns and reinforce best practices. A modern maintenance platform allows you to assign tasks, track completion, and review performance, making it easier to spot inconsistencies and provide targeted coaching.

How does a modern maintenance platform support a work order prioritization program?

Digital transformation is essential for building a scalable, consistent work order prioritization strategy. Modern maintenance platforms offer purpose-built features that help teams triage requests, assign tasks efficiently, and ensure technicians do the most critical work first.

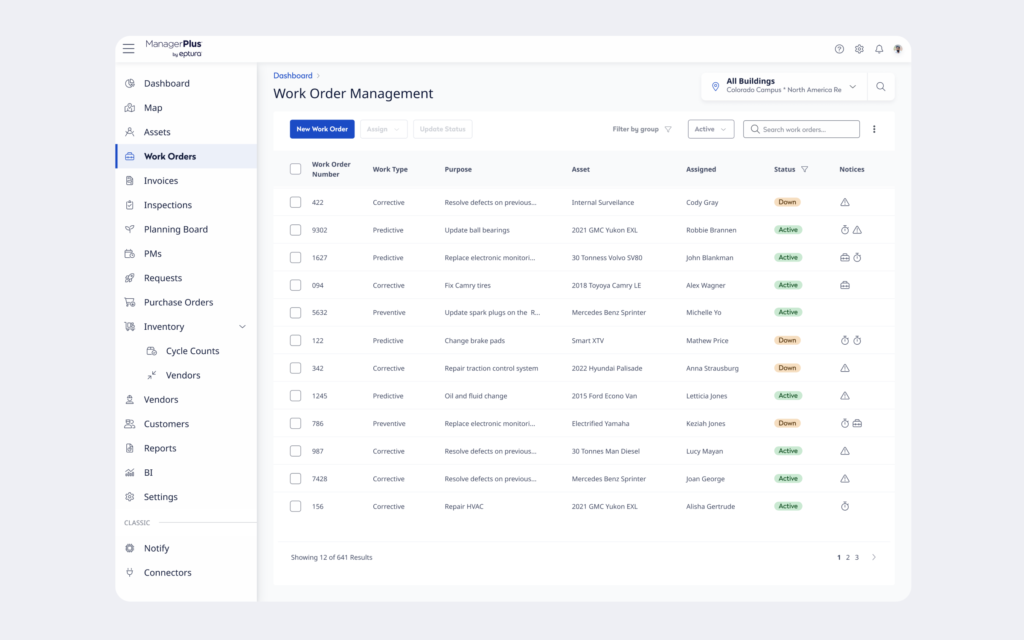

Centralized work order management

A centralized system allows maintenance teams to manage all incoming requests from a single interface. You can sort and filter work orders by priority level, asset type, location, and due date. Improved visibility makes it easier to identify which tasks require immediate attention and which can be scheduled later. Many platforms also support automated routing rules, so work orders tied to safety, compliance, or high-risk assets are flagged and escalated automatically, cutting manual triage and ensuring consistency across teams.

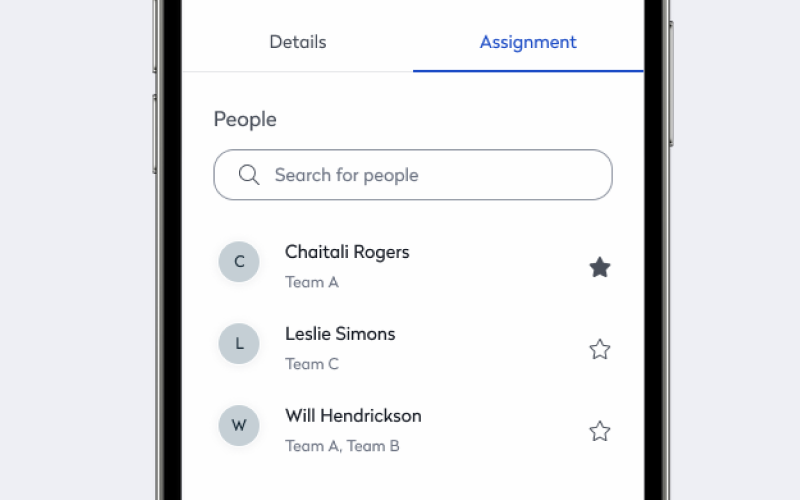

Mobile access for technicians

Mobile maintenance apps give technicians real-time access to their assigned work orders, complete with priority indicators, asset history, and step-by-step instructions. Technicians can update status, log notes, and close out tasks directly from their devices, which helps reduce delays and improves data accuracy. Some apps also include barcode scanning and photo documentation, allowing technicians to verify work and capture issues on the spot. The level of access ensures the team tackles high-priority tasks quickly, even when spread across multiple sites.

Integrated safety and compliance tracking

You can set up the system to automatically flag work orders tied to safety inspections or regulatory tasks. In fact, modern platforms often include built-in compliance tools such as inspection checklists, audit trails, and documentation templates. The integration makes it easier to identify and prioritize safety-related tasks and helps ensure the team doesn’t overlook compliance work.

It also simplifies reporting for internal reviews and external audits, reinforcing the importance of safety in the prioritization process.

Comprehensive dashboards for maintenance leads, managers, and supervisors

Dashboards provide supervisors with a real-time overview of open work orders, technician availability, and asset conditions. Visibility helps managers make informed decisions about which tasks to prioritize and when to adjust schedules. For example, if a technician is already on site and a high-priority task is submitted, the dashboard makes it easy to reassign work based on location and skill set. Dashboards also help track completion rates and identify bottlenecks, which supports continuous improvement in prioritization strategies.

By combining these features, digital platforms transform work order prioritization from a manual, reactive process into a structured, data-driven workflow. Maintenance teams gain the tools they need to focus on the right tasks at the right time, helping you reduce downtime, improve safety, and control costs.

Prioritizing success with stronger work order management

By implementing a structured work order prioritization strategy, maintenance teams can improve operational efficiency, reduce costs, and enhance overall safety. Leveraging modern maintenance solutions with advanced features like routing, mobile access, and integrated compliance tracking enables organizations to transform their maintenance operations from reactive to proactive, data-driven workflows, helping reduce downtime and improve safety while controlling costs and supporting business goals effectively.